Advantages of Metal Alloy Current Sensing Resistors

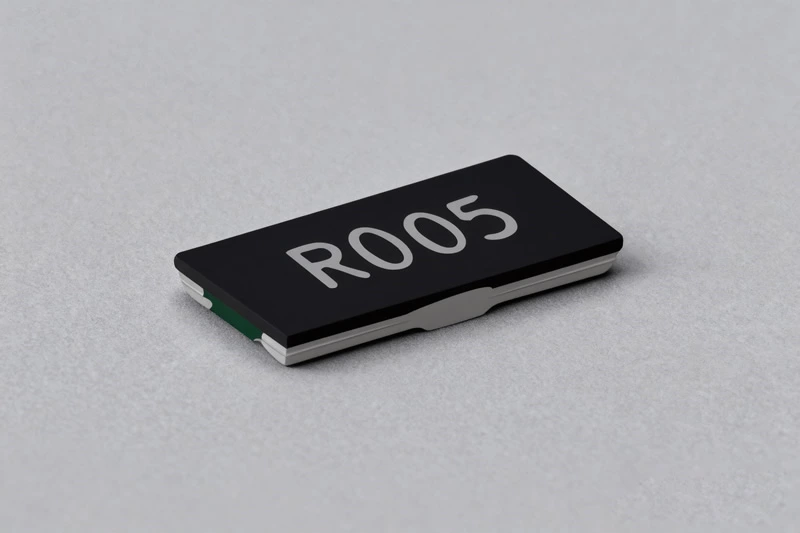

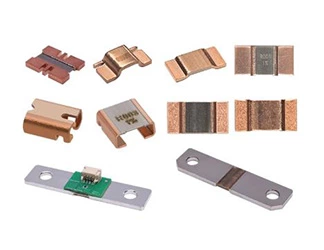

PROSEMI stands alone in mainland China as the brand that designs, develops, and produces full‑size, micro‑ohm precision alloy resistors (0402, 1206, 2512, 5930) for surface‑mount use. All models carry AEC‑Q200 automotive‑grade certification and offer resistance values as low as 500 mΩ, fully satisfying the demanding requirements of the power sector. There are five series of major products in the field of metal alloy current sensing resistors, namely Metal Alloy Current Sense Resistors, Slim Metal Alloy Current Sense Resistors, Metal Alloy Shunt Resistors, Metal Foil Current Detection Resistors, and Metal Film Current Sensing Resistors. This article aims to help you understand the advantages of our products.

What are the advantages of our Metal Alloy Current Sensing Resistors

1.Metal Alloy Current Sense Resistors

(1)Proprietary Manufacturing Process

- High-precision dimensional control

- Good mechanical properties

- High production efficiency

- Excellent electrical insulation performance

- Good heat dissipation performance

- Strong environmental adaptability

(2)Extremely Low Resistance Values

- Low power loss

- Minimal heat generation

- Minimal impact on circuit operation

- Capable of detecting large currents

(3)Very Low Inductance

- Reduced Signal Distortion

- Electromagnetic Interference (EMI) Suppression

- Improved Circuit Stability

- Adaptability to High-Frequency, High-Speed Applications

(4)Low Thermal EMF

- High current measurement accuracy

- Good circuit stability

- Wide operating temperature range

(5)Pure Alloy Metal Material

- High conductivity

- Chemically stable properties

- Strong plasticity and machinability

- Relatively low noise generated during current flow

- High precision in resistance values

(6)Environmentally Friendly And Safe

- Lead-free

- RoHS

- HALOGEN FREE

- IATF16949

- AEQ-200

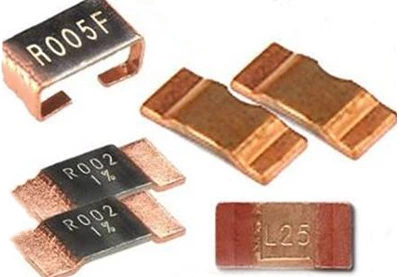

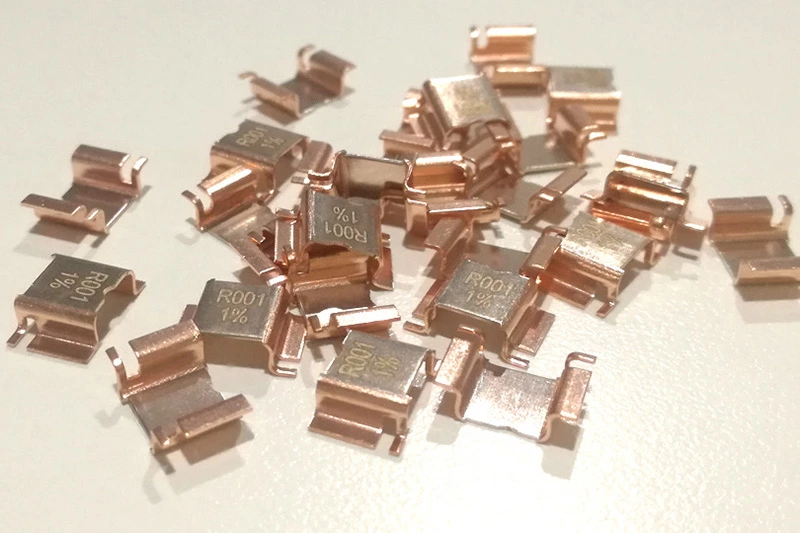

2.Slim Metal Alloy Current Sense Resistors

(1)Long Terminal Low Resistance

The long terminal design enhances the stability and reliability of the connection, while the low resistance enables more precise detection of small current changes, providing more accurate signals for measurement and helping to improve the accuracy of current measurements.

(2)Short Terminal Low-Resistance

The precision alloy current sensing resistor with short terminals and low resistance value offers advantages such as reduced parasitic inductance and distributed capacitance, improved space utilization, and enhanced mechanical stability. It can improve circuit performance, facilitate device miniaturization, and adapt to harsh environments.

(3)Small Size Ultra-thin Thickness

The precision metal alloy current sense resistor is small in size and ultra-thin in thickness, offering advantages such as space-saving, improved integration, better heat dissipation, and adaptability to special environments. It is beneficial for the miniaturization and high-performance development of electronic devices and meets the demands of specialized fields.

(4)Low TCR

- High current measurement accuracy

- Strong circuit performance stability

- Good circuit system reliability

(5)Low Inductance

- Reduced Signal Distortion

- Electromagnetic Interference (EMI) Suppression

- Improved Circuit Stability

- Adaptability to High-Frequency, High-Speed Applications

(6)Low Thermal EMF

- High current measurement accuracy

- Good circuit stability

- Wide operating temperature range

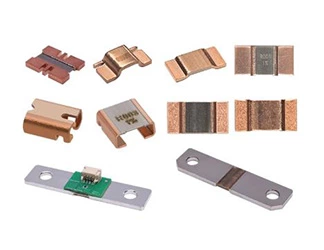

3.Metal Alloy Shunt Resistors

(1)EBW And Sampling Column Design

The design of the sampling column achieves precise current sampling by carefully planning the structure and position to ensure measurement accuracy. Electromagnetic interference is reduced by using shielding structures or materials, which enhances signal quality. Standardized interfaces are used for easy installation and connection, improving system integration and reliability. Heat dissipation is effectively managed through the use of thermal conductive materials or special heat dissipation structures, thus improving the long-term stability and service life of the shunt.

(2)High Reliability Overload Capacity And Precision

The precision alloy current sensing shunt resistors achieve stable operation under complex conditions with high reliability, reducing maintenance costs and increasing user trust. With their high overload capacity, they can withstand large current surges, enhancing system flexibility and extending equipment life. Thanks to their high precision, they enable accurate measurement and control, meeting stringent industry standards. As a result, they demonstrate significant advantages in ensuring efficient and stable system operation, reducing overall costs, and enhancing market competitiveness.

(3)Wide Temperature Range & Non-Inductive Design

The precision alloy current shunt resistors feature a wide temperature range, ensuring stable performance in complex environments such as high and low temperatures. This not only reduces the limitations of application scenarios but also minimizes measurement errors and extends service life. Additionally, the non-inductive design, with inductance less than 3 nanohenries, effectively reduces electromagnetic interference, improves electronic system compatibility, and ensures measurement accuracy in high-frequency circuits, thereby expanding the scope of applications.

(4)Low Thermoelectric Potential (< 0.5μV/°C)

The precision metal alloy current sense shunt resistors have a low thermoelectric potential (< 0.5μV/°C), which not only significantly reduces measurement errors caused by temperature changes in fields such as scientific research experiments and high-end electronic equipment manufacturing, ensuring measurement accuracy, but also provides stable signal output during temperature fluctuations or device heating, reducing the risk of system failures. At the same time, their low sensitivity to temperature changes expands the range of applications and enhances the adaptability and versatility of the equipment in various environments.

(5)Electrode Surface Treatment Optional

For example: Electrode Fully Nickel-Tin Plated. The precision alloy current sensing resistors (shunts) feature electrodes fully nickel-tin plated, which reduces contact resistance and minimizes energy loss, enhancing overall performance. The dense protective coating improves corrosion resistance and extends service life. With excellent solderability, it ensures welding quality and improves the reliability of circuit connections. It also enhances the appearance of the electrode, elevating the product's quality perception.

(6)With NTC Temperature Sensors

The precision alloy current sensing DC shunt resistors use NTC temperature sensors to monitor temperature in real time. This not only corrects measurement results and reduces errors caused by temperature fluctuations to improve measurement accuracy, providing reliable data for high-precision applications such as scientific instruments, but also enhances output stability through compensation mechanisms, reducing the risk of system failures. Additionally, it expands the environmental adaptability, broadens application scenarios, and optimizes the collaborative effect with other components, thereby improving overall system efficiency and competitiveness.

4.Metal Foil Current Detection Resistors

(1)High Precision

Metal foil resistors are manufactured using advanced processes, allowing precise control of resistance values. Their accuracy typically reaches ±0.5% or even higher, meeting the requirements of high-precision current sensing.

(2)High Stability

Metal foil resistors have a stable structure that is not easily affected by external environmental factors such as vibration or shock. They are capable of maintaining consistent resistance values and performance over time, ensuring the reliability of current sensing.

(3)Low Noise

Metal foil resistors generate very little noise during operation, which is especially important for noise-sensitive circuits or high-precision measurement systems, helping to avoid interference with measurement results.

(4)Wide Operating Temperature Range

They can operate effectively across a wide temperature range, typically from -55°C to +125°C or even broader, maintaining strong performance in various working environments.

(5)High Power Handling Capability

Metal foil resistors generally have high power handling capacity, allowing them to withstand large currents. They maintain reliable performance even under high power, with low risk of overheating, making them suitable for current sensing in high-power circuits.

(6)Excellent High-Frequency Characteristics

In high-frequency circuits, metal foil resistors perform well due to their low parasitic inductance and capacitance, minimizing the impact on high-frequency signals and enabling accurate high-frequency current detection.

5.Metal Film Current Sensing Resistors

(1)Good Temperature Stability

With a relatively low temperature coefficient—typically between ±50 ppm/°C and ±100 ppm/°C—the resistance value changes very little across different temperature environments. This effectively reduces the impact of temperature on measurement results, ensuring accurate current detection.

(2)Excellent High-Frequency Characteristics

Metal film resistors have low parasitic capacitance and inductance, allowing them to maintain good electrical performance in high-frequency circuits with minimal signal distortion. They are well-suited for high-frequency current sensing.

(3)Low Noise

The resistor material and manufacturing process result in low operational noise for metal film current sensing resistors, which helps improve signal quality—especially important in noise-sensitive circuits.

(4)Good Power Characteristics

These resistors have a certain power-handling capability, allowing them to be used in circuits with various power levels while maintaining stable performance within the rated power range.

(5)Compact Size

The thin-film structure gives them a relatively small footprint, making them easy to install on space-constrained circuit boards and supporting miniaturization and integration of electronic devices.

(6)High Cost-Effectiveness

Compared to some high-precision specialty resistors, metal film current sensing resistors have lower manufacturing costs. While meeting performance requirements, they offer good value for money and are suitable for large-scale production and application.