LMJ25 Current Sense Resistor

Description

- Proprietary processing technique produces extremely low resistance values

- Very low inductance

- Low thermal EMF

- Metallic Material

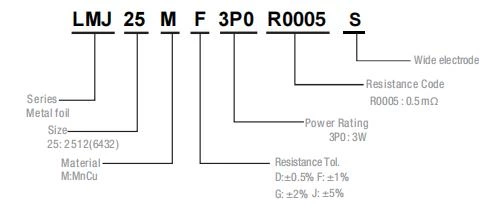

Part Numbering System

|

Parameter

|

Standard

|

|

Power Rating

|

3W

|

|

Resistance Value

|

0.5mΩ

|

|

Operating Temperature Range

|

-55 to +170°C

|

|

Component Temperature Coefficient (TCR)

|

100 ppm/°C

|

|

Maximum Working Voltage (V)

|

(P x R)1/2

|

Standard Electrical Specifications

|

Type

|

Rating

Power at

70℃

|

T.C.R.

(ppm/℃)

|

Resistance Range(mΩ)

±0.5%(D)

±1.0%(F)

±2.0%(G)

±5.0%(J

|

Meterial

|

Electrode

|

Operating

Temperature(℃)

|

|---|---|---|---|---|---|---|

|

LMJ25

|

3W

|

100

|

0.5

|

MnCu

|

Wide

|

-55~+170°C

|

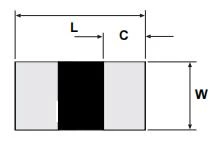

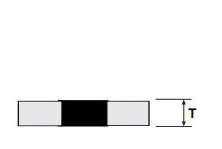

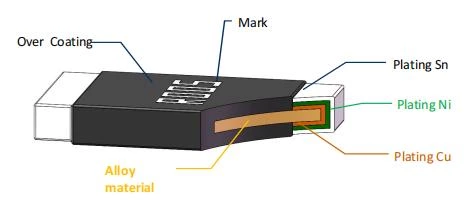

Construction

Unit: Millimeters

| Style | Resistance (mΩ) | L | W | C | T | Material |

|---|---|---|---|---|---|---|

| LMJ25 | 0.5 | 6.4 ± 0.2 | 3.2 ± 0.2 | 2.5 ± 0.2 | 0.9 ± 0.2 | MnCu |

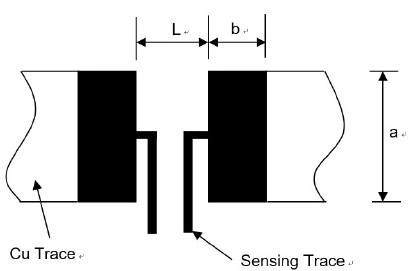

Recommended land pattern

Unit: Millimeters

|

Resistance

Range (mΩ )

|

a | b | L |

|---|---|---|---|

| 0.5 |

4.0±0.1

|

3.1±0.1

|

1.3±0.1

|

Product structure diagram

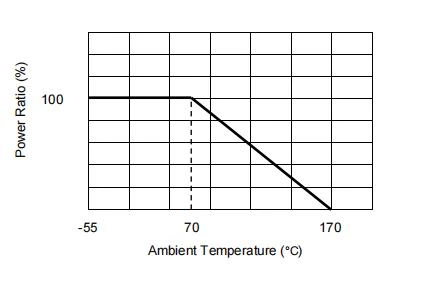

Power Derating Curve

For resistors operated in ambient temperatures 70°C, power rating shall be derated inaccording

with the curve below:

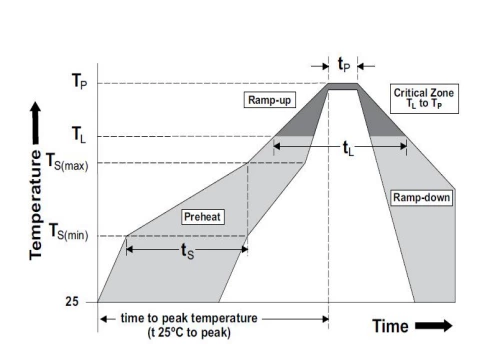

Recommended Solder Curve

| Reflow Condition | Pb-Free assembly | |

|---|---|---|

| Pre heat | -Temperature Min(Ts(min)) | 150℃ |

| -Temperature Max(Ts(max)) | 200℃ | |

| -Time(Min to Max)(ts) | 60-120 secs | |

| Average rampup rate (Llquldus Temp(TL)to peak |

5℃/second max | |

| TS(max)to TL-Ramp-up Rate | 5℃/second max | |

| Reflow | -Temperature(TL)(Liquidus) | 217℃ |

| -Temperature(tL) | 60-150 seconds | |

| Peak Temperature(TP) | 260℃ | |

| Time within 5℃of actual peak Temperature(tp) | 20-40 seconds | |

| Ramp-down Rate | 5℃/second max | |

| Time 25C to peak Temperature(TP) | 8 minutes Max. | |

| Wave Soldering | 260℃,10 seconds max | |

| Hand Soldering | 350℃,5 seconds max. | |

Product Characteristics

| Item | Test condition/Methods | Limited | Standard |

|---|---|---|---|

| Resistance | Measuring resistance value at room temperature 25℃±5℃ |

Refer to Spec | IEC60115-14.5 |

| Temperature coefficient of resistance |

TCR=(R-Ro)/Ro(T2-T1)X 10⁶ Ro:resistance of room temperature R:resistance of 125℃ T1:Room temperature T2:Temperature at 125℃ |

Refer to Spec | MIL-STD-202 Method 304 |

| Short time Overload | Apply overload for 5 seconds and measure the resistance change rate after standing for 24 hours 5 times the rated power for 5 seconds |

≤±0.5% | MIL-R-26E |

| Resistance to Soldering Heat |

260℃±5℃ time:10sec±1sec | ≤±0.5% | MIL-STD-202 Method 210 |

| Temperature Cycling | -55℃(15min)/+125℃(15min),1000 cycles | ≤±0.5% | MIL-STD-202 Method107G |

| Low temperature Storage |

-55℃ for 1000hours,No power | ≤±0.5% | MIL-STD-26E |

| High Temperature Storage |

125℃(1mΩ)/170℃(0.0005~0.00075mΩ)for 1000hours,No power |

≤±1% | IEC6011501-4.25 |

| Bias Humidity | +85℃,85%RH,10%bias,1000hours | ≤±0.5% | MIL-STD-202 Method103 |

| Mechanical shock | Condition C,100 g’s,6 msec,3 mutually perpendicular axes,in 6 directions,three impacts each for a total of 18 times 18 shocks. |

≤±0.5% | MIL-STD-202 Method 213 |

| Solderability | 245±5℃,2±0.5sec | At least 95%of surface area of electrode shall be covered with new solder |

IEC60115-1-4.17 JIS-C5201-4.17 |

| Operational life | 70℃±2℃,1000 hours,at rated power 1.5 hours “ON”,0.5 hours “OFF” |

≤±1% | MIL-STD-202 Method 108 |

| Insulation Resistance | 100V DC for 1 minute | >100 MΩ | JIS-C5201 |

| Board Flex | Bend the board(D)x=2 mm minimum,the duration of the applied forces shall be 10 Sec. |

≤±1% | JIS-C5201-14.32 |

| Terminal Strength | Apply a 17.7N(1.8 Kg)force to the side of a device being tested.This force shall be applied for 10 seconds. |

≤±1% | JIS-C5201-14.32 |

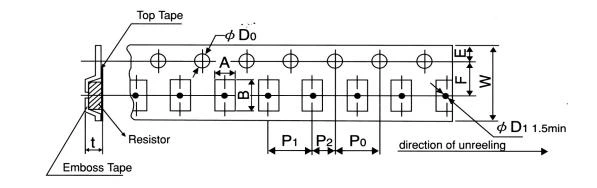

Tapping & Package

| Type | Pack | A ±0.2 |

B ±0.2 |

D0 +0.5-0 |

E ±0.1 |

F ±0.05 |

P0 ±0.1 |

P1 ±0.1 |

P2 ±0.1 |

W ±0.2 |

D1 ±0.05 |

T ±0.15 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2512 | Emboss | 3.60 | 6.90 | 1.50 | 1.75 | 5.50 | 4.00 | 4.00 | 2.00 | 12.00 | 1.50 | 1.20 |

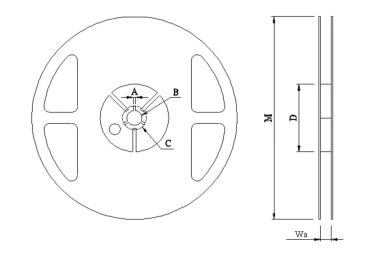

Reel Specification

Unit: Millimeters

| Type | A | B | C | D | M | W |

|---|---|---|---|---|---|---|

| 2512 | 2.00±0.5 | 13.50±0.5 | 21.00±0.5 | 80.00±1.0 | 178.00±2.0 | 13.80±0.5 |

Packaging

Quantity: 4, 000pcs

8mm wide tape on 178mm(7 inch)

diameter reel -specification EIA

Standard 481.

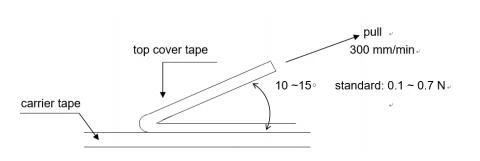

Peel strength of upper belt

Stripping speed: 300 mm / min; The peel force is between 0.1N and 0.7n.

Storage conditions & shelf life

It can be stored for 2 years under closed conditions with temperature of 5 ° C ~ 35 ° C and relative humidity of 40 ~ 75

Please avoid the following harsh environment during storage to avoid affecting the product

performance and solder connectivity: the places with corrosive gases such as sea breeze, Cl2, H2S,NH3, SO2 and NO2 shall be stored without direct sunlight.

Precautions for product use

When measuring the resistance value before welding, a special resistance meter with high precision shall be used. When measuring, a 4-wire probe or fixture must be used. When measuring parts with a wire measuring needle, the 4 measuring needles must indeed contact the parts.

Avoid damaging the protective layer during manual welding or clamping with tweezers.

When the PCB is divided or fixed on the support, be careful to avoid excessive bending causing mechanical stress to the resistor.

It shall be used within the rated power range within the specification, especially when the power exceeds the rated value, which may affect the reliability of the product