Resistors In Battery Management Systems: Key Components To Ensure Safe And Efficient Batteries

Battery Management Systems (BMS) are responsible for monitoring key battery parameters such as voltage, current, and temperature to ensure safety and performance across all operating conditions. Among the core components in a BMS, the current sense resistor plays a crucial role by converting charge and discharge currents into precise voltage signals for real-time monitoring by the controller. These resistors help detect abnormal conditions such as overcurrent or short circuits, enabling protection mechanisms that prevent damage to the battery pack.

Compared to other current detection methods like Hall sensors, resistive current sensing offers advantages in cost-efficiency, linearity, and the ability to measure both DC and AC currents. For this reason, it has become a common choice in BMS designs for electric vehicles and energy storage systems.

In BMS applications, the most commonly used current sense resistor types include Metal Alloy Current Sense Resistors, Slim Metal Alloy Current Sense Resistors, and Metal Alloy Shunt Resistors. The following sections explain their key features, typical BMS applications, and benefits in terms of safety, efficiency, and design flexibility.

What is a battery management system (BMS)?

The Battery Management System (BMS) is an electronic system used to monitor and manage battery performance. It can real-time monitor parameters such as battery voltage, temperature, and charge-discharge status, and make adjustments and protections to ensure that the battery does not experience overcharging, deep discharging, overheating, or other abnormal conditions during operation. The core objective of BMS is to extend battery life, enhance performance, and ensure battery safety.

What are the resistors in the battery management system?

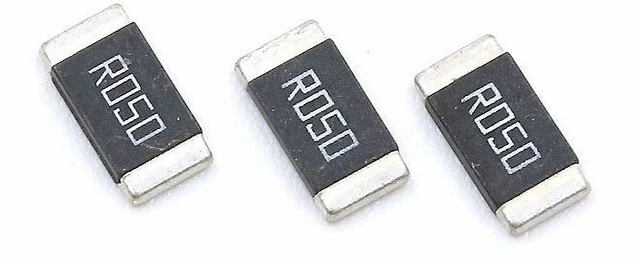

1.Metal Alloy Current Sense Resistors

Metal Alloy Current Sense Resistor are made from stable, low-resistance metal alloy materials, offering excellent electrical performance. Typical specifications cover package sizes from 0805 to 4527, with power ratings ranging from 0.5W to 7W and resistance values from 0.5mΩ to 500mΩ. These resistors comply with AEC-Q200 automotive standards.They are widely used on BMS control boards or module-level current sampling circuits, where they monitor total charge/discharge current and help balance current among individual cells or submodules. With low inductance (less than 5nH), they are also suitable for detecting fast-changing currents in EV drive systems and charging interfaces.

- Safety: Metal Alloy Current Sense Resistors provide high accuracy and low temperature drift, enabling precise detection of overcurrent conditions. Their stable temperature coefficient (typically ≤25ppm/°C) and low thermoelectric voltage prevent measurement errors caused by thermal variation, which supports fast and reliable fault protection.

- Efficiency: Ultra-low resistance minimizes voltage drop and power loss during high-current operation, improving energy efficiency. The excellent conductivity and low self-heating of metal alloys further enhance measurement linearity and thermal stability.

- Design: Available in a wide range of resistance values and packages, they provide layout flexibility for BMS designers. Surface-mount versions save board space and are suitable for low- to medium-power systems. They can also be used with four-terminal (Kelvin) connections to improve measurement precision on compact PCBs.

2.Slim Metal Alloy Current Sense Resistors

Slim Metal Alloy Current Sense Resistor are ultra-thin resistors designed for space-constrained applications. They come in compact package sizes ranging from 0402 to 1206, with power ratings between 0.25W and 1W and resistance values from 5mΩ to 50mΩ. Their thickness is typically less than 0.4mm.These resistors are ideal for compact BMS systems used in portable devices, small energy storage modules, and power tools, where minimizing PCB height and footprint is essential.

- Safety: Despite their lower power rating, slim resistors still offer reliable precision and stability. They are suitable for low-current pathways or subcircuit current sensing, supporting additional safety layers when combined with other protection circuits.

- Efficiency: The low resistance values result in minimal energy loss during sensing. With excellent thermal resistance and low thermoelectric voltage, they maintain high accuracy even under elevated temperatures.

- Design: Their key advantage lies in space savings. Slim form factors can be integrated into multilayer PCBs or dense layouts, offering flexible placement options. The flat, low-profile package reduces parasitic effects like inductance and resistance, improving transient response in fast current detection.

3.Metal Alloy Shunt Resistors

Metal Alloy Shunt Resistor are high-power current sensing components designed for high-current applications. They are available in large package sizes from 2512 to 8436, with power ratings ranging from 2W to 36W and resistance values as low as 0.025mΩ. Their temperature coefficient typically ranges from 15 to 50ppm/°C.These resistors are often used as current shunt elements in high-current paths, such as battery pack main lines or DC charge/discharge interfaces. They are especially suited for electric vehicle traction batteries and industrial power systems requiring precise high-current measurement.

- Safety: With high power handling and robust construction, Metal Alloy Shunt Resistors can withstand current surges and short-circuit conditions without damage, enhancing the system's durability and safety margin. Their low TCR and excellent thermal design ensure long-term accuracy under heavy loads, allowing timely fault detection.

- Efficiency: Extremely low resistance values minimize voltage drop and power loss, even under large current flow. These resistors are built with high-efficiency thermal structures and materials that dissipate heat quickly, ensuring stable operation over time.

- Design: As they are used in the main power path, these resistors require reserved space on the PCB or enclosure. Standardized designs, such as variants with mounting holes or copper terminals, simplify integration into high-current buses. Their reliability and repeatability make them ideal as predictable current measurement elements, reducing design complexity in thermal management and EMC considerations.

The role of resistor in battery management system

Resistors play a vital role in battery management systems (BMS). Here are the three key roles of resistors:

1. Current limiting and safety control

One of the primary tasks of a battery management system is to ensure that the battery is not damaged by excessive current during charging and discharging. Excessive current can not only cause the battery to overheat but also damage its chemical structure, shorten its lifespan, and even pose safety hazards. Resistors limit current in the following ways:

(1) Control Based on Ohm's Law: Ohm's Law indicates a direct relationship between current (I), voltage (V), and resistance (R). Resistors limit the flow of current through their resistance values. For example, when the battery voltage increases, the BMS can control the charging current by adjusting the resistor's resistance value, ensuring that the battery is charged within a safe range.

(2) Constant current charging: In the early stage of battery charging, BMS will carry out constant current charging through resistor. The charging current needs to be kept at a constant value to prevent the battery from overheating or damage due to excessive current. In this process, resistor adjusts the size of the current to ensure a smooth and safe charging process.

(3) Overcurrent protection: During the charging and discharging process of the battery, if the current exceeds the preset safety value, BMS reduces the current flow by increasing the resistance to avoid damage to the battery. This protection mechanism is particularly important in the case of rapid discharge or sudden heavy load.

2. Temperature control and heat dissipation management

Resistors in the BMS also help regulate temperature. During charging and discharging, a certain amount of heat is generated inside the battery. By introducing appropriate resistors in the battery management system, excess heat can be dissipated to avoid overheating.

(1) Heat Generation and Current Control: When current flows through a resistor, it generates heat according to the power formula (P=I²R). The BMS indirectly controls the heat generated by the resistor by adjusting the current, helping to maintain the battery at a safe operating temperature. By regulating the current flow, the BMS can reduce heat generation during the battery's charging and discharging processes, preventing overheating.

(2) Temperature control strategy when the current is too high: During the charging or discharging process of the battery, excessive current will lead to a sharp rise in the temperature of the battery, which may lead to battery damage or safety accidents. At this time, BMS will reduce the current flow through the resistor to reduce the temperature rise of the battery and help the battery maintain an ideal temperature range.

(3) Thermal Protection and Optimized Heat Dissipation: Battery management systems often monitor signals from temperature sensors to adjust current flow in real time. By leveraging the regulating effect of resistors, they optimize battery heat dissipation. When the battery temperature is too high, the BMS can increase resistance to reduce current, thereby preventing overheating and avoiding damage or performance degradation of the battery due to excessive heat.

3. Battery balance and voltage regulation

The battery pack is usually composed of multiple battery cells, and the inconsistent voltage between the battery cells may affect the overall performance and life of the battery pack. The resistor plays a key role in balancing management:

(1) Passive Battery Balancing: Some cells in the battery pack may have higher voltages than others. To ensure overall balance, resistors use passive balancing to convert excess electrical energy into heat dissipation, thereby reducing the voltage of high-voltage cells. This way, the voltage across the entire battery pack can be kept consistent, preventing damage from overcharging or deep discharging of individual cells.

(2) Battery voltage regulation: BMS accurately adjusts the voltage of each battery unit through resistors, so that the voltage of each unit in the battery pack is consistent during charging and discharging, ensuring that each unit runs in the best working state, thus extending the service life of the battery pack.

(3) Improve efficiency and extend life: The resistor adjustment during the battery balancing process not only helps to improve energy utilization efficiency, but also prevents internal consumption caused by voltage imbalance, reduces excessive loss of battery cells, and optimizes the overall performance of the battery pack.

Why is it important to choose high quality resistors for BMS?

The battery management system (BMS) plays a crucial role in ensuring battery performance, safety, and longevity. As a key component of the BMS, the quality of resistors directly impacts the overall performance of the battery management system. Selecting high-quality resistors is essential for BMS. Here are several key reasons: When choosing high-quality resistors, consider the following factors:

1. Ensure safety and prevent overheating and overload

One of the core functions of a battery management system is to prevent faults caused by overcurrent or overheating during charging and discharging. High quality resistors can effectively avoid the following safety issues:

(1) High temperature resistance: When the battery management system works under high power or high current conditions, heat will be generated. High quality resistors can withstand higher temperatures to avoid damage or failure of resistors due to excessive temperature, and prevent system overheating or battery safety accidents.

(2) Current carrying capacity: High quality resistor has high power processing ability, which can withstand large current flow in the battery management system, and avoid the resistor damage due to overload when the current is too large, so as to ensure that the BMS can still operate stably under high load.

2. Optimize battery performance and extend service life

The performance of the battery is directly related to the charge and discharge efficiency, life and safety of the battery, and the resistor plays an important role in regulating the current, balancing the battery voltage and controlling the temperature. High quality resistor helps in the following aspects:

(1) Battery charge and discharge efficiency improvement: High quality resistors ensure that the energy loss in the process of battery charge and discharge is minimized by accurately controlling the current, avoiding overcurrent and overvoltage, and improving the charge and discharge efficiency of the battery.

(2) Battery balance and protection: High quality resistors can help BMS effectively balance the voltage between battery cells, ensure that each battery cell is consistent in the process of charging and discharging, so as to avoid overcharge or overdischarge of a single battery cell, and prolong the service life of the battery pack.

3. Improve the accuracy and reliability of battery management system

BMS requires precise control of the battery's charging current, discharging current, temperature and voltage, and resistors are the basis for achieving this. High quality resistors typically have:

(1) High precision and stability: The resistance value of high quality resistor is more accurate and stable, and is not easy to be affected by external environmental changes (such as temperature and current), so as to ensure the accurate control of current regulation, temperature management and battery balance.

(2) Long Life and Low Drift: High-quality resistors have low resistance drift, meaning that even under prolonged operation or high load conditions, the change in resistance value is extremely minimal. The stability of the resistance value is crucial for the long-term reliability of BMS, preventing electrical loss and distortion caused by unstable resistors, thus ensuring the long-term stable operation of batteries.

Conclusion

Resistors in the battery management system are one of the key components that ensure the safe and efficient operation of batteries. By properly selecting and applying resistors, battery performance can be effectively improved, their lifespan extended, and safety ensured. When choosing resistors, it is essential to focus on their performance, quality, and compatibility to guarantee the reliability and stability of the battery management system.