ALMJ12 Current Sense Resistor

Description

- Proprietary processing technique produces extremely low resistance values

- Very low inductance

- Low thermal EMF

- Metallic Material

- ACE-Q200 qualified Current Sensing Resistor

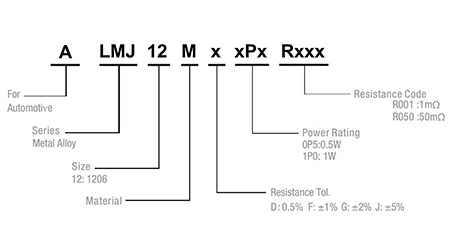

Part Numbering System

| Parameter | Standard |

|---|---|

| Power Rating | 0.5 & 1W |

| Resistance Value | 1~200 mΩ |

| Operating Temperature Range | -55 to +170°C |

| Component Temperature Coefficient (TCR) | ±50 ppm/°C |

| Maximum Working Voltage (V) | (P × R)1/2 |

| Rating Current (A) | (P / R)1/2 |

P=Power Rating; R=Resistance Value

Standard Electrical Specifications

| Type | Rating Power at 70℃ |

T.C.R. (ppm/℃) |

Resistance Range (mΩ) 0.5%(D),1.0%(F) 2.0%(G),5.0%(J) |

Material | Electrode | Operating Temperature (℃) |

|---|---|---|---|---|---|---|

| ALMJ12 | 1W | ±150 | 1 | MnCu | Wide | -55~+170°C |

| ±380 | 1.5 | Narrow | ||||

| ±100 | 2&2.5 | |||||

| ±50 | 3~100 | |||||

| 0.5W | ±50 | 101~200 | Karma | Narrow |

Resistance Values of the 1206 Series, 1W Resistors

| Standard Resistance Values ( Ω ) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 ohm | 0.001 ohm | 0.002 ohm | 0.003 ohm | 0.005 ohm | 0.01 ohm | 0.015 ohm | 0.02 ohm | 0.025 ohm | 0.03 ohm | 0.04 ohm | 0.05 ohm | 0.1 ohm |

| R000 | R001 | R002 | R003 | R005 | R010 | R015 | R020 | R025 | R030 | R040 | R050 | R100 |

| Manufacturable Resistance Values ( Ω ) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.0015 ohm | 0.0025 ohm | 0.004 ohm | 0.0048 ohm | 0.006 ohm | 0.007 ohm | 0.008 ohm | 0.009 ohm | 0.011 ohm | 0.012 ohm | 0.013 ohm | 0.014 ohm | 0.018 ohm |

| R0015 | R0025 | R004 | R0048 | R006 | R007 | R008 | R009 | R011 | R012 | R013 | R014 | R018 |

| 0.022 ohm | 0.024 ohm | 0.027 ohm | 0.033 ohm | 0.035 ohm | 0.039 ohm | 0.045 ohm | 0.047 ohm | 0.06 ohm | 0.068 ohm | 0.07 ohm | 0.075 ohm | 0.08 ohm |

| R022 | R024 | R027 | R033 | R035 | R039 | R045 | R047 | R060 | R068 | R070 | R075 | R080 |

| 0.082 ohm | 0.09 ohm | —— | ||||||||||

| R082 | R090 | |||||||||||

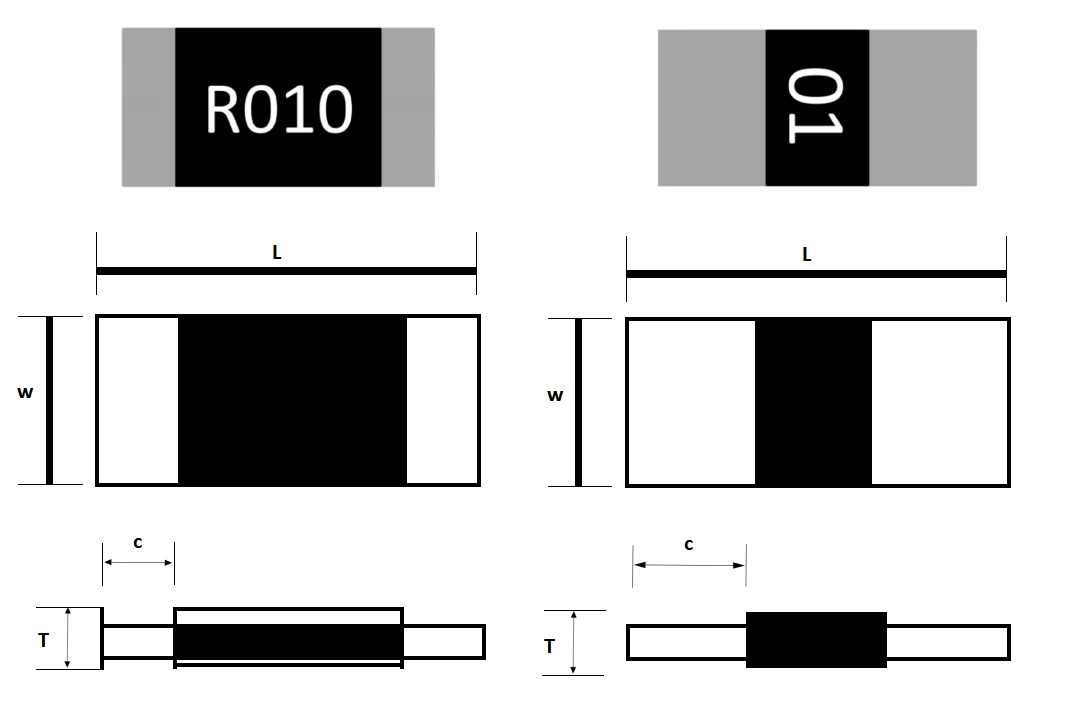

Dimensions

Unit: mm

| Type | Resistance Range (mΩ) |

L | W | C | T |

|---|---|---|---|---|---|

| ALMJ12 | 1 | 3.2 ±0.2 | 1.6 ±0.2 | 1.2 ±0.2 (wide) | 0.7 ±0.15 |

| 2~200 | 3.2 ±0.2 | 1.6 ±0.2 | 0.5 ±0.2 (narrow) | 0.7 ±0.15 |

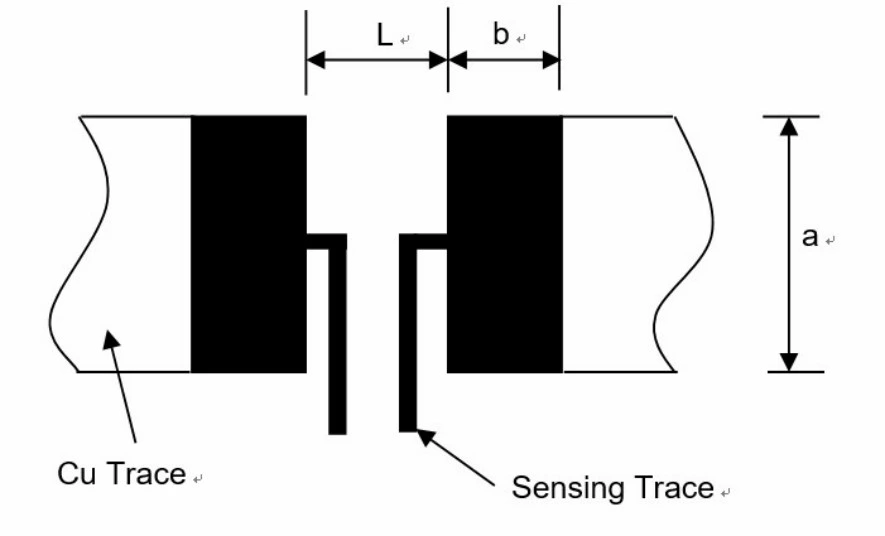

Recommended land pattern

Unit:mm

| Resistance Range (mΩ) |

a | b | L |

|---|---|---|---|

| 1 | 1.8 ±0.1 | 2.3 ±0.1 | 1.0 ±0.1 |

| 2~200 | 1.8 ±0.1 | 1.7 ±0.1 | 1.6 ±0.1 |

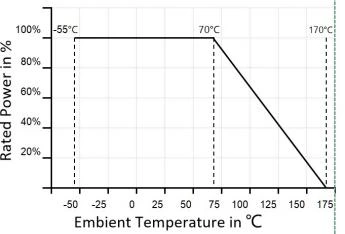

Derating Curve

For resistors operated in ambient temperatures 70°C, power rating shall be derated inaccording with the curve above.

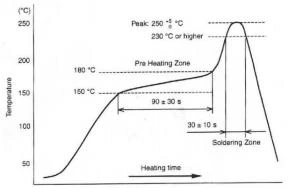

IR Reflow-Soldering Profile

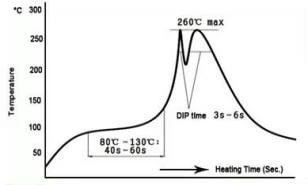

Wave- Soldering Profile

Product Characteristics

| Item | Test Condition/ Methods | Limited | Standard |

|---|---|---|---|

| Resistance | Measuring resistance value at room temperature 25℃ ±5℃ | Refer to Spec | IEC60115-1 4.5 |

| Temperature Coefficient of Resistance | TCR = (R-R0)/R0(T2-T1) × 10⁶ R0: resistance at room temperature R: resistance at 125℃ T1: room temperature T2: Temperature at 125℃ |

Refer to Spec | MIL-STD-202 Method 304 |

| Short Time Overload | 5 × Rated power for 5 seconds | ≤±0.5% | MIL-STD-202 Method 210 |

| Resistance to Soldering Heat | 260℃ ±5℃ time: 10sec± 1sec | ≤±0.5% | MIL-STD-202 Method 210 |

| Temperature Cycling | -55℃ (30min) / +150℃ (15min), 1000 cycles | ≤±0.5% | MIL-STD-202 Method 107G |

| Low Temperature Storage | -55℃ for 96 hours, No power | ≤±0.5% | MIL-STD-26E |

| High Temperature Storage | 170℃ for 1000 hours, No power | ≤±1% | IEC6011501-4.25 |

| Bias Humidity | +85℃, 85% RH, 10% bias 1000 hours | ≤±0.5% | MIL-STD-202 Method 103 |

| Terminal bending | It is soldered into a bendable test board and placedon a bending tester. A force of 2.5 kg is applied to the center of the test board to press it down by 2 mm. The resistance change rate is measured after maintaining the load for 60 seconds. | ≤±0.5% | JIS-C5201 |

| Solderability | Temperature of Solder: 245℃ ±5℃ Dipping time 3±1s | Solder coverage over 95% | IEC60115-1 4.17 |

| Load Life | 1000 h at 70℃, 1.5h "ON", 0.5h "OFF" | ≤±1% | JIS-C5201 |

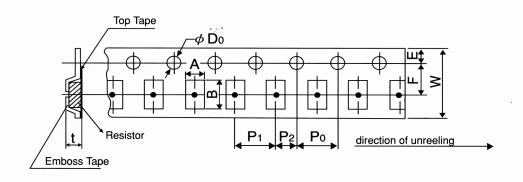

Tapping & Package

Unit: mm

| Type | Pack | A ±0.2 |

B ±0.2 |

D0 ±0.05/-0 |

E ±0.1 |

F ±0.05 |

P0 ±0.1 |

P1 ±0.1 |

P2 ±0.1 |

W ±0.2 |

T ±0.15 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1206 | Paper | 2.00 | 3.60 | 1.50 | 1.75 | 3.50 | 4.00 | 4.00 | 2.00 | 8.00 | 0.81 |

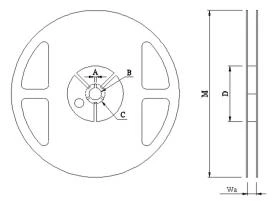

Reel Specification

Unit: mm

| Type | A | B | C | D | M | W |

|---|---|---|---|---|---|---|

| 1206 | 2.00 ±0.5 | 13.5 ±0.5 | 21.00 ±0.5 | 60.00 ±1.0 | 178.00 ±2.0 | 9.00 ±0.5 |

Packaging

Quantity: 5, 000pcs

8mm wide tape on 178mm(7 inch)

diameter reel -specification EIA

Standard 481.