Factors That Affect The Breaking Capacity Of Chip Fuses

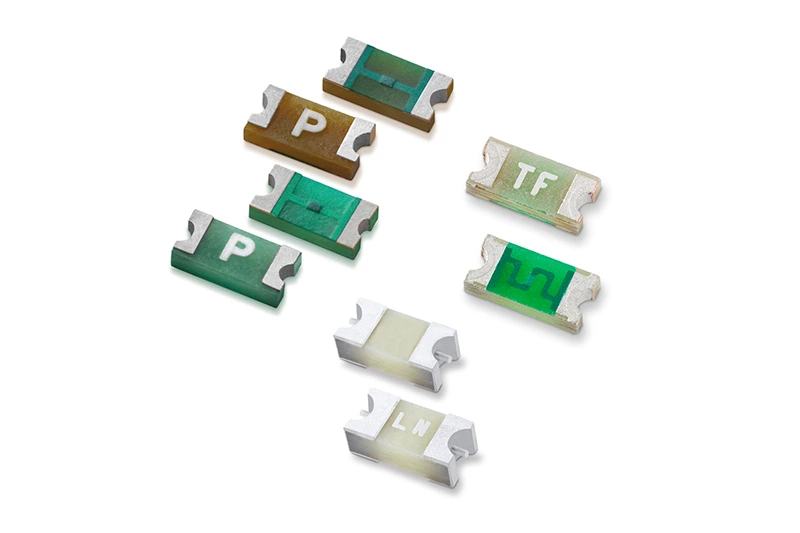

Chip fuses play a critical role in modern electronics by providing fast and reliable overcurrent protection in compact PCB layouts. One of the most important performance indicators of a chip fuse is its breaking capacity—the maximum fault current the fuse can safely interrupt without causing damage to the circuit or the surrounding components.

Understanding what influences breaking capacity helps engineers choose the right fuse for different applications, from consumer electronics to automotive systems.

Below are the key factors that determine a chip fuse’s breaking capacity and how they impact real-world performance.

1. Fuse Element Material and Structure

The fuse element’s composition directly affects its melting behavior and ability to handle high fault currents.

Common material influences:

- Metal alloy types determine melting point and thermal conductivity.

- Thickness and width of the fusible link define how quickly the element melts under overload.

- Internal structure design (straight strip, serpentine pattern, multilayer) can increase surface area for heat distribution.

A stronger material or optimized structure allows higher breaking capacity without increasing size.

2. Substrate and Encapsulation Material

Chip fuses commonly use ceramic or epoxy substrates. Each material behaves differently under high energy:

- Ceramic substrates offer excellent heat resistance and insulation, supporting higher breaking currents.

- Epoxy-based fuses may have lower breaking capacity due to thermal limitations.

- Encapsulation quality impacts arc suppression—critical during high-current interruption.

Better thermal robustness equals better safety margin.

3. Arc Suppression Capability

When a fuse blows at high current, an electrical arc may form. Whether the fuse can suppress this arc safely determines its breaking capacity.

Key influences:

- Gap distance after the fuse element melts

- Material’s dielectric strength

- Internal air or filler composition

If the arc cannot be extinguished, the fuse may fail catastrophically.

4. Operating Voltage

Breaking capacity is always related to the maximum rated voltage.

At higher voltage:

- The arc is harder to extinguish

- Clearances must be larger

- Fuse materials must withstand stronger electric fields

Thus, a fuse with the same physical size may have high breaking capacity at 12 V but not at 125 V.

5. Ambient Temperature and Heat Dissipation

Temperature changes the fuse’s electrical and thermal behavior:

- High ambient temperature lowers breaking capacity because the fuse element is already closer to its melting point.

- Poor PCB heat dissipation raises internal temperature and further reduces safety margins.

- Thermal cycling over long-term use may cause material fatigue and lower endurance.

Engineers should always consider derating curves provided by the manufacturer.

6. PCB Layout and Mounting Conditions

A chip fuse does not operate alone—its environment matters.

Factors include:

- Distance to high-current traces or hot components

- Copper pad size, which influences heat spreading

- Solder joint quality—poor joints increase resistance and generate more heat

- Vibration and mechanical stress, especially in automotive and industrial equipment

Good PCB layout can significantly improve the fuse’s short-circuit performance.

7. Fault Current Characteristics

Different circuits produce different fault behaviors:

- Peak inrush current (e.g., capacitive loads)

- DC vs. AC fault currents

- Duration and waveform of the short circuit

Fuses must be tested with the worst-case scenario, not average load.

Conclusion

Breaking capacity is a critical specification that determines whether a chip fuse can safely handle real-world fault conditions. Material selection, structure, voltage, temperature, and PCB layout all play significant roles in how a fuse behaves during high-current events.

By understanding these influencing factors, engineers can choose chip fuses that ensure system reliability, prevent catastrophic failures, and meet industry safety standards—especially in demanding applications like automotive electronics, consumer devices, and industrial controllers.