MFR12A

Low-Resistance Metal Film Chip Resistor

Description

- Low Resistance / TCR / Inductance( ≤5 nH)

- Excellent long-term stability

- High precision current sensing

- High power capability

- Halogen free and lead free

- RoHS compliant

- AEC-Q200 compliant

Applications

- Consumer electronics

- Laptops

- Communication devices

- Measuring instrument

- Industrial / Power supply

- Battery pack

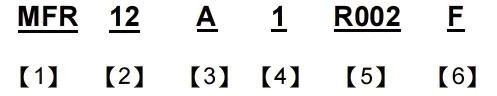

Part number

【1】Series Name: Low-Resistance Metal Film Chip Resistor

【2】Chip Size: 25:2512, 12: 1206, 08:0805

【3】Terminals: A:2 terminals , B:4 terminals

【4】Power Rating: 1=1W, 2=2W, 3 =3W, D=0.75W, E=0.5W, F=0.25W, G=0.125W

【5】Resistance Code: R680: 680mΩ, 1R50: 1.5Ω

【6】Resistance Precision: D:±0.5%, F:±1%, E:±2%, G:±5%

Electrical Characteristics

| Part number |

Power Rating at 70℃ (W) |

Resistance Range 0.5%,1.0%,2.0%,5.0% |

TCR (ppm/℃) |

Operation Temperature Range |

|---|---|---|---|---|

| MFR08A | 1/8 | 39mΩ≤R<50mΩ | ±150 | -55℃~+155℃ |

| 50mΩ≤R<100mΩ | ±100 | |||

| 100mQ≤R<10Ω | ±50 | |||

| 1/4 | 39mΩ≤R<50mΩ | ±150 | ||

| 50mΩ≤R<100mΩ | ±100 | |||

| 100mQ≤R<10Ω | ±50 | |||

| 1/2 | 39mQ≤R<50mΩ | ±150 | ||

| 50mΩ≤R<100mΩ | ±100 | |||

| 100mQ≤R<10Ω | ±50 | |||

| MFR12A | 1/4 | 39mΩ≤R<50mΩ | ±150 | |

| 50mΩ≤R<100mΩ | ±100 | |||

| 100mQ≤R<10Ω | ±50 | |||

| 1/2 | 39mΩ≤R<50mΩ | ±150 | ||

| 50mQ≤R<100mQ | ±100 | |||

| 100mΩ≤R<10Ω | ±50 | |||

| 3/4 | 39mΩ≤R<50mΩ | ±150 | ||

| 50mΩ≤R<100mΩ | ±100 | |||

| 100mQ≤R<100 | ±50 | |||

| 1 | 39mΩ≤R<50mΩ | ±150 | ||

| 50mΩ≤R<100mΩ | ±100 | |||

| 100mΩ≤R<100 | ±50 | |||

| MFR25A | 1 | 100mQ≤R<10Ω | ±50 | |

| 2 | ||||

| 3 |

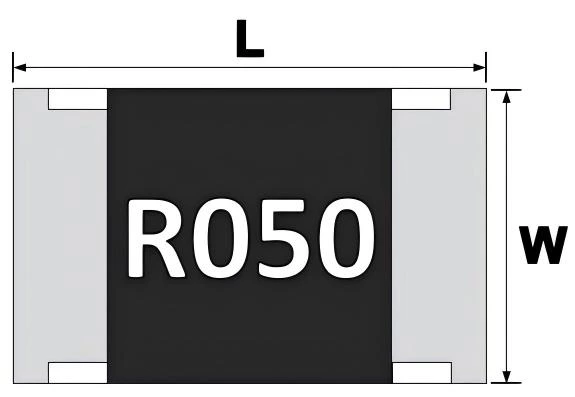

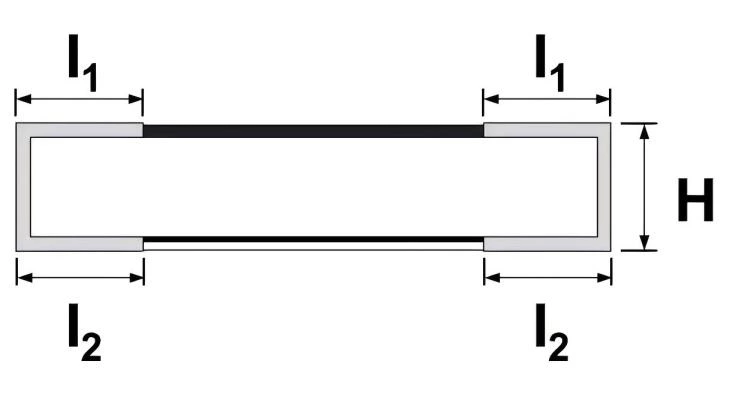

Physical Dimensions

| Part number | L | W | H | I1 | 12 |

|---|---|---|---|---|---|

| MFR08A | 2.00±0.10 | 1.25±0.10 | 0.55±0.10 | 0.35±0.20 | 0.40±0.20 |

| MFR12A | 3.10±0.10 | 1.60±0.10 | 0.55±0.10 | 0.40±0.20 | 0.45±0.20 |

| MFR25A | 6.30±0.20 | 3.20±0.20 | 0.55±0.10 | 0.65±0.25 | 0.65±0.25 |

| MFR25A(3W) | 6.30±0.20 | 3.20±0.20 | 0.70±0.15 | 0.65±0.25 | 0.65±0.25 |

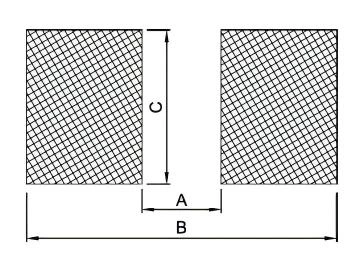

Recommended Solder Pad Layout

Unit: mm

| Part number | A | B | C |

|---|---|---|---|

| MFR08A | 1.30 | 2.90 | 1.45 |

| MFR12A | 2.20 | 4.20 | 1.80 |

| MFR25A | 4.90 | 8.10 | 3.40 |

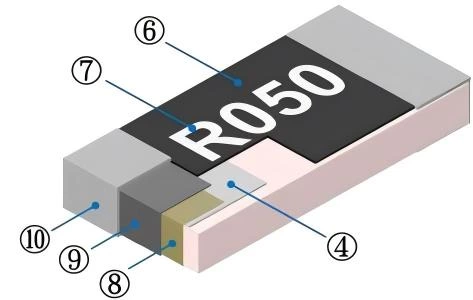

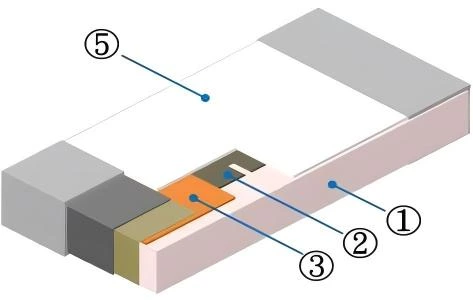

Construction

| 1 | Alumina Substrate |

|---|---|

| 2 | Resistive Layer |

| 3 | Bottom Inner Electrode (Cu) |

| 4 | Top Inner Electrode |

| 5 | Bottom Protective Overcoat (White) |

| 6 | Top Protective Overcoat |

| 7 | Marking |

| 8 | Side Inner Electrode |

| 9 | Barrier Layer(Ni) |

| 10 | Solder coating (Sn) |

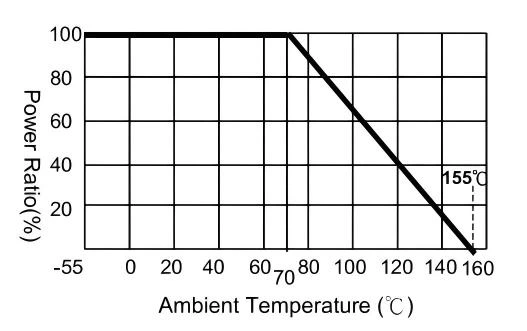

Power Derating Curve

For resistors operated in ambient temperatures 70°C, power rating shall be derated in according with the curve below:

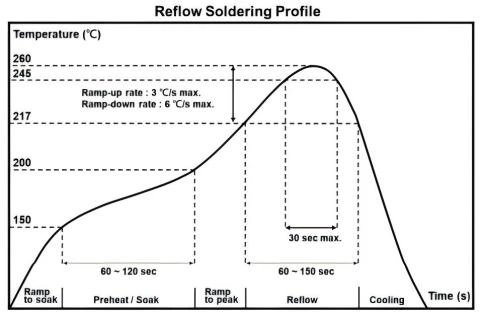

Recommended Solder Curve

Wave solder Temperature condition

Solder reflow Temperature condition

Rework temperature (hot air equipment): 350°C, 3~5seconds

Recommended reflow methods: IR, vapor phase oven, hot air oven

If reflow temperatures exceed the recommended profile, devices may not meet the performance requirements.

Product Characteristics

| Item | Test condition/Methods | Limited | Standard |

|---|---|---|---|

| Temperature coefficient of resistance |

TCR=(R-R₀)/R₀ (T2-T1)X 10⁶ R₀ :resistance of room temperature R:resistance of 125℃ T1:Room temperature T2:Temperature at 125℃ |

Refer to Spec | MIL-STD-202 Method 304 |

| Short time Overload | Standard power:6.25 times the rated power for 5 seconds High power (2X/4X)and wide terminal type:5 times the rated power for 5 seconds |

≤±1.0% | JIS-C-5201-14.13 IEC-60115-14.13 |

| Insulation Resistance |

100VDC for 1 minute. | ≥10GΩ | JIS-C-5201-146 IEC-60115-14.6 |

| Resistance to Solvent |

The tested resistor be immersed into isopropyl alcohol of 20~25℃ for 60 secs Then the resistor is left in the room for 48 hrs. |

≤±1.0% | JIS-C-5201-14.29 |

| Resistance to Soldering Heat |

260℃±5℃ time:10sec | ≤±1.0% | JIS-C-5201-14.18 IEC-60115-14.18 |

| Solderability | 245℃±5℃ time:3sec | Solder coverage over 95%No Visual damage |

IEC60115-14.17 JIS-C-5201-14.17 |

| Leaching | 260℃±5℃ time:30sec | Solder coverage over 95%No Visual damage |

JIS-C-5201-14.18 IEC-60068-2-588.2.1 |

| Temperature Cycling |

-55℃1+155℃,300 cycles | ±1.0% No Visual damage |

JIS-C-5201-14.19 IEC-60115-14.19 |

| High Temperature |

155±5℃ for 1000hours,No power | ≤±1.0% | JIS-C5201-14.25 IEC 60068-2-2 |

| Storage Bias Humidity |

+85℃,85%RH,10%bias,1000hours | ≤±0.5% | MIL-STD-202 Method103 |

| Operational life | 70℃±2℃,1000 hours,at rated power 1.5 hours “ON”,0.5 hours "OFF” |

≤±1.0% | JIS-C-5201-14.25 IEC-60115-14.25.1 |

| Damp Heat with Load |

40℃±2℃,90-95%R.H.RCW or Max. 1000 hours,1.5 hours "ON”,0.5 hours“ OFF” |

≤±1.0% | JIS-C-5201-14.24 IEC-60115-1424 |

| Bending Strength | Bending once for 5 seconds: 1206=3mm 2512=2mm 0805=5mm |

±1.0% No Visual damage |

JIS-C-5201-14.33 IEC-60115-14.33 |

Note : Measurement at 24±4 hours after test conclusion for all reliability tests-parts.

Packaging

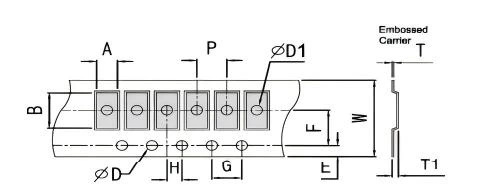

Tape Dimensions

Unit: mm

| Type | A | B | W | E | F | G | H | T | D | P |

|---|---|---|---|---|---|---|---|---|---|---|

| MFR08A | 1.55±0.2 | 2.30±0.2 | 8.0±0.2 | 1.75±0.1 | 3.5±0.05 | 4±0.1 | 2±0.05 | 0.75±0.1 | 1.5+0.1/-0 | 4.0±0.1 |

| MFR12A | 1.9±0.2 | 3.05±0.2 | 8.0±0.2 | 1.75±0.1 | 3.5±0.05 | 4±0.1 | 2±0.05 | 0.75±0.1 | 1.5+0.1/-0 | 4.0±0.1 |

Embossed Dimensions

Unit: mm

| Type | A | B | W | E | F | G |

|---|---|---|---|---|---|---|

| MFR25A | 3.4±0.2 | 6.7±0.2 | 12±0.1 | 1.75±0.1 | 5.5±0.05 | 4±0.1 |

| H | T | D | D1 | T1 | P | |

| 2±0.05 | 0.23±0.1 | 1.5+0.1/-0 | 1.5±0.1 | 0.85±0.15 | 4±0.1 |

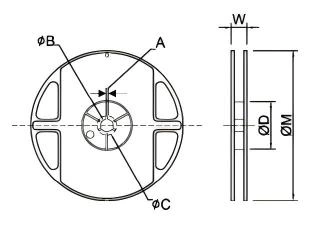

Reel Dimensions

Unit: mm

| Type | SIZE | A | B | C | D | W | M |

|---|---|---|---|---|---|---|---|

| MFR08A | 7 inch reel | 2.0±0.5 | 13.5±1.0 | 21±1.0 | 60.0±1.0 | 11.5±2.0 | 178±2.0 |

| MFR12A | 7 inch reel | 2.0±0.5 | 13.5±1.0 | 21±1.0 | 60.0±1.0 | 11.5±2.0 | 178±2.0 |

| MFR25A | 7 inch reel | 2.0±0.5 | 13.5±1.0 | 21±1.0 | 60.0±1.0 | 16.0±2.0 | 178±2.0 |

Quantity of Package

| Type | MFR08A | MFR12A | MFR25A |

|---|---|---|---|

| Quantity(pcs) | 5000 | 5000 | 4000 |