APSRP27 Shunt Resistor

APSRP-T Series-Prosemi Shunt Resistors

Features

- Metal type Low-Resistance shuntresistor.

- Low TCR.

- Very low inductance.

- Halogen free, lead free and RoHS compliant.

- AEC-Q200 qualified available.

Applications

- Power modules.

- Frequency converters.

- Current sensor for power hybrid sources high current for automotive.

- Lithium battery protection board.

- Industrial Instrument and equipment

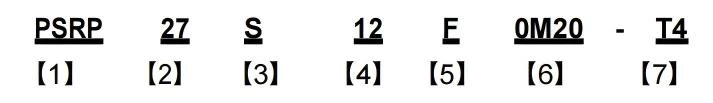

Part Number

Electrical Characteristics

| Size | Power Rating at 70℃*(W) |

Resistance Range(mΩ)** 0.5%,1.0%,2.0%,5.0% |

TCR (ppm/°℃) |

Element Material |

Operation Temperature Range |

|---|---|---|---|---|---|

| 1216 | 5 | 0.5 | ±50 | S | -65℃~+170℃ |

| 3 | 1 | ±50 | M | ||

| 2726 | 12 | 0.2 | ±75 | S | |

| 11 | 0.3 | ±75 | M | ||

| 9 | 0.5 | ±75 | |||

| 8 | 0.7 | ±75 | |||

| 7 | 1 | ±75 | |||

| 6 | 2 | ±50 | K | ||

| 5 | 3 | ±50 | |||

| 4 | 4 | ±50 | |||

| 3 | 5 | ±50 | |||

| 4026 | 12 | 0.2 | ±75 | S | -65℃~+170℃ |

| 11 | 0.3 | ±75 | M | ||

| 9 | 0.5 | ±75 | |||

| 8 | 0.7 | ±75 | |||

| 7 | 1 | ±75 | |||

| 6 | 2 | ±50 | K | ||

| 5 | 3 | ±50 | |||

| 4 | 4 | ±50 | |||

| 3 | 5 | ±50 |

Resistance Values of the 2726 Series, 4~6W Resistors

| Manufacturable Resistance Values ( Ω ) | ||||||||

|---|---|---|---|---|---|---|---|---|

| 0.0002ohm | 0.0003ohm | 0.0005ohm | 0.0007ohm | 0.001ohm | 0.002ohm | 0.003ohm | 0.004ohm | 0.005ohm |

| 0M20 | 0M30 | 0M50 | 0M70 | R001 | R002 | R003 | R004 | R005 |

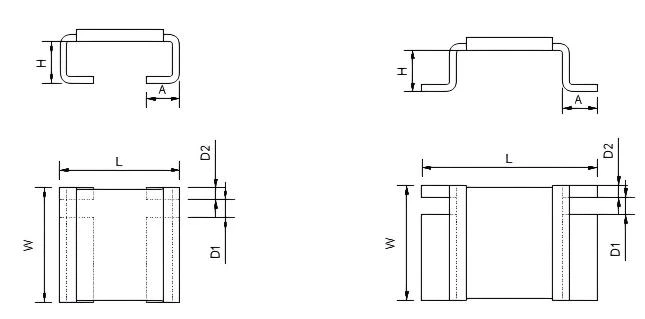

Physical Dimensions

1216&2726 4026

Unit:mm

| Size | L | W | H | A | D1 | D2 |

|---|---|---|---|---|---|---|

| 1216 | 3.1±0.2 | 4.0±0.2 | 1.5±0.1 | 1.1±0.1 | 0.7±0.1 | 0.5±0.1 |

| 2726 | 6.9±0.2 | 6.6±0.2 | 2.6±0.2 | 1.95±0.1 | 1.0±0.1 | 0.7±0.1 |

| 4026 | 10.1±0.2 | 6.6±0.2 | 2.6±0.2 | 1.95±0.1 | 1.0±0.1 | 0.7±0.1 |

Recommended Solder Pad Layout

Unit: mm

| Size | a | b | C | d1 | d2 |

|---|---|---|---|---|---|

| 1216 | 4.1 | 1.5 | 3.6 | 2.9 | 0.7 |

| 2726 | 7.3 | 2.9 | 7.8 | 5.6 | 0.9 |

| 4026 | 7.3 | 2.9 | 10.8 | 5.6 | 0.9 |

Four pin testing position

Unit: mm

| Size | L1 | W1 |

|---|---|---|

| 1216 | 2.0 | 2.2 |

| 2726 | 5.0 | 3.9 |

| 4026 | 8.1 | 3.8 |

Product Marking

1216

1216

2726/4026

2726/4026

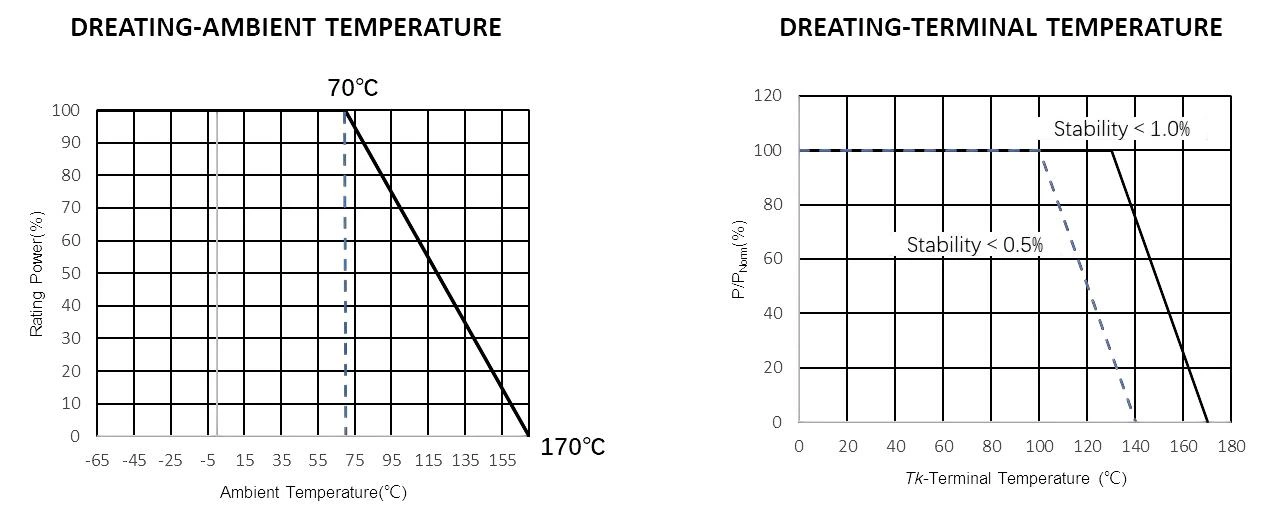

Power Derating Curve

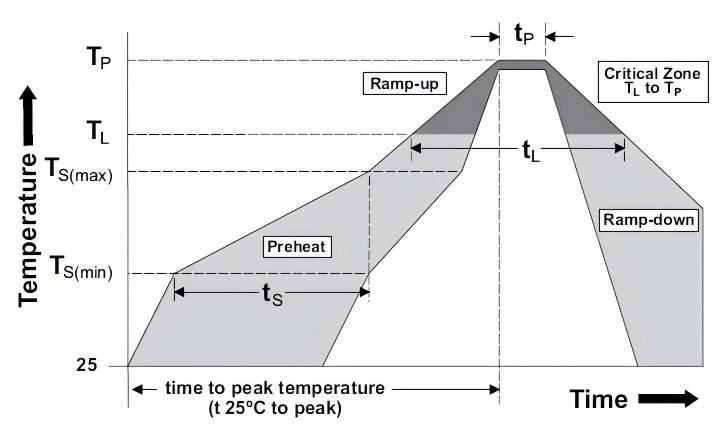

RecommendedSolderCurve

| Reflow Condition | Pb-Free assembly | |

| Pre heat | -Temperature Min(Ts(min)) |

150℃ |

| -Temperature Max (Ts(max)) |

200℃ | |

| -Time(Min to Max)(ts) | 60-120 secs | |

| Average ramp up rate (Liquidus Temp(TL) to peak |

5℃/second max | |

| Ts(max)to TL-Ramp-up Rate | 5℃/second max | |

| Reflow | -Temperature(TL) (Liquidus) |

217℃ |

| -Time (tL) | 60-150 seconds | |

| Peak Temperature(TP) | 260℃ | |

| Time within 5℃ of actual peak Temperature (tp) |

20-40 seconds | |

| Ramp-down Rate | 5℃/second max | |

| Time 25℃ to peak Temperature(TP) | 8 minutes Max. | |

| Wave Soldering | Not applicable | |

| Hand Soldering | 350℃,5 seconds max. | |

Product Characteristics

| Item | Test condition/Methods | Limited | Standard |

|---|---|---|---|

| Resistance | Measuring resistance value at room temperature 25℃±5℃ |

Refer to Spec |

IEC60115-14.5 |

| Temperature Coefficient of Resistance |

TCR(ppm/°℃)=(R2-R1/R1*(T2-T1))X 10⁶ R1:resistance value measured at room temperature(Ω) R2:Resistance measured at 125°C(Ω) T1:room temperature(°C) T2:125℃ |

Refer to Spec |

IEC 60115-14.8 |

| Short Time Overload |

Apply 3 times rated power for 5 seconds,and measure the resistance change after standing for 24 hours. |

≤±0.5% | IEC 60115-14.13 |

| High Temperature Storage |

170℃ for 1000 hours,No power. | ≤±1% | MIL-STD-202 Method 108 |

| Temperature Cycling |

-55℃(15min)/+150℃(15min),1000 cycles, transition time less than 1 minute |

≤±0.5% | JESD22-A104 |

| Bias Humidity | +85℃,85%RH,10%of operating power, 1000hours |

≤±0.5% | MIL-STD-202 Method103 |

| Operational life | 70℃±2℃,1000 hours,at rated power 1.5 hours “ON”,0.5 hours “OFF”. |

≤±1% | MIL-STD-202 Method 108 |

| Mechanical shock |

Condition C,100 g's ,6 msec,3 mutually perpendicular axes,in 6 directions,three impacts each for a total of 18 times 18 shocks. |

≤±0.5% | MIL-STD-202 Method 213 |

| Vibration | 5g's for 20 minutes 12 cycles each of 3 orientations. Test from 10 Hz-2000 Hz |

≤±0.5% | MIL-STD-202 Method 204 |

| Resistance to Soldering Heat |

Condition K,temperature above 217℃,60s-150s | ≤±0.5% | MIL-STD-202 Method 210 |

| Solderability | 245±5℃ time:5sec+0/-0.5sec. | ≥95% | J-STD-002 |

Packaging

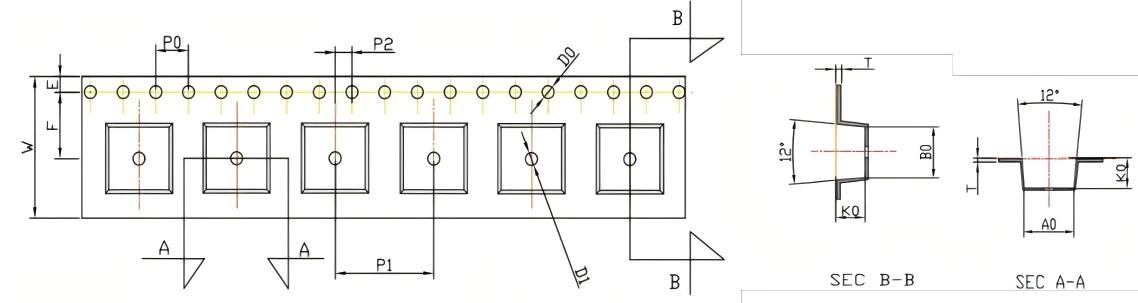

Tape Dimensions

| Series | A0(mm) | B0(mm) | W(mm) | E(mm) | F(mm) | T(mm) |

|---|---|---|---|---|---|---|

| 1216 | 3.40±0.20 | 4.20±0.20 | 12.00±0.30 | 1.75±0.10 | 5.50±0.10 | 0.30±0.10 |

| 2726 | 6.90±0.10 | 7.20±0.10 | 16.00±0.10 | 1.75±0.10 | 7.50±0.10 | 0.40±0.05 |

| 4026 | 6.9±0.20 | 10.40±0.20 | 24.00±0.30 | 1.75±0.10 | 11.50±0.10 | 0.40±0.10 |

| Series | P0(mm) | P1(mm) | P2(mm) | D0(mm) | D1(mm) | K0(mm) |

|---|---|---|---|---|---|---|

| 1216 | 4.00±0.10 | 8.00±0.10 | 2.00±0.05 | 1.50±0.10 | 1.50±0.10 | 2.30±0.10 |

| 2.80±0.10 | ||||||

| 2726 | 4.00±0.10 | 12.00±0.10 | 2.00±0.1 | 1.50+0.10/-0.00 | 1.55±0.05 | 3.60±0.10 |

| 4.50±0.10 | ||||||

| 4026 | 4.00±0.10 | 12.00±0.10 | 2.00±0.05 | 1.50±0.10 | 1.50±0.10 | 3.60±0.10 |

| 4.40±0.10 |

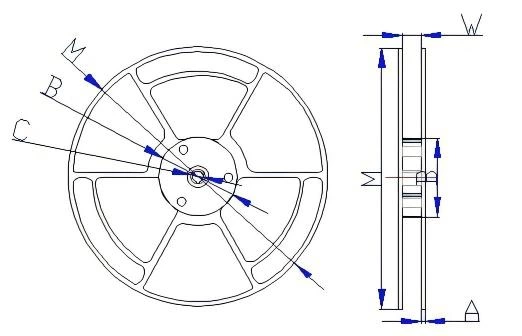

Reel Dimensions

| Series | W(mm) | M(mm) | A(mm) | B(mm) | C(mm) |

|---|---|---|---|---|---|

| 1216 | 12.40+2/-0 | 330.00±2 | 2.30±0.50 | 100.0±1.5 | 13.5±0.50 |

| 2726 | 16.40+2/-0 | 330.00±2 | 2.30±0.50 | 100.0±1.5 | 13.5±0.50 |

| 4026 | 24.40+2/-0 | 330.00±2 | 2.30±0.50 | 100.0±1.5 | 13.5±0.50 |

Quantity of Package

| Type | Quantity(pcs) |

|---|---|

| 1216 | 0.2~0.3mΩ:2500 0.5-3mΩ:3000 |

| 2726 | 0.2~0.5mΩ:1000 0.7-5mΩ:1500 |

| 4026 | 0.2-0.3mΩ:1000 0.5-5mΩ:1500 |

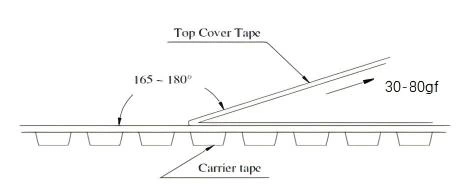

Peeling Test

Storage

1. The temperature condition must be controlled at 25±5℃,The R.H. must be controlled at 60±15%. Store in accordance with this requirement, and the validity period is two years after the date of manufacture.

2. Please avoid the mentioned harsh environment below when storing to ensure product performance and its’ solderability. Places exposed to sea breeze or other corrosive gas, such as Cl2, H2S, NH3, SO2 and NO2.

3. When the product is moved and stored, please ensure the correct orientation of the box. Do not drop or squeeze the box. Otherwise, the electrode or the body of the product may be damaged.