Understanding Slim Metal Alloy Current Sense Resistors

Definition and Role of Resistance

The resistor is a passive electrical component that creates resistance in the flow of electric current. In almost all electrical networks and electronic circuits they can be found. The resistance is measured in ohms (Ω). An ohm is the resistance that occurs when a current of one ampere (A) passes through a resistor with a one volt (V) drop across its terminals. The current is proportional to the voltage across the terminal ends. This ratio is represented by Ohm’s law:

I=U/R

Resistors are used for many purposes. A few examples include limiting electric current, voltage division, heat generation, matching and loading circuits, gain control, and setting time constants. They are commercially available with resistance values over a range of more than nine orders of magnitude. They can be used as electric brakes to dissipate kinetic energy from trains, or be smaller than a square millimeter for electronics.

What is a Slim metal precision alloy current detection resistor?

Slim metal alloy current sense resistors are specifically designed for accurate current measurement in electronic circuits. They offer low resistance values, high precision, and good thermal stability, making them ideal for applications where precise current monitoring is crucial. These resistors are often used in power supplies, motor control, and battery management systems to ensure efficient and reliable operation.

Applications of Slim metal precision alloy current detection resistor

Thin metal alloy current sensing resistors are used in various electronic applications, and precise current measurement and control are of great significance.Specifically, they are usually the first choice when the following situations are needed:

1.High precision and accuracy: The metal alloy construction and low-temperature coefficient of resistance (TCR) minimize resistance changes due to temperature fluctuations, ensuring

precise and stable current readings.

2.Low resistance and power loss: These resistors typically have very low resistance values in the milliohm range, reducing the voltage drop and power dissipated as heat. This is

crucial for improving system efficiency, especially in high-current applications.

3.Current sampling and feedback: They provide a voltage signal proportional to the current flow, which can be used to monitor and control the current in a circuit. This is essential for

applications like battery management systems, motor controls, and power supplies.

4.Short circuit and overcurrent protection: Their ability to accurately detect overcurrent situations allows for the implementation of safety mechanisms to protect other components in

the circuit.

Common applications

1.Battery Management Systems (BMS): Accurate current sensing is crucial for monitoring battery charge/discharge cycles, calculating state-of-charge, and protecting against overcurrent or short circuits.

2.Motor Control Systems: Current sense resistors provide feedback for precise motor control, enabling smoother operation and preventing damage from overcurrent.

3.Power Supplies and Converters: They are used to regulate and stabilize the output current, ensuring efficient power delivery.

4.Automotive Electronics: Robust current sense resistors with low TCR are needed in harsh automotive environments (e.g., engine control units, battery management systems).

5.Industrial Automation: Precision and reliability are essential for controlling and monitoring industrial processes.

6.Consumer Electronics: Used in devices requiring efficient power management and accurate current monitoring.

7.Hot-Swap Circuits: Current sense resistors help protect systems during hot-swapping (replacing components while the system is running) by detecting and controlling current surges.

Slim Metal Alloy Current Sense Resistors in Circuits

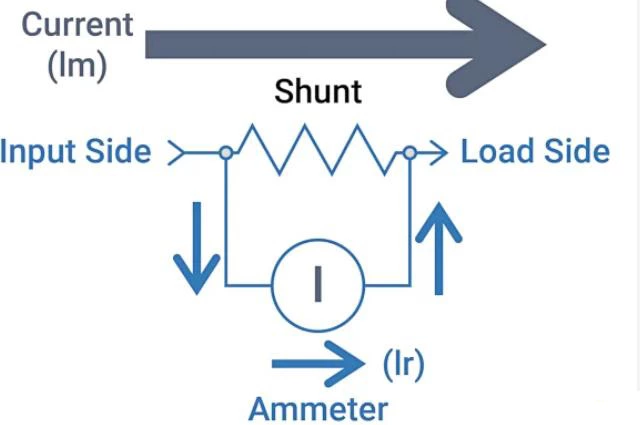

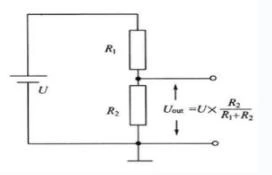

The principle of the current sense resistor is to convert a portion of the current or voltage in a circuit into a measurable signal by means of a resistor dividing the voltage in the circuit according to Ohm’s law. For current sense resistors, you can use Ohm’s law to calculate the amount of current in the circuit, i.e., I=V/R, where V is the voltage difference between the two ends of the resistor, and R is the resistance value of the resistor.

In a current‐sense circuit, the voltage across the sense resistor is given by the formula

U2=U1×R2 ÷ (R1+R2)

Here, U₁ is the total voltage of the circuit under test, R₁ is the series resistance of the rest of the circuit, R₂ is the resistance of the current‐sense resistor, and U₂ is the resulting voltage drop across R₂.

When implementing the performance of a current-sense resistor, the printed circuit board (PCB) must be designed with precision. Current sensing should be as comprehensive as possible, utilizing multiple layers and through-holes connected near the sensing component. This approach also enhances heat dissipation. The optimal method is to connect the four terminals to a two-port through-hole resistor and to use the reverse side of the PCB to route the current and voltage paths. If this is not feasible, the current and voltage detection connections should be made to the component pins on either side.

PROSEMI’s Slim Metal Alloy Current Sense Resistors series combines outstanding performance and compactness, with package sizes ranging from 0402 to 1206, rated power from 0.25W to 1W, and resistance values from 5mΩ to 50mΩ. These resistors have a thickness of less than 0.4mm and are designed for applications that require extremely small space and high efficiency, such as battery packs, inverters, consumer electronics, and other fields.