SRF0603P125LR

Features

- Resettable over current and over temperature protection Standard 0402mils footprint

- Fast time-to-trip

- RoHS complaint

- Low resistance

Applications

- USB peripherals including new USB 3.0 / 2.0 ports

- Li-ion / Li-Polymer battery packs

- Smart phones

- E-readers

- LCD / LED HDTV Tablet , Notebook PCs and Computer peripherals Digital cameras and video cameras

- Hard disk drives

- Game consoles

Electrical Characteristics

| Part Number | IH (A) |

IT (A) |

Vmax (V) |

Imax (A) |

Time to Trip | Pdtyp (W) |

Rmin (Ω) |

R1max (Ω) |

|

|---|---|---|---|---|---|---|---|---|---|

| (A) | (Sec.) | ||||||||

| SRF0603P035LR | 0.35 | 0.70 | 6 | 50 | 8.00 | 0.10 | 0.70 | 0.065 | 0.420 |

| SRF0603P050LR | 0.50 | 1.00 | 6 | 50 | 8.00 | 0.10 | 0.50 | 0.060 | 0.350 |

| SRF0603P075LR | 0.75 | 1.50 | 6 | 50 | 8.00 | 2.00 | 0.50 | 0.038 | 0.250 |

| SRF0603P100LR | 1.00 | 2.00 | 6 | 50 | 8.00 | 2.00 | 0.50 | 0.020 | 0.100 |

| SRF0603P110LR | 1.10 | 2.20 | 6 | 50 | 8.00 | 0.30 | 0.50 | 0.030 | 0.120 |

| SRF0603P125LR | 1.25 | 2.50 | 6 | 50 | 8.00 | 0.40 | 0.50 | 0.015 | 0.095 |

| SRF0603P150LR | 1.50 | 3.00 | 6 | 50 | 8.00 | 2.00 | 0.50 | 0.015 | 0.085 |

| SRF0603P175LR | 1.75 | 3.50 | 6 | 50 | 8.00 | 5.00 | 0.50 | 0.009 | 0.070 |

| SRF0603P200LR | 2.00 | 4.00 | 6 | 50 | 8.00 | 5.00 | 0.70 | 0.008 | 0.065 |

| SRF0603P250LR | 2.50 | 5.00 | 6 | 50 | 8.00 | 5.00 | 0.60 | 0.004 | 0.050 |

| SRF0603P260LR | 2.60 | 5.20 | 6 | 50 | 8.00 | 5.00 | 1.10 | 0.007 | 0.060 |

| SRF0603P300LR | 3.00 | 6.00 | 6 | 50 | 8.00 | 5.00 | 1.10 | 0.006 | 0.055 |

IH=Hold current: maximum current at which the device will not trip at 25℃ still air.

IT=Trip current: minimum current at which the device will always trip at 25℃ still air.

Vmax=Maximum continuous voltage device can withstand without damage at rated current

Imax=Maximum fault current device can withstand without damage at rated voltage.

Ttrip=Maximum time to trip(s) at assigned current.

Pdtyp=Typical power dissipation: typical amount of power dissipated by the device when in state air environment.

Rmin=Minimum resistance of device in initial (un-soldered) state.

R1max=Maximum resistance of device at 25℃ measured one hour after reflow.

Noted: All electrical function test is conducted after PCB mounted.

Thermal Derating Chart

Hold Current (A)

| Part Number | Ambient Operating Temperature | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| -40°C | -20°C | 0°C | 25°C | 40°C | 50°C | 60°C | 70°C | 85°C | |

| SRF0603P035LR | 0.49 | 0.46 | 0.40 | 0.35 | 0.30 | 0.26 | 0.23 | 0.19 | 0.14 |

| SRF0603P050LR | 0.73 | 0.66 | 0.58 | 0.50 | 0.43 | 0.36 | 0.32 | 0.28 | 0.22 |

| SRF0603P075LR | 1.05 | 0.98 | 0.86 | 0.75 | 0.64 | 0.56 | 0.49 | 0.41 | 0.30 |

| SRF0603P100LR | 1.40 | 1.30 | 1.15 | 1.00 | 0.85 | 0.75 | 0.65 | 0.55 | 0.40 |

| SRF0603P110LR | 1.60 | 1.40 | 1.30 | 1.10 | 1.00 | 0.85 | 0.75 | 0.65 | 0.55 |

| SRF0603P125LR | 1.82 | 1.65 | 1.44 | 1.25 | 1.06 | 0.90 | 0.80 | 0.70 | 0.56 |

| SRF0603P150LR | 2.50 | 2.25 | 2.00 | 1.50 | 1.32 | 1.15 | 1.00 | 0.85 | 0.60 |

| SRF0603P175LR | 2.50 | 2.25 | 2.00 | 1.75 | 1.50 | 1.32 | 1.15 | 1.00 | 0.85 |

| SRF0603P200LR | 2.80 | 2.60 | 2.30 | 2.00 | 1.70 | 1.50 | 1.30 | 1.10 | 0.80 |

| SRF0603P250LR | 4.30 | 3.70 | 3.15 | 2.50 | 2.00 | 1.85 | 1.55 | 1.10 | 0.90 |

| SRF0603P260LR | 4.40 | 3.80 | 3.25 | 2.60 | 2.10 | 1.95 | 1.65 | 1.20 | 1.00 |

| SRF0603P300LR | 4.40 | 3.90 | 3.45 | 3.00 | 2.55 | 2.10 | 1.95 | 1.65 | 1.20 |

Notes: The temperature rerating data is for reference only. Please contact PROSEMI technical support for detail temperature rerating information.

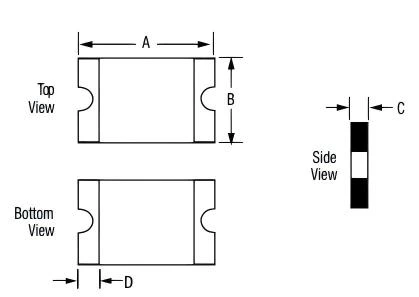

Dimensions (mm)

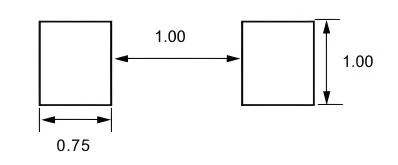

Recommended Pad Layout (mm)

| Part Number | Marking | A | B | C | D | |||

|---|---|---|---|---|---|---|---|---|

| Min. | Max. | Min. | Max. | Min. | Max. | Min. | ||

| SRF0603P035LR | C | 1.45 | 1.85 | 0.65 | 1.05 | 0.35 | 0.75 | 0.20 |

| SRF0603P050LR | F | 1.45 | 1.85 | 0.65 | 1.05 | 0.35 | 0.75 | 0.20 |

| SRF0603P075LR | H | 1.45 | 1.85 | 0.65 | 1.05 | 0.35 | 0.75 | 0.20 |

| SRF0603P100LR | I | 1.45 | 1.85 | 0.65 | 1.05 | 0.35 | 0.75 | 0.20 |

| SRF0603P110LR | I | 1.45 | 1.85 | 0.65 | 1.05 | 0.35 | 0.75 | 0.20 |

| SRF0603P125LR | J | 1.45 | 1.85 | 0.65 | 1.05 | 0.35 | 0.75 | 0.20 |

| SRF0603P150LR | L | 1.45 | 1.85 | 0.65 | 1.05 | 0.35 | 0.75 | 0.20 |

| SRF0603P175LR | O | 1.45 | 1.85 | 0.65 | 1.05 | 0.35 | 0.75 | 0.20 |

| SRF0603P200LR | S | 1.45 | 1.85 | 0.65 | 1.05 | 0.35 | 0.75 | 0.20 |

| SRF0603P250LR | T | 1.45 | 1.85 | 0.65 | 1.05 | 0.35 | 0.75 | 0.20 |

| SRF0603P260LR | Z | 1.45 | 1.85 | 0.65 | 1.05 | 0.50 | 0.90 | 0.20 |

| SRF0603P300LR | Z | 1.45 | 1.85 | 0.65 | 1.05 | 0.50 | 0.90 | 0.20 |

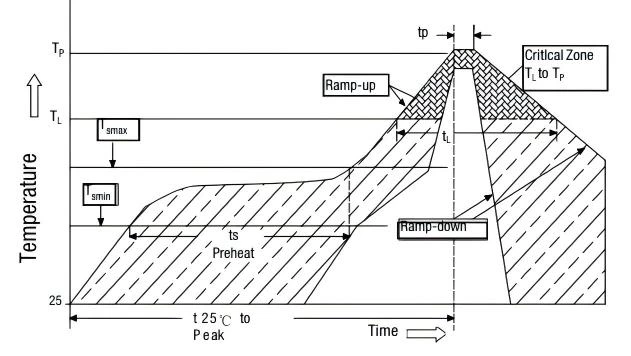

Solder Reflow Conditions

| Reflow Profile | Lead free |

|---|---|

| Heating rate from Tsmax to Tp | Max. 3℃/second |

| Pre-heat: Tsmin Tsmax Tsmin to Tsmax |

150℃ 200℃ 60~180 seconds |

| Soldering time: Temperature (TL) Time (tL) |

>217℃ 60~150 seconds |

| Peak temperature (Tp) | 260℃ |

| Time at Peak temperature ±5℃ (tp) | 20~40 seconds |

| Cooling rate | Max. 6℃/second |

| Time from 25℃ to Peak Temperature | 8 minutes max |

Cautions for Reflow:

1. Recommended reflow methods: IR, hot air oven, nitrogen oven;

2. The printed solder thickness is not over 0.25mm,Excess solder may cause a short circuit, especially during hand soldering;

3. If reflow temperatures exceed the recommended profile, devices may not meet the performance requirements;

4. Device can not be wave soldered. Please contact Prosemi for hand soldering and dip soldering recommendations;

5. Device can’t contact solvent;

Note:All temperature in top chart is measured on the surface of devices.

Packaging Options

| I hold(A) | Quantity |

|---|---|

| 0.35~3.00 | 5,000pcs |

Reel packaging per EIA-481-1 standard