0603TD-1.5A-L

Ultra-Thin Fuse | 0.06x0.03’’

Time Delay series Thin Film Chip Fuse

Features

- Low DCR

- High inrush current withstanding capability

- High reliability

- Fiberglass enforced epoxy fuse body

- Copper termination with nickel and tin plating layer

- Halogen free, RoHS compliance & lead-free

Application

- Panel

- HDD

- Toy

- IoT

- Battery pack

- Finger print

- Smart lock

- Notebook

Electrical Characteristics

| % of Current Rating | Opening Time |

|---|---|

| 100% | 4hours min. |

| 200% | 5second max. |

| 300% | 0.2second max. |

Specifications

| Part No. | Current Rating(A) |

Voltage Rating (Vdc) |

Interrupting Rating |

Typical Cold DCR (Ω) |

Typical I2t (A2Sec)* |

Marking |

|---|---|---|---|---|---|---|

|

0603TD-1.5A-L

|

1.5

|

35 | 35A @35V |

0.05

|

0.082

|

N |

*Typical I2t: i.e. melting I2t at 0.001s of current rating

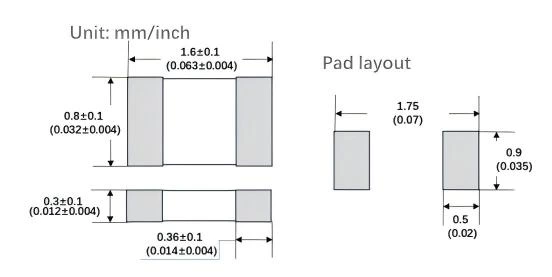

Dimension

Packaging

- Quantity: 5, 000pcs

- 8mm wide tape on 178mm (7 inch) diameter reel -specification EIA Standard 481

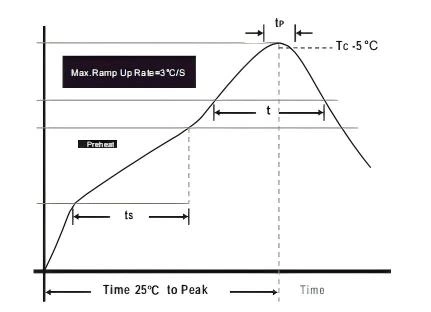

Soldering Parameters

Wave Soldering: 260°C, 10 secondsmax.

Infrared Reflow: 260°C, 30 seconds max.

IR Reflow Profile

| Preheat Heat | |

|---|---|

| Temperature min (Tsmin) | 150°C |

| Temperature max(Tsmax) | 200°C |

| Time (Tsmin to Tsmax) (ts) | 60 -120 seconds |

| Average ramp-up rate (Tsmax to Tp) | 3°C/second max. |

| Liquidous temperature (TL) | 217 °C |

| Time at liquidous (tL) | 60 - 150 seconds |

| Peak temperature(Tp) | 260°C |

| Time within 5°C of actual peak Temperature (tp) | 30 seconds |

| Average ramp-down rate (Tp to Tsmax) | 6°C/second max. |

| Time 25 °C to peak temperature | 8 minutes max. |

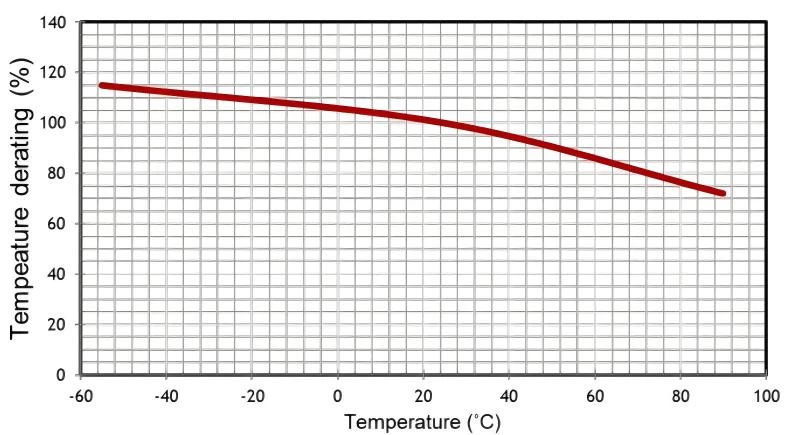

Temperature Effect on Current Rating

- Normal ambient temperature: 23+/-3℃

- Operating temperature: -55 ~ 105℃

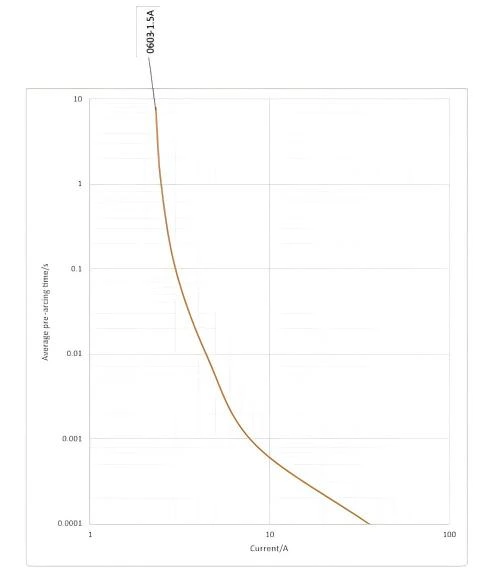

Average Time-Current curve