LMR20 Current Sense Resistor

LMR20 Series

Low Resistance Metal Strip Chip Resistors

Description

- Resistance range 0.5~100mR

- Rated power 1,2W

- Insulation resistance:≥220MΩ(DC 500V 1min )

- Low inductance design:<5nH (1MHz)

- Alloy Material, Shock Resistance

- Withstand voltage:500V

- Operating temperature range:- 65℃~170℃

Description

- Current sensing application

- Over current protection

- Servo motor control circuits

- Inverter power

- Electric control system

- Li-battery management system

Part number

LMR 20 F 1P0 R0005

【1】 【2】【3】【4】【5】

【 1 】Series Name: Low resistence Metal strip Chip Resistors

【2 】Chip size: 20:2010

【3】 Resistance Precision: D:±0.5% ; F:±1% ; G:±2% ; J:±5%

【4】 Power Rating:1P0= 1W ; 2P0=2W

【5】 Resistance Code: R0005: 0.5mΩ ; R100: 100mΩ

Standard Electrical Specifications

| Size | Power (W) | Resistance/mΩ | TCR (ppm/℃) | Operating Temperature (℃) |

|---|---|---|---|---|

| ±0.5%, ±1% ±2%,±5% | ||||

| 2010 | 1, 2 | 0.5 ~ 4 | ±75 | -65℃~170℃ |

| 5 ~ 100 | ±50 |

Note: Short Time Overload were tested with 2.5×Rated power for 10 s TCR(ppm/℃): Test conditions at 20℃~120℃ .

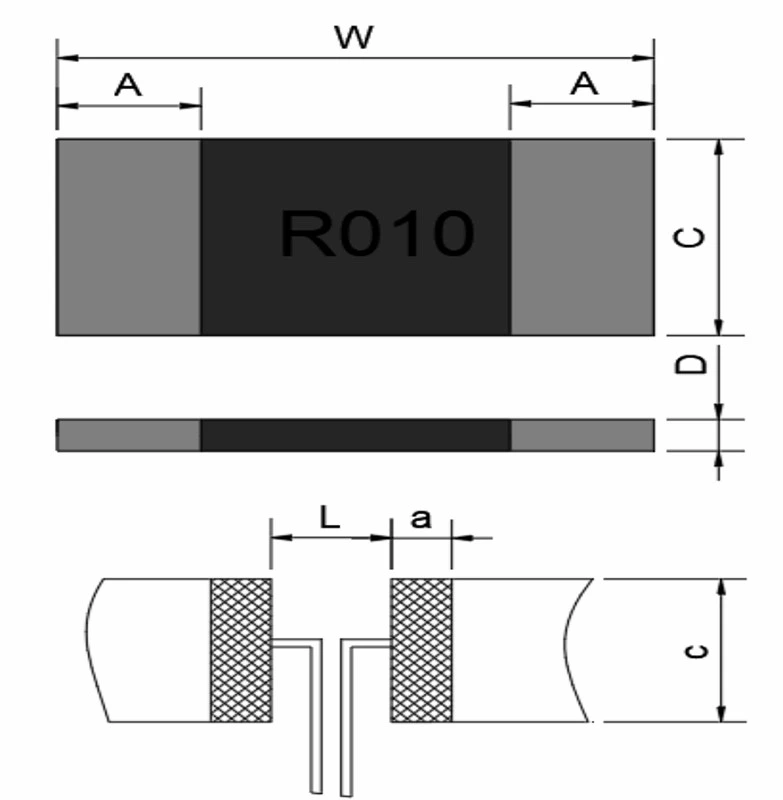

Products & Recommend Pad Dimension

Unit:mm

| Type | Resistance | W±0.2 | C±0.2 | A±0.2 | D±0.1 | L | a | c |

|---|---|---|---|---|---|---|---|---|

| 2010 | 0.5 ~ 0.9 | 5 | 2.5 | 1.3 | 0.8 | 2.1 | 2.1 | 3.5 |

| 2010 | 1 ~ 100 | 0.6 | 3.6 | 1.5 |

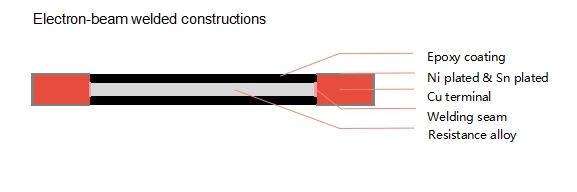

Welded Construction

Power Derating Curve

For resistors operated in ambient temperatures 70°C, power ratingshall bederated inaccording with the curve below:

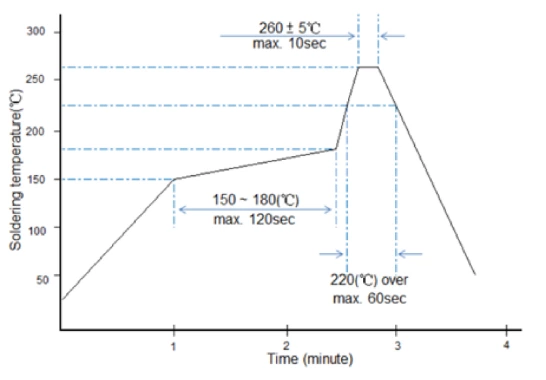

Recommended Solder Curve

Product Characteristics

| Item | Test condition/ Methods | Limited | Standard |

|---|---|---|---|

| Resistance | Measuring resistance value at room temperature 25℃±5℃ | Refer to Spec | IEC60115-1 4.5 |

| Temperature coefficient of resistance | TCR =(R-R0)/R0(T2-T1)X 106 T1 T2 R0 : resistance of room temperature R: resistance of 120℃ T1: Room temperature 20℃ T2: Temperature at 120℃ | Refer to Spec | MIL-STD-202 Method 304 |

| Short time Overload | 5×Rated power for 5 seconds 2.5×Rated power for 10 seconds | ≤±0.5% | MIL-STD-202 Method 210 |

| Resistance to Soldering Heat | 260℃± 5℃ time :10sec± 1sec | ≤±0.5% | MIL-STD-202 Method 210 |

| Temperature Cycling | -55℃ (15min)/+150℃(15min), 1000 cycles | ≤±0.5% | MIL-STD-202 Method107G |

| ESD Test | 1)Direct Contact (DC): ±6kV; 2)Air Discharge (AD): ±12kV, ±16kV, ±25kV | ≤±0.5% | AEC-Q200 REV D June 1 |

| High Temperature Storage | 125℃ for 100hours, No power | ≤±0.5% | IEC6011501-4.25 |

| Bias Humidity | +85℃, 85% RH ,10%bias, 1000hours | ≤±0.5% | MIL-STD-202 Method103 |

| Mechanical shock | Condition C ,100 g’s ,6 msec, 3 mutually perpendicular axes, in 6 directions, three impacts each for a total of 18 times 18 shocks. | ≤±0.5% | MIL-STD-202 Method 213 |

| Vibration | The frequency varies from 10HZ to 55HZ and return to 10HZ, shall be transferred in 1 min. Amplitude : 1.5mm, 3 directions, and 12 hours | ≤±0.5% | MIL-STD-202 Method 201 |

| Operational life | Condition D Steady State TA=125℃ at rated power. | ≤±0.5% | MIL-STD-202 Method 108 |

| Moisture resistance | MIL-STD-202,method106 ,No power, 7b not required | ≤±0.5% | MIL-STD-202 Method 106 |

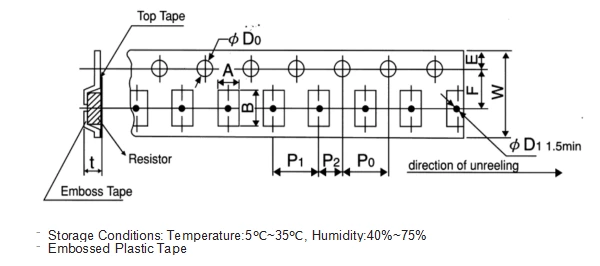

Tapping & Package

| Type | Pack | A ±2 | B ±2 | D0 +0.1 | E ±0.1 | F ±0.1 | P0 ±0.1 | P1 ±0.1 | P2 ±0.1 | W ±0.3 | t ±0.2 | Qty./reel |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2010 | Emboss | 2.75 | 5.5 | 1.50 | 1.75 | 5.50 | 4.00 | 4.00 | 2.00 | 12.00 | 0.82 | 3000 |

Packaging

Quantity: 3000pcs

16mm wide tape on 178mm(7 inch)

diameter reel -specification EIA

Standard 481

Storage

Storage Conditions: Temperature:5℃~35℃ , Humidity:40%~75%