ALMA2725 Current Sensing Resistors

Application

- Entertainment product .

- Power supply

- Measuring instrument

- Industrial product

- Battery management system

Features

- Low Resistance / Low TCR

- Excellent long term stability

- RoHs compliant and halogen free.

- Lead free.

- AEC-Q200 qualified available

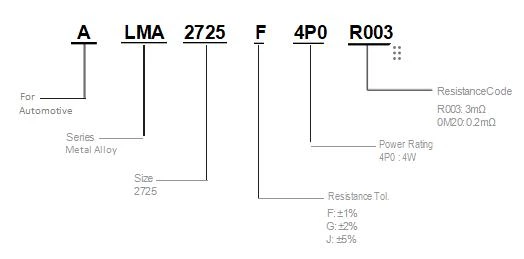

Part Numbering System

| Type | Rating Power at 70°C | T.C.R. (ppm/°C) | Resistance Range (mΩ) 1.0%(F) 2.0%(G) 5.0%(J) |

Material | Operating Temperature (°C) |

|---|---|---|---|---|---|

| ALMA2725 | 4W | ±100 | 0.2 | FeCrAl, MnCuSn, MnCu | -55°C~170°C |

| ±50 | 0.25~3 |

construction

Unit: mm

| Type | Resistance (mΩ) | L | W | H | T1 | T2 |

|---|---|---|---|---|---|---|

| ALMA2725 | 0.2 | 6.9 ±0.254 | 6.35 ±0.254 | 1.10 ±0.254 | 1.2 ±0.254 | 2.15 ±0.254 |

| 0.25 | 0.95 ±0.254 | 2.287 ±0.254 | ||||

| 0.3 | 1.975 ±0.254 | |||||

| 0.35 | 1.71 ±0.254 | |||||

| 0.4 | 1.44 ±0.254 | |||||

| 0.5 | 0.85 ±0.254 | 2.08 ±0.254 | ||||

| 0.6 | 1.78 ±0.254 | |||||

| 0.8 | 1.30 ±0.254 | |||||

| 1.0 | 6.8 ±0.254 | 0.65 ±0.254 | 1.15 ±0.254 | 1.8 ±0.254 | ||

| 1.5~1.6 | 1.5 ±0.254 | |||||

| 2.0~3.0 | 0.55 ±0.254 |

Recommended land pattern

Unit: mm

| Type | Resistance (mΩ) | a | b | i |

|---|---|---|---|---|

| ALMA2725 | 0.2~0.35 | 2.9 | 6.7 | 1.28 |

| 0.4~0.8 | 3.25 | 6.85 | 1.7 | |

| 1~3 | 2.75 | 6.85 | 2.7 |

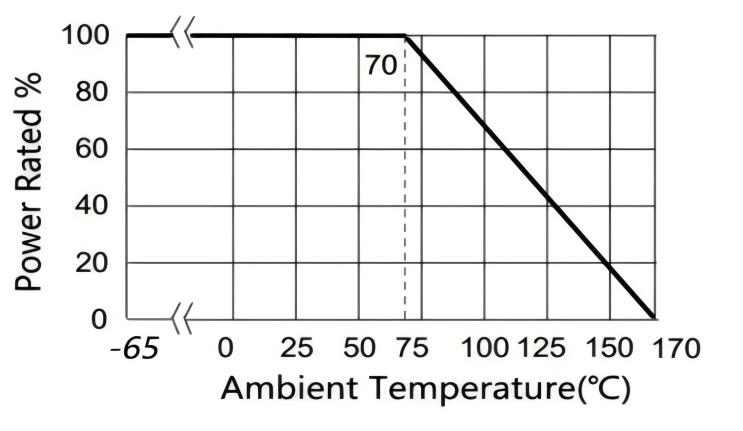

Power Derating Curve

For resistors operated in ambient temperatures 70°C, power ratingshall bederated inaccording with the curve above.

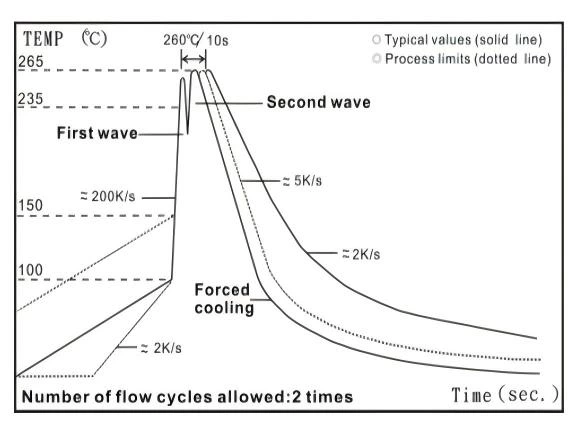

Wave solder Temperature condition

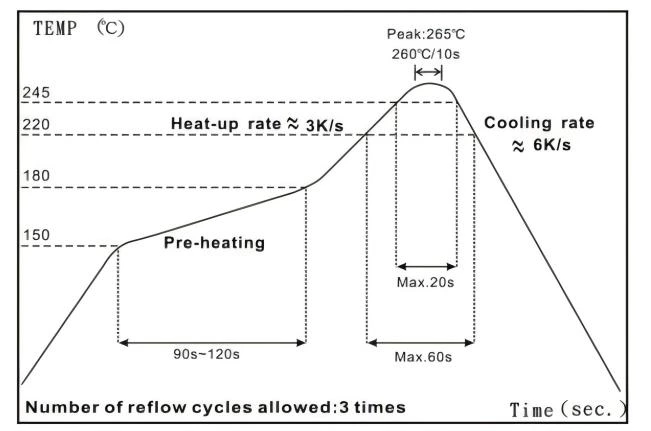

Solder Reflow Temperature Condition

Soldering Iron: temperature 350℃±10℃ , dwell timeshall be less than 3 sec.

Product Characteristics

| Item | Test Condition/Methods | Limited |

|---|---|---|

| Temperature Coefficient of Resistance | At 25℃ / +150℃, 25℃ is the reference temperature. | Refer to Spec |

| Short Time Overload | 4 X rated power for 5s | ±0.5% |

| Resistance to Soldering Heat |

260℃± 5℃ time:10sec

|

±0.5% |

| Temperature Cycling | 1000 Cycles (-55°C to +155°C). Measurement at 24 ±4 hours after test conclusion. 30 min maximum dwell time at each temperature extreme. | ±0.5% |

| High Temperature Storage | 1000 hours at 170℃, No power | ±1% |

| Bias Humidity | 1,000 hours; 85°C / 85% RH, 10% of operating power. Measurement at 24 ±4 hours after test conclusion. | ±0.5% |

| Load Life (Endurance) | 70 ±2℃, RCWV or Max. working voltage whichever is less for 1000 hrs with 1.5 hrs "ON" and 0.5 hrs "OFF". | ±1% |

| Solderability |

245℃±5℃ , 3s

|

95% Coverage Minimum |

| Dielectric Withstanding Voltage | Applied 500VAC for 1 minute. | No short or burned appearance. |

| Core Body Strength | Central part pressurizing force: 5N, 10 seconds | No broken |

| Terminal Strength (SMD) | Pressurizing force 17.7N for 60 seconds | No broken |

| Bending Strength | Bending once 2mm for 10 seconds | ±0.5% |

| Moisture Resistance | T = 24 hours / Cycle, 10 Cycles. Steps 7a & 7b not required. Unpowered. |

±0.5% |

*Note: This test is a destructive experiment. The top protective layer is prone to damage and peculiar smell during, in the 50mR~100mR resistance test. The resistance change rate can meets the specifications.

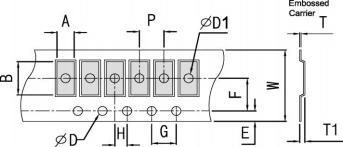

Tapping & Package

Unit: mm

| Type | Resistance (mΩ) | W ±0.3 | P +0.1 | E ±0.1 | F ±0.1 | D | D1 ±0.1 | G ±0.1 | H ±0.1 | A ±0.1 | B ±0.1 | T1 ±0.1 | T ±0.05 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2725 | 0.2~0.8 | 12.0 | 8.0 | 1.75 | 5.5 | 1.5 +0.1/-0 | 1.55 | 4.0 | 2.0 | 6.81 | 7.16 | 1.3 | 0.25 |

| 1~3 | 1.05 |

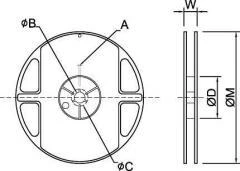

Reel Specification

Unit: mm

| Reel Type / Tape | A | B | C | D | W | M |

|---|---|---|---|---|---|---|

| 7” reel for 12 mm embossed | 2.5 ±0.5 | 13.5 ±0.5 | 17.7 ±0.5 | 60 ±0.5 | 16.2 ±0.5 | 178 ±1 |

| 7” reel for 24 mm embossed | 2.0 ±0.5 | 13.2 ±0.5 | 24.4 ±2.0 |

Packing

| Type | Quantity (pcs) |

|---|---|

| 2725 (R ≥ 1) | 2000 |

| 2725 (0.8 ≥ R ≥ 0.2) | 1000 |

Storage Temperature

- Storage time at the environment temp: 25±5℃& humidity: 60±20% is valid for one year from the date of delivery