MFR20

Low-Resistance Metal Film Chip Resistor

Description

- Low Resistance / TCR

- Excellent high-frequency characteristics(≤2 nH)

- Excellent long-term stability

- High precision current sensing

- Ultra Anti-surge characteristics superior to standard Others metal film resistors

- Halogen free and lead free

- RoHS compliant

- AEC-Q200 compliant

Applications

- Consumer electronics

- Laptops

- Communication devices

- Measuring instrument

- Industrial / Power supply

- Battery pack

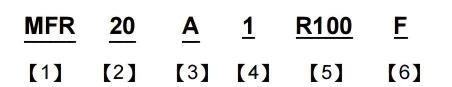

Part number

【1】Series Name: Low-Resistance Metal Film Chip Resistor

【2】Chip Size: 20: 2010

【3】Terminals: A:2 terminals , B:4 terminals

【4】Power Rating: D=0.75W, 1 =1.5W

【5】Resistance Code: R100: 100mΩ

【6】Resistance Precision: D:±0.5%, F:±1%, E:±2%, G:±5%

Electrical Characteristics

| Part number |

Power Rating at 70℃ (W) |

Resistance Range 0.5%,1.0%,2.0%,5.0% |

TCR (ppm/°C) |

Operation Temperature Range |

|---|---|---|---|---|

| MFR20A | 0.75 | 100m≤R≤10Ω | ±50 | -55℃~+155℃ |

| 1.5 |

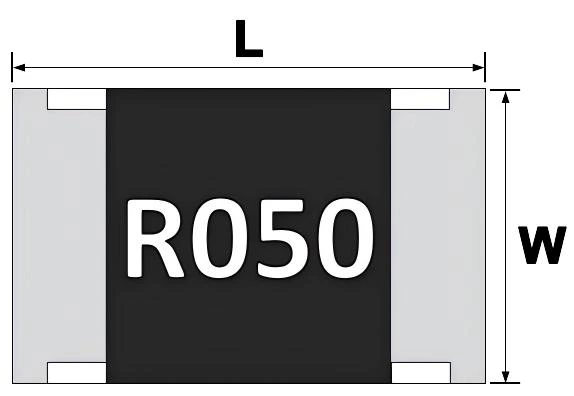

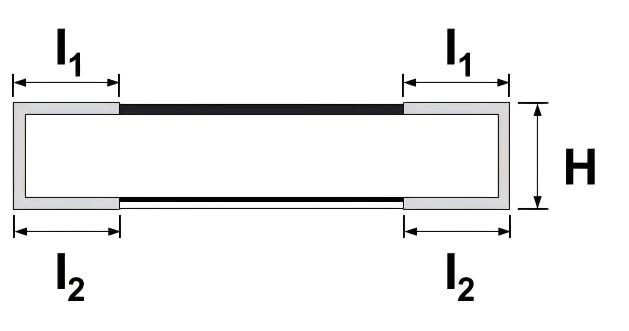

Physical Dimensions

Unit: mm

| Part number | Power | L | W | H | I1 | I2 |

|---|---|---|---|---|---|---|

| MFR20A | 0.75W | 5.00±0.20 | 2.50±0.15 | 0.55±0.10 | 0.60±0.25 | 0.60±0.25 |

| 1.5W |

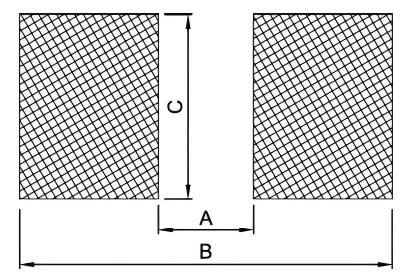

Recommended Solder Pad Layout

Unit: mm

| Part number | A | B | C |

|---|---|---|---|

| MFR20A | 3.80 | 6.60 | 2.70 |

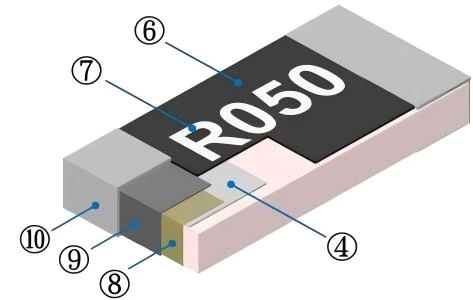

Construction

| 1 | Alumina Substrate |

| 2 | Resistive Layer |

| 3 | Bottom Inner Electrode(Cu) |

| 4 | Top Inner Electrode |

| 5 | Bottom Protective Overcoat (White) |

| 6 | Top Protective Overcoat |

| 7 | Marking |

| 8 | Side Inner Electrode |

| 9 | Barrier Layer(Ni) |

| 10 | Solder coating(Sn) |

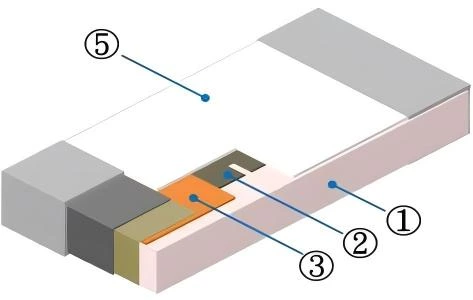

Power Derating Curve

For resistors operated in ambient temperatures 70°C, power rating shall be derated in according with the curve below:

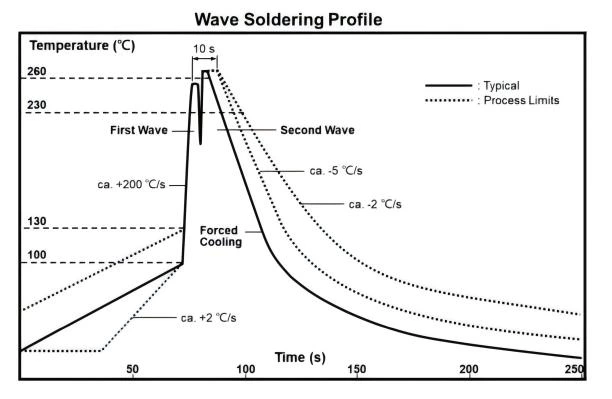

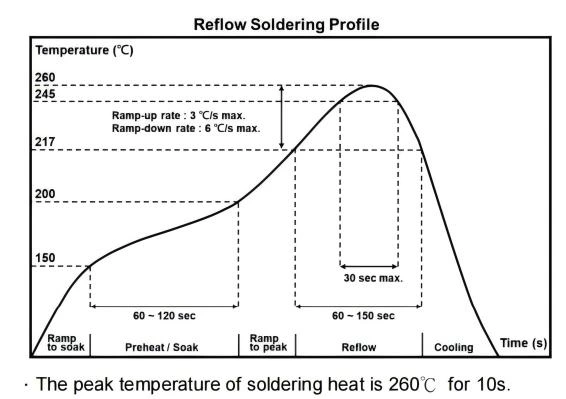

Recommended Solder Curve

Wave solder Temperature condition

Solder reflow Temperature condition

Rework temperature (hot air equipment): 350°C, 3~5seconds

Recommended reflow methods: IR, vapor phase oven, hot air oven

If reflow temperatures exceed the recommended profile, devices may not meet the performance requirements.

Product Characteristics

| Item | Test condition/Methods | Limited | Standard |

|---|---|---|---|

| Temperature coefficient of resistance |

TCR=(R-R0)/R0(T2-T1)X 10⁶ R0 :resistance of room temperature R:resistance of 125℃ T1:Room temperature T2:Temperature at 125℃ |

Refer to Spec | MIL-STD-202 Method 304 |

| Short time Overload |

Standard power:6.25 times rated power whichever is less for 5 seconds. |

≤±1.0% | JIS-C-5201-14.13 IEC-60115-14.13 |

| High power(2X/4X)and wide terminal type:5 times rated power whichever is less for 5 seconds. |

|||

| Insulation Resistance |

100VDC for 1 minute. | ≥10GΩ | JIS-C-5201-146 IEC-60115-14.6 |

| Dielectric Withstanding Voltage |

Applied 500VAC for 1 minute. | No short or burned on the appearance. |

JIS-C5201-14.7 |

| Resistance to Soldering Heat |

260℃±5℃ time:10sec | ≤±1.0% | JIS-C-5201-14.18 IEC-60115-14.18 |

| Solderability | 245℃±5℃ time:3sec | Solder coverage over 95%No Visual damage |

IEC60115-14.17 JIS-C-5201-14.17 |

| Leaching | 260℃±5℃ time:30sec | Solder coverage over 95%No Visual damage |

JIS-C-5201-14.18 IEC-60068-2-588.2.1 |

| Rapid Change of Temperature |

-55℃ to+155℃,300 cycles. | ±1.0% No Visual damage |

JIS-C-5201-14.19 IEC-60115-14.19 |

| Resistance to Solvent |

The tested resistor be immersed into isopropyl alcohol of 20~25℃ for 60 secs Then the resistor is left in the room for 48 hrs. |

±1.0% No Visual damage |

JIS-C-5201-14.29 |

| High Temperature |

155±5C for 1000hours,No power | ≤±1.0% | IEC60115-14.25 |

| Storage Bias Humidity |

1,000 hours;85℃/85%RH,10%of operating power.Measurement at 24±4 hours after test conclusion. |

≤±0.5% | MIL-STD-202 Method103 |

| Operational life | 70℃±2℃,1000 hours,at rated power 1.5 hours “ON”,0.5 hours "OFF” |

≤±0.5% | JIS-C-5201-14.24 IEC-60115-1424 |

| Damp Heat with Load |

40℃±2℃,90-95%R.H.RCW or Max. 1000 hours,1.5 hours “ON”,0.5 hours“ OFF” |

≤±1.0% | JIS-C-5201-14.24 IEC-60115-1424 |

| Terminal Strength (SMD) |

Pressurizing force for 10 seconds 2010:17.7N |

No broken | JIS-C5201-14.32 AEC Q200-006 |

| Bending Strength | Bending once for 5 seconds: 2010=2mm |

±1.0% No Visual damage |

JIS-C-5201-14.33 IEC-60115-14.33 |

Note : Measurement at 24±4 hours after test conclusion for all reliability tests-parts.

Packaging

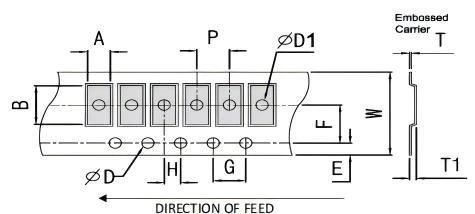

Embossed Dimensions

| Type | A | B | W | E | F | G |

|---|---|---|---|---|---|---|

| MFR20A | 2.8±0.2 | 5.6±0.2 | 12±0.1 | 1.75±0.1 | 5.5±0.05 | 4±0.1 |

| H | T | D | D1 | T1 | P | |

| 2±0.05 | 0.23±0.1 | 1.5+0.1/-0 | 1.5±0.1 | 0.85±0.15 | 4±0.1 |

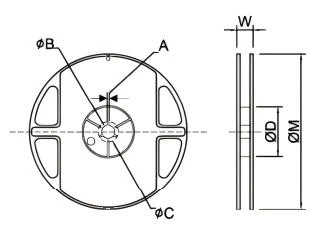

Reel Dimensions

Unit: mm

| Type | SIZE | Quantity (pcs) |

A | B | C | D | W | M |

|---|---|---|---|---|---|---|---|---|

| MFR20A | 7 inch reel | 4000 | 2.0±0.5 | 13.5±1.0 | 21±1.0 | 60.0±1.0 | 16.0±2.0 | 178±2.0 |

Storage

Storage time at the environment temp: 25±5℃& humidity: 60±20% is valid for one year from the date of delivery.