LMJ12 Current Sense Resistor

Description

- Proprietary processing technique produces extremely low resistance values

- Very low inductance

- Low thermal EMF

- Metallic Material

Part Numbering System

| Parameter | Standard |

|---|---|

| Power Rating | 0.5W & 1W |

| Resistance Value | 1mΩ ~ 200mΩ |

| Operating Temperature Range | -55 to + 170°C |

| Component Temperature Coefficient (TCR) | ± 50ppm/°C & 380ppm/°C |

| Maximum Working Voltage (V) | (P×R)1/2 |

| Rating Current (A) | (P/R)1/2 |

P=Power Rating; R=Resistance Value

Standard Electrical Specifications

| Type | Rating Power at 70℃ |

T.C.R. (ppm/℃) |

Resistance Range(mΩ) 0.5%(D),1.0%( F) 2.0%(G),5.0%(J) |

Meterial | Electrode | Operating Temperature(℃) |

|---|---|---|---|---|---|---|

| LMJ12 | 1W | ±380 | 1~100 | R001~R100: MnCu | R001 | -55~+170°C |

| ±50 | R001: (S) | |||||

| R002~R100 | ||||||

| 0.5W | ±50 | 101~200 | R101~R200:MnCu | R101~R200 |

Resistance Values of the 1206 Series, 1W Resistors

| Standard Resistance Values ( Ω ) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 ohm | 0.001 ohm | 0.002 ohm | 0.003 ohm | 0.005 ohm | 0.01 ohm | 0.015 ohm | 0.02 ohm | 0.025 ohm | 0.03 ohm | 0.04 ohm | 0.05 ohm | 0.1 ohm |

| R000 | R001 | R002 | R003 | R005 | R010 | R015 | R020 | R025 | R030 | R040 | R050 | R100 |

| Manufacturable Resistance Values ( Ω ) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.0015 ohm | 0.0025 ohm | 0.004 ohm | 0.0048 ohm | 0.006 ohm | 0.007 ohm | 0.008 ohm | 0.009 ohm | 0.011 ohm | 0.012 ohm | 0.013 ohm | 0.014 ohm | 0.018 ohm |

| R0015 | R0025 | R004 | R0048 | R006 | R007 | R008 | R009 | R011 | R012 | R013 | R014 | R018 |

| 0.022 ohm | 0.024 ohm | 0.027 ohm | 0.033 ohm | 0.035 ohm | 0.039 ohm | 0.045 ohm | 0.047 ohm | 0.06 ohm | 0.068 ohm | 0.07 ohm | 0.075 ohm | 0.08 ohm |

| R022 | R024 | R027 | R033 | R035 | R039 | R045 | R047 | R060 | R068 | R070 | R075 | R080 |

| 0.082 ohm | 0.09 ohm | —— | ||||||||||

| R082 | R090 | |||||||||||

Dimensions

Unit: Millimeters

| Type | Resistance Range (mΩ) |

L | W | C | T |

|---|---|---|---|---|---|

| LMJ 12 | 1 (S) | 3.2 ±0.2 | 1.6 ±0.2 | 1.2 ±0.2 | 0.7± 0.15 |

| 1~200 | 3.2 ±0.2 | 1.6 ±0.2 | 0.5±0.2 | 0.7± 0.15 |

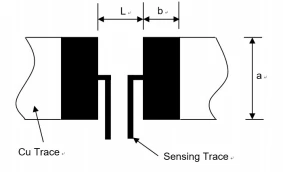

Recommended land pattern

Unit: Millimeters

| Resistance Range ( mΩ ) | a | b | L |

|---|---|---|---|

| 1 (S) | 1.8±0.1 | 2.3±0.1 | 1.0±0.1 |

| 1~200 | 1.8±0.1 | 1.7±0.1 | 1.6±0.1 |

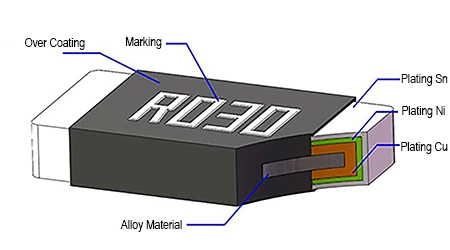

Product structure diagram

| Part | Figure Name | Material | Thickness (Reference value) |

|---|---|---|---|

| Resistive Element | Allooy Material | MnCu | 150±8μm |

| Protective Coating | Over Coating | SiO2 & Epoxy | 700±150μm |

| Marking | Marking | Epoxy | 5±3μm |

| Terminal Electrode | Plating Cu | Cu | 120±20μm |

| Terminal Electrode | Plating Ni | Ni | 5±2μm |

| Terminal Electrode | Plating Sn | Sn | 8±3μm |

Product Characteristics

| Item | Test condition/ Methods | Limited | Standard |

|---|---|---|---|

| Resistance | Measuring resistance value at room temperature 25℃±5℃ |

Refer to Spec | IEC60115-1 4.5 |

| Temperature coefficient of resistance | TCR =(R-R0)/R0(T2-T1)X 106 R0 : resistance of room temperature R: resistance of 125℃ T1: Room temperature T2: Temperature at 125℃ |

Refer to Spec | MIL-STD-202 Method 304 |

| Short time Overload | 5×Rated power for 5 seconds | ≤±0.5% | MIL-STD-202 Method 210 |

| Resistance to Soldering Heat | 260℃± 5℃ time: 10sec± 1sec | ≤±0.5% | MIL-STD-202| Method 210 |

| Temperature Cycling | -55℃ (30min)/+125℃(30min), 1000 cycles | ≤±0.5% | MIL-STD-202 Method107G |

| Low temperature Storage | -55℃ for 1000hours, No power | ≤±0.5% | MIL-STD-26E |

| High Temperature Storage | 125℃ for 1000hours, No power | ≤±1% | IEC6011501-4.25 |

| Bias Humidity | +85℃, 85% RH, 10%bias, 1.5 h "ON", 0.5 h "OFF" , 1000hours | ≤±0.5% | MIL-STD-202 Method103 |

| Joint Strength of Solder | Soldered on the bending test plate, put on the bending testing machine, pressed under force in the center of the test plate, measure its resistance variance rate under load |

≤±0.5% | JIS-C5201 |

| Solderability | Temperature of Solder :245±5℃ Dipping time:3±1s |

Solder coverage over 95% |

IEC60115-1 4.17 |

| Load life | 1000 h at 70 °C , 1.5 h "ON", 0.5 h "OFF" | ≤±1% | JIS-C5201 |

| Operational life | 125℃± 3℃, 1000 hours, at rated power | ≤±0.5% | MIL-STD-202 Method 108 |

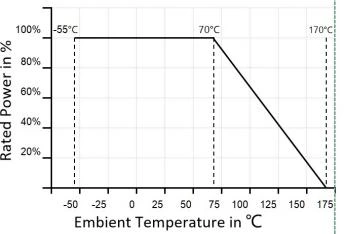

Derating Curve

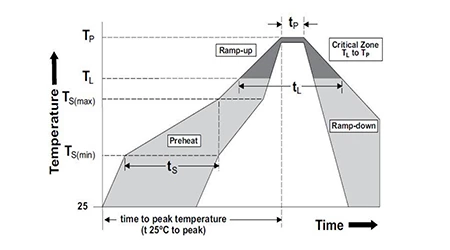

Recommended Solder Curve

| Reflow Condition | Pb - Free assembly | |

|---|---|---|

| Pre heat | -Temperature Min (Ts(min)) | 150℃ |

| -Temperature Min (Ts(min)) | 200℃ | |

| -Time (Min to Max)(ts) | 60 - 120secs | |

| Average ramp up rate (Liqudus Temp(TL) to peak | 5℃/second max | |

| TS(max)to TL - Ramp-up Rate | 5℃/second max | |

| Reflow | -Temperature (TL) (Liquidus) | 217℃ |

| -Time(tL) | 60 - 150secs | |

| Peak Temperature (TP) | 260℃ | |

| Time within 5℃ of actual peak Temperature (tp) | 20 - 40seconds | |

| Ramp-down Rate | 5℃/second max | |

| Time 25℃ to peak Temperature (TP) | 8 minutes Max. | |

| Wave Soldering | 260℃, 10 seconds max. | |

| Hand Soldering | 350℃, 5 seconds max. | |

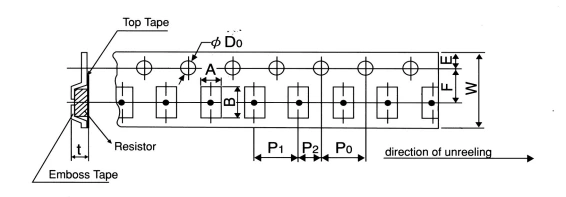

Tapping & Package

| Type | Pack | A ±0.2 |

B ±0.2 |

D0 0.05+/-0 |

E ±0.1 |

F ±0.05 |

P0 ±0.1 |

P1 ±0.1 |

P2 ±0.1 |

W ±0.2 |

T ±0.15 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1206 | Paper | 2.00 | 3.60 | 1.50 | 1.75 | 3.50 | 4.00 | 4.00 | 2.00 | 8.00 | 0.81 |

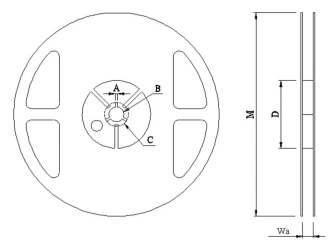

Reel Specification

| Type | A | B | C | D | M | W |

|---|---|---|---|---|---|---|

| 1206 | 2.00±0.5 | 13.5±0.5 | 21.00±0.5 | 60.00±1.0 | 178.00±2.0 | 9.00±0.5 |

Packaging

Quantity: 5, 000pcs

8mm wide tape on 178mm(7 inch)

diameter reel -specification EIA Standard 481.