Current Shunt Resistor Selection Guide:High-Precision Shunts for EV Battery Management

1. Introduction

In electric vehicles (EVs), accurate and reliable current measurement is essential for battery safety, state-of-charge (SOC) estimation, and over-current protection. The BMS current shunt resistor (shunt resistor) provides an economical, linear, and fast-responding solution. This guide walks you through why shunt resistors are preferred in EV BMS, key selection criteria, comparisons with Hall sensors, a real-world EV case study, and a concise summary.

2. Why Choose a Shunt Resistor

(1)Cost and Size

Shunt resistors cost only cents each and occupy minimal PCB area, whether in SMD or stud-mount packages.

(2)Linearity and Speed

Ohm’s law (V = I × R) holds true across the full current range; response times can be in the microsecond range.

(3)High Precision

Combined with a 4-wire (Kelvin) connection and high-resolution ADC or amplifier, shunt resistors can achieve ±0.1 % measurement accuracy.

(4)Easy Integration

Shunts interface directly with amplifiers and microcontrollers, supporting SOC/SOH algorithms and rapid over-current detection.

3. Core Selection Dimensions

(1)Resistance Value & Voltage Drop

- Typical Range: 0.1 mΩ to 100 mΩ

- Design Target: 10 mV to 100 mV drop at maximum current

- Balance: Ensure the sense voltage fits your ADC input range while keeping energy loss acceptable

(2)Accuracy & Tolerance

- Tolerance Grades: ±1 %, ±0.5 %, ±0.1 %

- Impact: Directly influences SOC estimation error and over-current thresholds

- Recommendation: Use ±0.5 % or better for EV BMS applications

(3)Temperature Coefficient (TCR)

- Common Values: ±50 ppm/°C, ±25 ppm/°C

- Purpose: Minimizes drift due to ambient temperature changes

- Guideline: Select TCR ≤ 50 ppm/°C for stable performance across temperature

(4)Power Rating

- Formula: P = I² × R

- Safety Margin: At least 2× the calculated dissipation

- Typical Ratings: 1 W, 3 W, 5 W, or higher in metal-cased or stud-mount packages

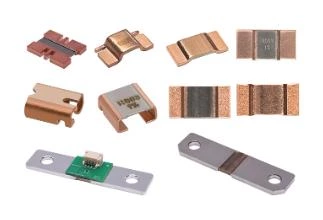

(5)Packaging & PCB Layout

- SMD Packages: 1206, 2512—ideal for automated assembly and medium currents

- 4-Wire (Kelvin) Shunts: Separate current-carrying and sense terminals to eliminate lead resistance errors

Layout Tips:

- Keep high-current traces short and wide for minimal losses and better cooling

- Route sense lines away from switching noise and place the amplifier close to the shunt

- Use copper pours or thermal vias to improve heat dissipation

4. Shunt Resistor vs. Hall-Effect Sensor

| Feature | Shunt Resistor | Hall-Effect Sensor |

|---|---|---|

| Cost | Low | Higher |

| Accuracy | Very high (±0.1 %–1 %) | Good (±1 %–3 %) |

| Response Time | Microseconds | Milliseconds |

| Size | Small | Larger |

| Isolation | Requires external isolation | Built-in galvanic isolation |

| Linearity | Excellent | Good |

- For 12 V–48 V EV BMS systems, shunt resistors are typically preferred for their cost, linearity, and speed. Hall sensors remain an option where galvanic isolation is mandatory.

5. Practical Case: Selection of Shunt Resistors for BMS in Electric Vehicles

(1)System Specs

- Battery pack voltage: 400 V

- Continuous discharge current: 200 A

- Peak transient current: 300 A

(2)Resistance & Drop

- Target drop: 50 mV

- Calculated R: 0.05 V / 200 A = 0.25 mΩ

(3)Power Dissipation

- Continuous P: 200² × 0.00025 = 10 W

- Recommended rating: ≥ 20 W

(4)Package & Layout

- Recommended package: 4-wire stud-mount metal alloy shunt for superior cooling and measurement accuracy

PCB layout:

- Wide, short copper traces for the current path, with multiple copper layers or pours

- Close-coupled sense traces to the amplifier, using shielded or twisted pairs

(5)Supporting Components

- Current amplifier: TI INA240 (isolated, high common-mode rejection)

- ADC: 24-bit delta-sigma ADC for maximum resolution and low noise

- PCB substrate: Metal-core or high-TG material for enhanced thermal management

6. Conclusion

Selecting the right current shunt resistor for an EV battery management system requires balancing resistance value, accuracy, thermal stability, power handling, and PCB layout. In our EV case, a 0.25 mΩ, ≥ 20 W, 4-wire stud-mount shunt combined with an isolated amplifier and high-resolution ADC delivers high-precision measurement with minimal energy loss. Reach out with your project details if you need customized resistor recommendations or layout advice.