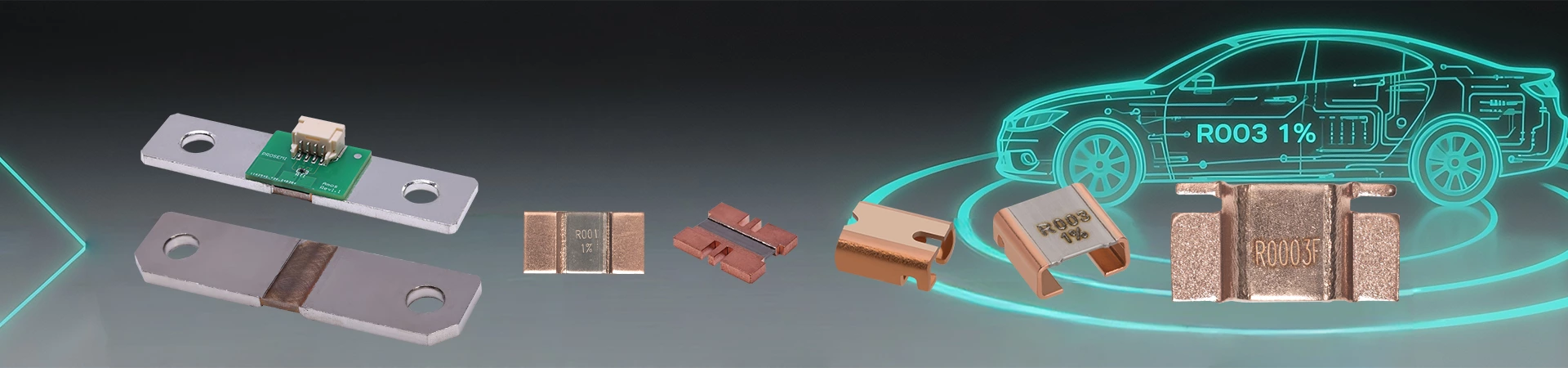

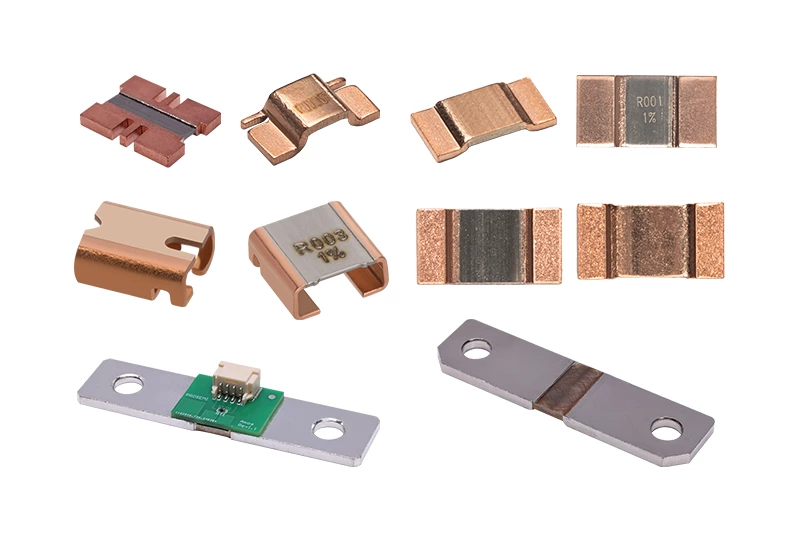

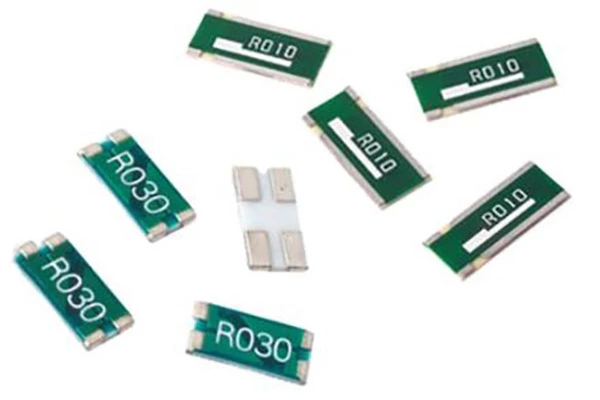

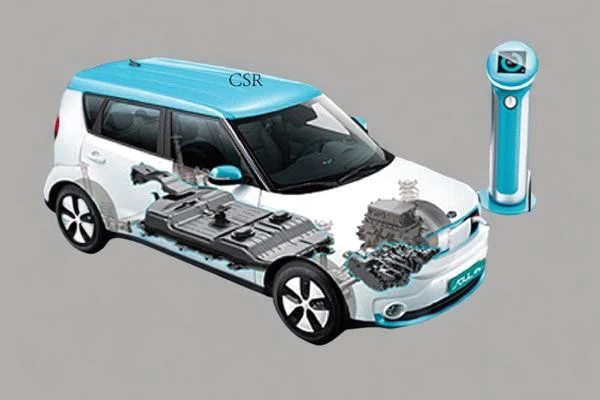

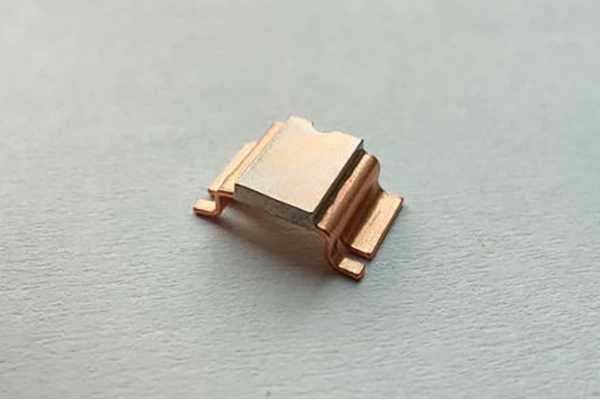

The precision alloy current sensing shunt resistors achieve stable operation under complex conditions with high reliability, reducing maintenance costs and increasing user trust. With their high overload capacity, they can withstand large current surges, enhancing system flexibility and extending equipment life. Thanks to their high precision, they enable accurate measurement and control, meeting stringent industry standards. As a result, they demonstrate significant advantages in ensuring efficient and stable system operation, reducing overall costs, and enhancing market competitiveness.