ALMJ12 Current Sense Resistor

Description

- Proprietary processing technique produces extremely low resistance values

- Very low inductance

- Low thermal EMF

- Metallic Material

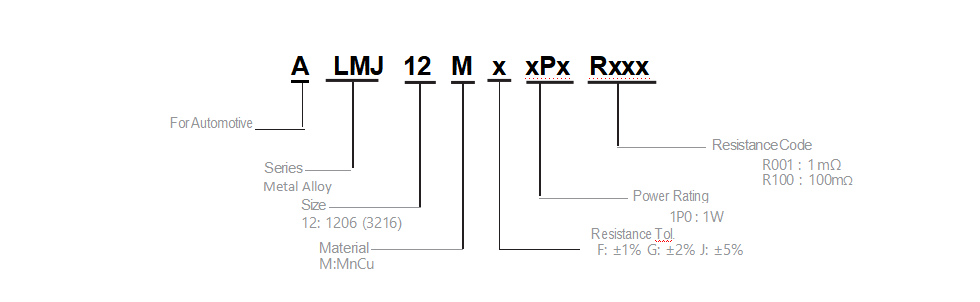

Part Numbering System

| Parameter | Standard |

|---|---|

| Power Rating | 0.5 & 1W |

| Resistance Value | 1~200 mΩ |

| Operating Temperature Range | -55 to +170°C |

| Component Temperature Coefficient (TCR) | ±50 ppm/°C |

| Maximum Working Voltage (V) | (P × R)1/2 |

| Rating Current (A) | (P / R)1/2 |

P=Power Rating; R=Resistance Value

Standard Electrical Specifications

| Type | Rating Power at 70℃ | T.C.R. (ppm/℃) | Resistance Range (mΩ) 1.0%(F) 2.0%(G) 5.0%(J) | Material | Electrode | Operating Temperature (℃) |

|---|---|---|---|---|---|---|

| ALMJ12 | 1W | ±50 | 1~100 | R001~R100: MnCu | R001: (wide) | -55~+170°C |

| R002~R100: (narrow) | ||||||

| 0.5W | ±50 | 101~200 | R101~R200: MnCu | R101~R200: (narrow) |

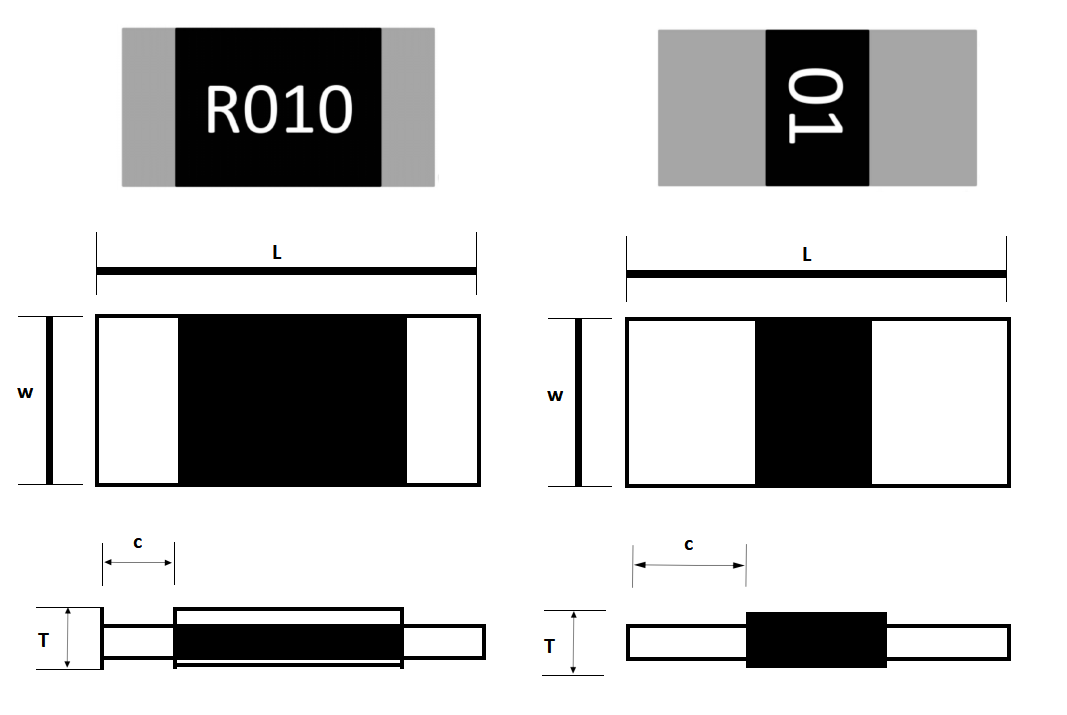

Dimensions

Unit: mm

| Type | Resistance Range (mΩ) | L | W | C | T |

|---|---|---|---|---|---|

| ALMJ12 | 1 | 3.2 ±0.2 | 1.6 ±0.2 | 1.2 ±0.2 (wide) | 0.7 ±0.15 |

| 2~200 | 3.2 ±0.2 | 1.6 ±0.2 | 0.5 ±0.2 | 0.7 ±0.15 |

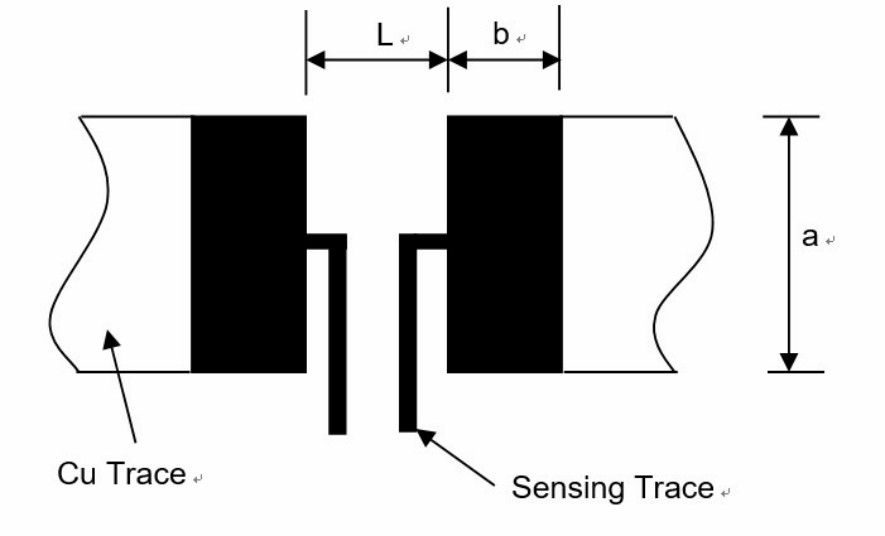

Recommended land pattern

Unit:mm

| Resistance Range (mΩ) | a | b | L |

|---|---|---|---|

| 1 | 1.8 ±0.1 | 2.3 ±0.1 | 1.0 ±0.1 |

| 2~200 | 1.8 ±0.1 | 1.7 ±0.1 | 1.6 ±0.1 |

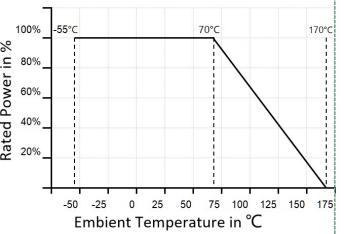

Derating Curve

For resistors operated in ambient temperatures 70°C, power ratingshall bederated inaccording with the curve below

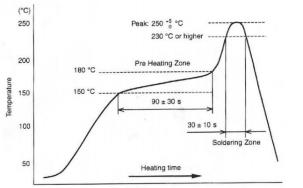

IR Reflow-Soldering Profile

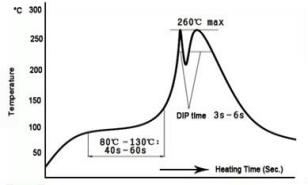

Wave- Soldering Profile

Product Characteristics

| Item | Test Condition/Methods | Limited | Standard |

|---|---|---|---|

| Resistance | Measuring resistance value at room temperature 25℃ ±5℃ | Refer to Spec | IEC60115-1 4.5 |

| Temperature Coefficient of Resistance | TCR = (R-R0)/R0(T2-T1) × 10⁶ R0: resistance at room temperature R: resistance at 125℃ T1: room temperature T2: 125℃ |

Refer to Spec | MIL-STD-202 Method 304 |

| Short Time Overload | 5 × Rated power for 5 seconds | ≤±0.5% | MIL-STD-202 Method 210 |

| Resistance to Soldering Heat | 260℃ ±5℃, 10 sec ±1 sec | ≤±0.5% | MIL-STD-202 Method 210 |

| Temperature Cycling | -55℃ (30min) / +125℃ (30min), 1000 cycles | ≤±0.5% | MIL-STD-202 Method 107G |

| Low Temperature Storage | -55℃ for 1000 hours, No power | ≤±0.5% | MIL-STD-26E |

| High Temperature Storage | 125℃ for 1000 hours, No power | ≤±1% | IEC60115-1 4.25 |

| Bias Humidity | +85℃, 85% RH, 10% bias, 1.5h "ON" / 0.5h "OFF", 1000 hours | ≤±0.5% | MIL-STD-202 Method 103 |

| Joint Strength of Solder | Soldered on bending test plate, load applied at center, measure resistance change | ≤±0.5% | JIS-C5201 |

| Solderability | Solder at 245℃ ±5℃, dipping time 3±1 sec, solder coverage ≥95% | 95% Coverage | IEC60115-1 4.17 |

| Load Life | 1000 hours at 70℃, 1.5h "ON", 0.5h "OFF" | ≤±1% | JIS-C5201 |

| Operational Life | 125℃ ±3℃, 1000 hours, at rated power | ≤±0.5% | MIL-STD-202 Method 108 |

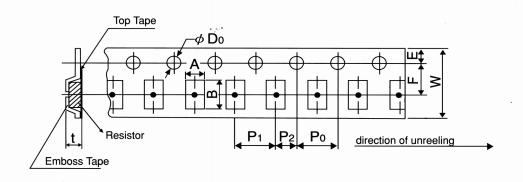

Tapping & Package

Unit: mm

| Type | Pack | A ±0.2 | B ±0.2 | D0 +0.5/-0 | E ±0.1 | F ±0.05 | P0 ±0.1 | P1 ±0.1 | P2 ±0.1 | W ±0.2 | T ±0.15 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1206 | Paper | 2.00 | 3.60 | 1.50 | 1.75 | 3.50 | 4.00 | 4.00 | 2.00 | 8.00 | 0.81 |

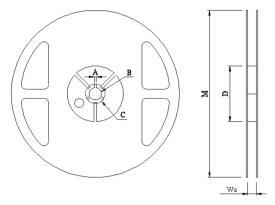

Reel Specification

Unit: mm

| Type | A (mm) | B (mm) | C (mm) | D (mm) | M (mm) | W (mm) |

|---|---|---|---|---|---|---|

| 1206 | 2.00 ±0.5 | 13.5 ±0.5 | 21.00 ±0.5 | 60.00 ±1.0 | 178.00 ±2.0 | 9.00 ±0.5 |

Packaging

Quantity: 5, 000pcs

8mm wide tape on 178mm(7 inch)

diameter reel -specification EIA

Standard 481.