LMS06

Description

- Proprietary processing technique produces

- extremely low resistance values

- Very low inductance

- Low thermal EMF

- Metal Foil

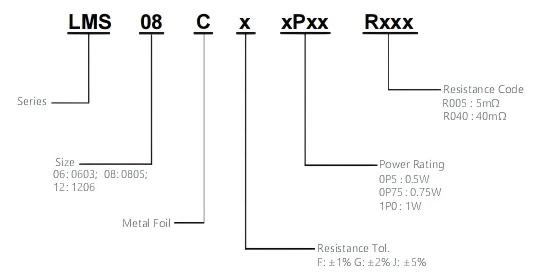

Part Numbering System

| Parameter | Standard |

|---|---|

| Power Rating | 0.5W /0.75W/1.0W |

| Resistance Value | 3~200mΩ |

| Operating Temperature Range | -55 to +155℃ |

| Component Temperature Coefficient(TCR) | ±50 ppm/℃ |

| Maximum Working Voltage (V) | (PxR)1/2 |

| Rating current (A) | (P/R)1/2 |

P=Power Rating; R=Resistance Value

Standard Electrical Specifications

| Type | Rating Power at 70℃ |

T.C.R. (ppm/℃) |

Resistance Range (mΩ) F:±1.0% G:±2.0% J:±5.0% |

Operating Temperature(℃) |

|---|---|---|---|---|

| LMS06 | 0.5W | ±50 | 3-20 | -55~+155℃ |

| LMS08 | 0.75W | 5-100 | ||

| LMS12 | 1.0W | 3-200 |

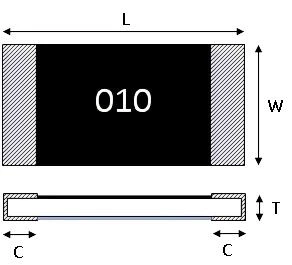

Dimensions

Unit: Millimeters

| Type | L | W | C | T |

|---|---|---|---|---|

| LMS06 | 1.60±0.20 | 0.8±0.20 | 0.40±0.20 | 0.60±0.20 |

| LMS08 | 2.00±0.20 | 1.25±0.20 | 0.40±0.30 | 0.70±0.20 |

| LMS12 | 3.20±0.20 | 1.60±0.20 | 0.50±0.30 | 0.70±0.20 |

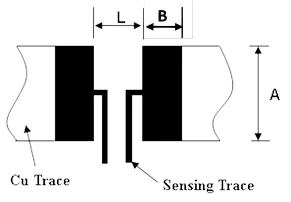

Recommended land pattern

Unit: Millimeters

| Series | Resistance(mΩ) | A | L | B |

|---|---|---|---|---|

| LMS06 | 3≤R≤20 | 1.0 | 0.6 | 1.1 |

| LMS08 | 5≤R≤100 | 1.4 | 1.2 | 1.0 |

| LMS12 | 5≤R≤35 | 1.8 | 1.6 | 1.55 |

| 36≤R≤200 | 2.2 | 1.35 |

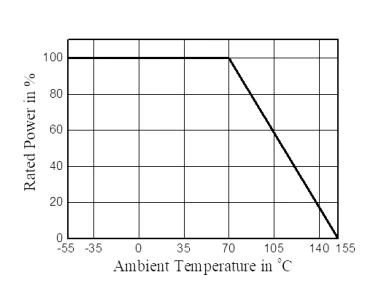

Derating Curve

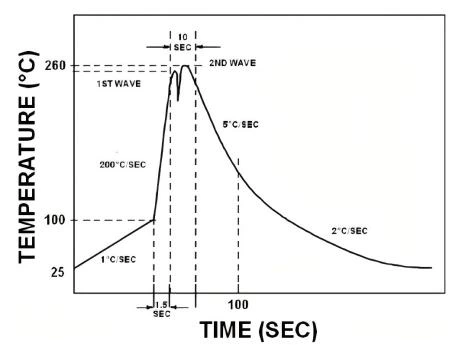

Recommend Wave-Solder profile

ProductCharacteristics

| Item | Test condition/Methods | Limited | Standard |

|---|---|---|---|

| Resistance | Measuring resistance value at room temperature 25℃±5℃ |

Refer to Spec | IEC60115-14.5 |

| Temperature coefficient of resistance |

TCR=(R-R0)/R0(T2-T1)X 10⁶ T1 T2 R0:resistance of room temperature R:resistance of 125℃ T1:Room temperature T2:Temperature at 125℃ |

Refer to Spec | MIL-STD-202 Method 304 |

| Short time Overload | 5 X rated power for 5s | ≤±1% | MIL-R-26E |

| Resistance to Soldering Heat |

260℃±5℃ time:10sec±1sec | ≤±0.5% | MIL-STD-202 Method 210 |

| Temperature Cycling | -55℃(30min)/+125℃(30min),1000 cycles,24 ±4 hours |

≤±1% | MIL-STD-202 Method107G |

| Moisture Resistance |

T=24 hours /Cycle,10 Cycles.Notes:Steps 7a& 7b not required.Unpowered |

≤±1% | MIL-STD-202 |

| High Temperature Storage |

125℃ for 1000hours,24±4 hours,No power | ≤±1% | IEC6011501-4.25 |

| Bias Humidity | +85℃,85%RH,10%bias1.5 hours “ON”,0.5 hours “OFF”,1000hours |

≤±1% | MIL-STD-202 Method103 |

| Solderability | 235±3℃,3±0.5sec | >95%area covered with tin |

IEC60115-1-4.17 JIS-C5201-4.17 |

| Mechanical Shock | Wave Form:Tolerance for half sine shock pluse. Peak value is 100g’s.Normal duration(D)is 6(ms) |

<±1% | MIL-STD-202 |

| Operational life | 125℃,1000 hours,at 35%rated power | ≤±2% | MIL-STD-202 Method 108 |

| Vibration | 5 g's for 20 min.,12 cycles each of 3 orientations Note:Test from 10-2000 Hz. |

<±1% | MIL-STD-202 |

| Thermal Shock | -55°℃/+155℃.Note:Number of cycles required-300,Maximum transfer time-20 seconds, Dwell time-15 minutes.Air-Air. |

<±1% | MIL-STD-202 |

| ESD | verify the voltage setting at 500V | <±1% | AEC-Q200-002 |

| Board Flex (Bending) |

The duration of the applied forces shall be 60 (+5)Sec 3mm deflection |

<±1% | AEC-Q200-005 |

| Terminal Strength (SMD) |

LMS06~LMS12:Force of 1.8kg for 60 seconds Remarks:0201-NA |

<±1% | AEC-Q200-006 |

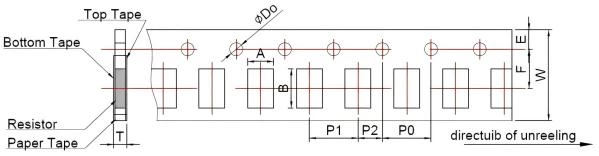

Tapping & Package

| Type | Pack | A ±0.15 |

B ±0.2 |

W ±0.2 |

E ±0.1 |

F ±0.05 |

P0 ±0.1 |

P1 ±0.1 |

P2 ±0.1 |

D0 ±0.1 |

T ±0.1 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0603 | Emboss | 1.10 | 1.90 | 8.0 | 1.75 | 3.50 | 4.00 | 4.00 | 2.00 | 1.55 | 0.85 |

| 0805 | Emboss | 1.60 | 2.40 | 8.0 | 1.75 | 3.50 | 4.00 | 4.00 | 2.00 | 1.55 | 1.05 |

| 1206 | Emboss | 2.00 | 3.60 | 8.0 | 1.75 | 3.50 | 4.00 | 4.00 | 2.00 | 1.55 | 1.05 |

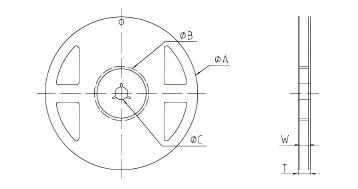

Reel Specification

Unit: Millimeters

| Type | A | B | C | W | T |

|---|---|---|---|---|---|

| 0603 | 180±2 | 60±1 | 13±1 | 9±1 | 11.4±1 |

| 0805 | |||||

| 1206 |

Packaging

| Type | LMS06 | LMS08 | LMS12 |

|---|---|---|---|

| Quantity(pcs) | 5,000 | 4,000 | 4,000 |