1206TD-15AS

Time Delay | 0.126x0.064 inch

Thick Film Chip Fuses

1206TD Series are the fuses set the industry standard for performance, reliability and quality. The solder-free design provides excellent on-off and temperature cycling characteristics during use and also makes our SMD fuses more heat and shock tolerant than typical subminiature fuses.

Features

- High inrush current withstanding capability

- AEC-Q200 Automotive Grade Certified

- Compatible with reflow and wave solder

- Ceramic and glass construction

- Excellent environmental integrity

- One time positive disconnect

- Lead Free and Halogen free material

Appications

- Flat panel displays and televisions

- Automotive infotainment and ECU

- Computer servers

- Portable electronics

- Mobile device chargers

- Power Battery Packs

Electrical Characteristics

| Rated Current | 1.0 In | 2.5 In | 3.0 In | 3.5 In | 10 In |

|---|---|---|---|---|---|

| 4.5A ~ 5A | 4 hours min. | 5 sec max. | 0.1 sec – 3 sec | – | 0.2 ms – 20 ms |

| 6A ~ 40A | 4 hours min. | – | – | 5 sec max. | 0.2 ms – 20 ms |

Specifications

| Part Number | Ampere Rating (A) | Voltage / Interrupting Rating | Typical Cold Resistance (Ω) | Typical Melting I²t (A²Sec) | Typical Voltage Drop (V) | Marking Code |

|---|---|---|---|---|---|---|

| 1206TD-4.5AS | 4.50 | 72Vdc @ 50A 63Vdc @ 50A 32Vdc @ 50A |

0.027 | 2.65 | 0.164 | X |

| 1206TD-5AS | 5.00 | 0.022 | 4 | 0.145 | T | |

| 1206TD-6AS | 6.00 | 0.0145 | 12 | 0.140 | F | |

| 1206TD-7AS | 7.00 | 0.0105 | 14 | 0.130 | 7 | |

| 1206TD-8AS | 8.00 | 48Vdc @ 200A 36Vdc @ 200A 32Vdc @ 200A |

0.0070 | 16 | 0.123 | V |

| 1206TD-10AS | 10.0 | 0.0050 | 22 | 0.110 | U | |

| 1206TD-12AS | 12.0 | 0.0043 | 40 | 0.080 | W | |

| 1206TD-15AS | 15.0 | 0.0035 | 45 | 0.085 | Y | |

| 1206TD-20AS | 20.0 | 0.0022 | 50 | 0.080 | Q | |

| 1206TD-25AS | 25.0 | 0.00155 | 58 | 0.090 | L | |

| 1206TD-30AS | 30.0 | 0.00132 | 95 | 0.090 | Z | |

| 1206TD-40AS | 40.0 | 36Vdc @ 200A 32Vdc @ 200A |

0.00085 | 240 | 0.095 | XL |

- DC Interrupting Rating (Measured at rated voltage, time constant of less than 50 microseconds, battery source)

- DC Cold Resistance are measured at <10% of rated current in ambient temperature of 25℃

- Typical Pre-arcing I2 t are measured at 10In Current. Choice fuse for surge application (USB charger etc.), make sure the I2 t of fuse is 4 times than surge. Specifications are subject to change without notice. Application testing is strongly recommended

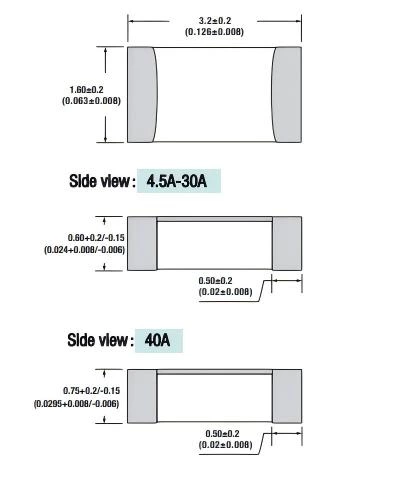

Dimension

Unit: mm/inch

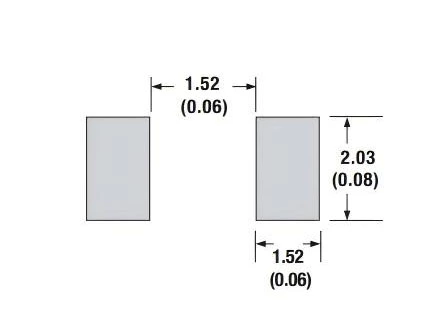

Pad layout

Packaging

- Quantity: 3 000pcs

- 8mm wide tape on 178mm(7 inch) diameter reel -specification EIA Standard 481.

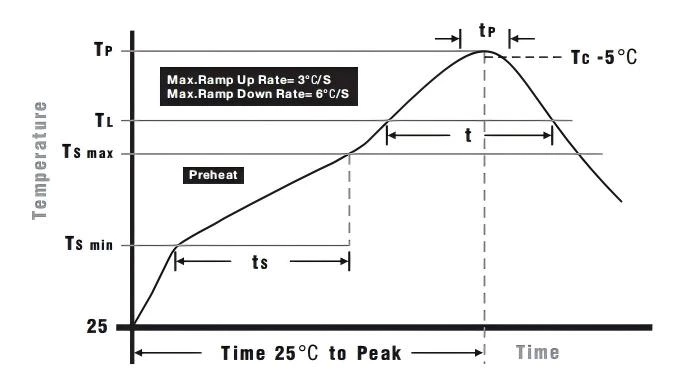

Soldering Parameters

Wave Soldering: 260°C, 10 seconds max.

Infrared Reflow: 260°C, 30 seconds max.

IR Reflow Profile

| Preheat Heat | |

|---|---|

| Temperature Min (Tsmin) | 150°C |

| Temperature Max (Tsmax) | 200°C |

| Time (Tsmin to Tsmax), ts | 60 – 120 seconds |

| Average Ramp-up Rate (Tsmax to Tp) | 3°C/second max. |

| Liquidous Temperature (TL) | 217°C |

| Time at Liquidous (tL) | 60 – 150 seconds |

| Peak Temperature (Tp) | 260 +0/-5°C |

| Time within 5°C of Peak (tp) | 10 – 30 seconds |

| Average Ramp-down Rate (Tp to Tsmax) | 6°C/second max. |

| Total Time (25°C to Peak) | 8 minutes max. |

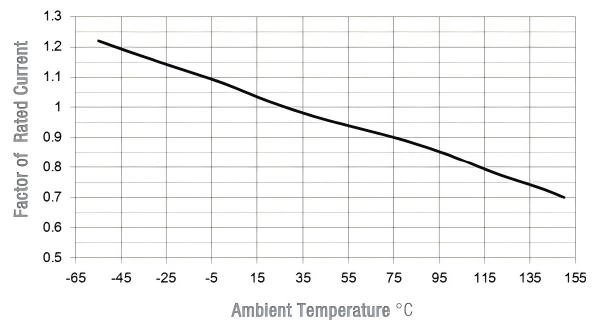

Temperature Derating Curve

- Normal ambient temperature: 23+/-3℃

- Operating temperature: -55 ~ 150℃, with proper correction factor applied

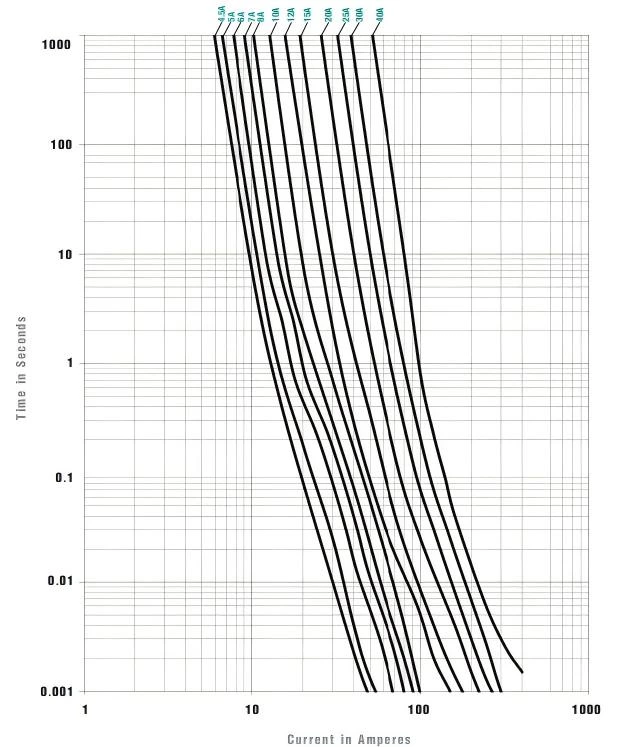

Average Time Current Curves