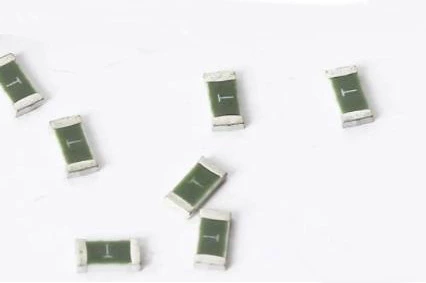

SMD Fuses: An Efficient Overcurrent Protection Solution for Compact PCB Designs

As electronic devices continue to evolve towards being thinner and more compact, PCB space becomes increasingly limited. Traditional through-hole fuses are no longer suitable for high-density layouts. SMD fuses (Surface Mount Device fuses) have become the preferred choice for modern compact circuit protection due to their small size, ease of mounting, and high precision.

1. What Are SMD Fuses?

-

Definition: SMD fuses are surface-mounted overcurrent protection components. Under normal conditions, they remain in a low-resistance state. When the current exceeds the rated value, the internal fuse element melts, cutting off the circuit and preventing damage to downstream components.

-

Example: A smart wristband brand adopted 0805-sized SMD fuses, resulting in reduced device thickness and improved production efficiency.

2. Key Advantages

| Advantage | Description |

|---|---|

| Compact Size | Supports high-density layouts; ideal for portable and miniaturized products |

| SMT Compatibility | Compatible with automated SMT processes, reducing manual assembly costs |

| Fast Response | Fusing time in the millisecond range for timely overcurrent protection |

| Electrical Precision | Low tolerance, low resistance and inductance to ensure signal integrity |

| High Reliability | Complies with UL, IEC and other safety standards, ensuring stable performance |

3. Typical Applications

-

Consumer Electronics: Battery management and charging protection in smartphones and wearables

-

Communication Equipment: Interface protection for USB, Ethernet, etc.

-

Automotive Electronics: Submodule protection in in-vehicle infotainment systems

4. Key Selection Criteria

-

Rated Current (Irated): Should be 1.25–1.5 times higher than the normal operating current.

-

Rated Voltage (Vrated): Must be equal to or greater than the system's maximum voltage.

-

Fusing Characteristics: Fast-blow types for sensitive circuits; slow-blow types for inductive loads.

-

Package Size: Common sizes include 0603, 0805, 1206—select based on current and available space.

-

Certifications: Prefer models compliant with UL, IEC, and RoHS standards.

5. Layout and Mounting Tips

-

Place the fuse close to the power input to cut off fault current quickly.

-

Keep traces short and wide to minimize parasitic resistance.

-

Use copper planes or thermal reliefs around pads to enhance heat dissipation.

6. Conclusion

For modern electronics with space constraints and stringent overcurrent protection requirements, SMD fuses offer an efficient and reliable solution thanks to their compact size, fast response, and SMT compatibility. Proper selection and layout can greatly enhance circuit safety and reliability.

For project-specific selection or technical support, feel free to get in touch.