0603FA-R750HF

Fast Acting | 0.063x0.032 inch

Thick Film Chip Fuses

0603FA Series are the fuses set the industry standard for performance, reliability and quality. The solder-free design provides excellent on-off and temperature cycling characteristics during use and also makes our SMD fuses more heat and shock tolerant than typical subminiature fuses.

Features

AEC-Q200 Automotive Grade Certified

Compatible with reflow and wave solder

Excellent environmental integrity

One time positive disconnect

Lead Free and Halogen free material

Appications

- Flat panel displays and televisions

- Automotive infotainment and ECU

- Computer servers

- Portable electronics

- Mobile device chargers

Electrical Characteristics

| Amp Rating (A) | % of Amp Rating | Opening Time |

|---|---|---|

| 0.25 ~ 5A | 100% | 4 hours min |

| 0.25 ~ 5A | 200% | 5 seconds max |

Specification

| Part Number | Amp Rating (A) | Voltage Rating (V) | Interrupting Rating | Typical Cold Resistance (Ω) | Typical Melting I²t (A²s) | Typical Voltage Drop (V) | Marking Code |

|---|---|---|---|---|---|---|---|

| 0603FA-R250HF | 0.250 | 63 | 63V@50A | 3.250 | 0.0004 | 0.893 | D |

| 0603FA-R375HF | 0.375 | 63 | 63V@50A | 1.800 | 0.0009 | 0.587 | E |

| 0603FA-R500HF | 0.500 | 63 | 63V@50A | 1.070 | 0.001 | 0.582 | F |

| 0603FA-R750HF | 0.750 | 63 | 63V@50A | 0.470 | 0.009 | 0.427 | G |

| 0603FA-1HF | 1.00 | 63 | 63V@50A | 0.250 | 0.010 | 0.335 | H |

| 0603FA-1.5HF | 1.50 | 63 | 63V@50A | 0.150 | 0.040 | 0.270 | K |

| 0603FA-2HF | 2.00 | 63 | 63V@50A | 0.075 | 0.115 | 0.160 | N |

| 0603FA-2.5HF | 2.50 | 63 | 63V@50A | 0.047 | 0.140 | 0.145 | O |

| 0603FA-3HF | 3.00 | 63 | 63V@50A | 0.035 | 0.280 | 0.130 | P |

| 0603FA-3.5HF | 3.50 | 63 | 63V@50A | 0.027 | 0.500 | 0.130 | R |

| 0603FA-4HF | 4.00 | 63 | 63V@50A | 0.018 | 0.600 | 0.120 | S |

| 0603FA-5HF | 5.00 | 63 | 63V@50A | 0.012 | 1.900 | 0.110 | T |

- DC Interrupting Rating (Measured at rated voltage, time constant of less than 50 microseconds, battery source)

- DC Cold Resistance are measured at <10% of rated current in ambient temperature of 25 degrees

- Typical Pre-arcing I2 t are measured at 10In Current Specifications are subject to change without notice. Application testing is strongly recommended.

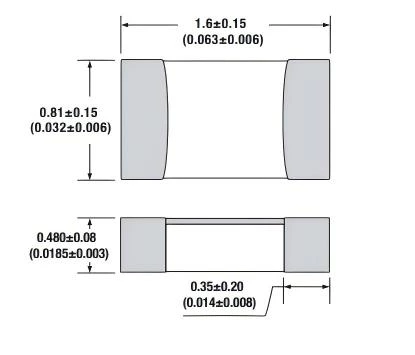

Dimension

Unit: mm/inch

Pad layout

Packaging

- Quantity: 5 000pcs

- 8mm wide tape on 178mm(7 inch) diameter reel -specification EIA Standard 481.

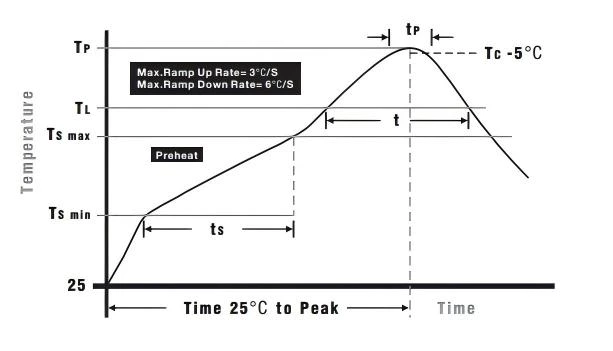

Soldering Parameters

Wave Soldering: 260°C, 10 seconds max.

Infrared Reflow: 260°C, 30 seconds max.

| Preheat Heat | |

|---|---|

| Temperature min (Tsmin) | 150°C |

| Temperature max(Tsmax) | 200°C |

| Time (Tsmin to Tsmax) (ts) | 60 -120 seconds |

| Average ramp-up rate(Tsmax to Tp) | 3°C/second max. |

| Liquidous temperature (TL) | 217°C |

| Time at liquidous(tL) | 60 -150 seconds |

| Peak temperature(Tp) | 260+0/-5°C |

| Time within 5°C of actual peak Temperature (tp) | 10-30 seconds |

| Average ramp-down rate (Tp to Tsmax) | 6°C/second max. |

| Time 25 °C to peak temperature | 8 minutes max. |

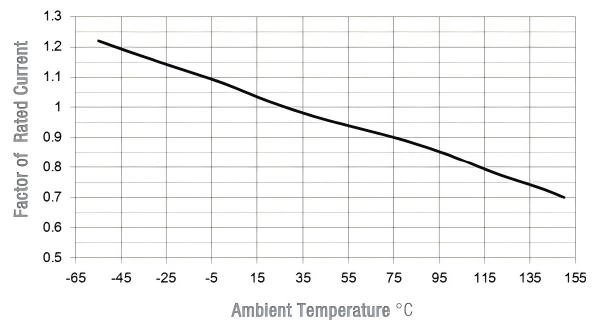

Temperature Derating Curve

- Normal ambient temperature: 23+/-3℃

- Operating temperature: -55 ~ 150℃, with proper correction factor applied

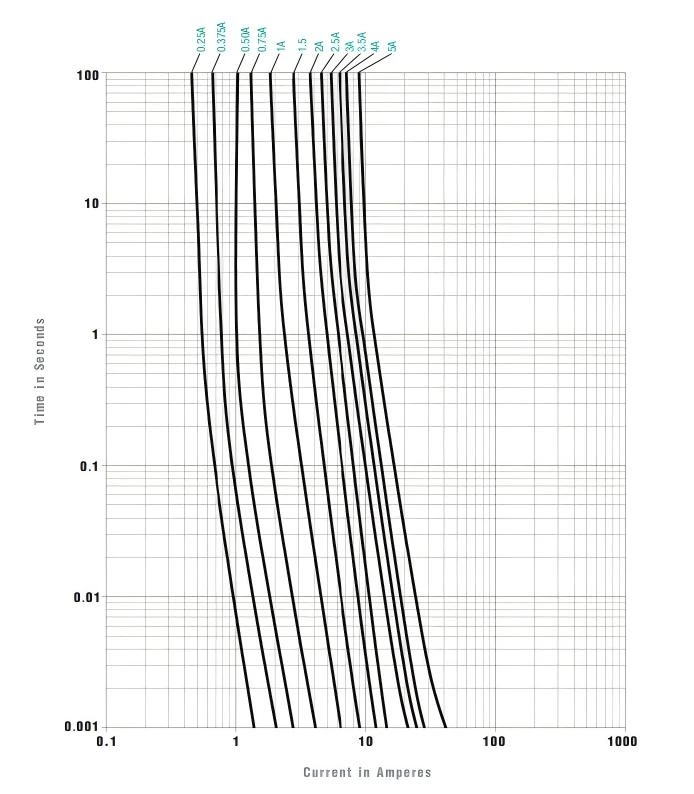

Average Time Current Curves