Brick Fuses High performance Industrial Fuses Selection And Application Guide

In modern power distribution and industrial control, the industrial brick fuse stands out for its high interrupting capacity, reliability, and ease of maintenance. It is the preferred protective device for distribution panels, motor protection, and transformer safeguarding. This guide covers core specifications, industry applications, selection criteria, and common questions to help engineers and operations teams quickly master brick fuse procurement and layout.

What are Brick Fuses

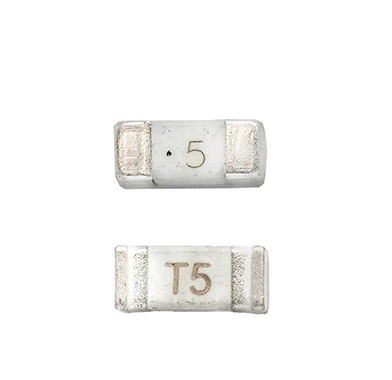

Brick Fuses, also known as NH fuses or modular fuses, are typically composed of a rectangular ceramic or high-strength polymer body and metal end caps. Their design objective is to interrupt high current faults within a few milliseconds, thereby protecting circuits and equipment and reducing fault losses.

Features

- Voltage Ratings – up to 600 VAC / 125 VDC

- Amp Ratings – up to 30A

- Multiple Safety Agency Approvals

- Case Sizes from 2410 to 4717

- Operating Temperature: -55°C to +125°C

- Mil-Std 202G Environmental Compliant

How to choose Brick Fuses

Purchasing Brick Fuses (module fuses) is not merely about choosing a current value. It also requires comprehensive consideration of electrical parameters, load characteristics, application environment and safety certifications. The following is a systematic selection process for Brick Fuses, which can help engineers or purchasers precisely match requirements and improve the security and efficiency of the system.

Target applications

- Battery chargers

- power supplies

- modems

- routers

- consumer electronics

- PoE

- PoE+

- Backplane short circuit protection

SMP type provides lightning surge withstand and 600 VAC power cross protection.

Maintenance and regular inspection

Visual inspection (monthly/quarterly)

- Observe the fuse status through the indicator window;

- Check whether the end caps and fuse holders have overheating, discoloration, deformation or carbonization.

Thermal imaging inspection (annually)

- Use an infrared thermal imager to scan terminals and wires. If hot spots (with a temperature difference of ≥10℃) are found, handle them promptly.

Tightness check (half a year)

- Recheck the torque of all wiring screws to prevent poor contact caused by vibration loosening.

Cleaning and maintenance (depending on the on-site environment)

- Anti-static brushes are used for cleaning in industrial dust environments.

- In damp or corrosive areas, the metal end caps can be wiped with a contact cleaner to prevent oxidation.

Emergency response and replacement procedures for faults

Identify the faulty fuse:

- Check the instruction label and number, and confirm the fuse position.

- Use a multimeter to measure and confirm that it has been disconnected.

Safe power-off: Follow the three-level power-off procedure and lock the relevant switches.

Replacement operation:

- Wear insulating gloves and goggles;

- Replace with new products of the same model and characteristics. It is strictly prohibited to temporarily substitute non-standard products.

Test before power restoration:

- First, install the fuse and close the switch without load to confirm there are no abnormal sounds or sparks.

- After power-on, use a clamp meter to measure the current and phase-to-phase voltage to ensure the system is functioning properly.

Frequently Asked Questions (FAQ)

Q1: Why does my brick fuse trip unexpectedly?

A: You may be using a fast‑acting fuse and encountering normal inrush currents. Switch to a time‑delay brick fuse to tolerate startup surges.

Q2: How can I extend the lifespan of a brick fuse?

A: Ensure proper ventilation, avoid frequent overloads, and regularly inspect the fuse holder and contacts for corrosion or damage.

Q3: How do I coordinate brick fuses with circuit breakers?

A: Install brick fuses on individual feeder circuits and place a circuit breaker on the main bus. Follow fuse and circuit breaker coordination guidelines to achieve selective tripping.

Conclusion

By understanding the features and applications of brick fuses, including NH‑type brick fuses, molded brick fuses, and high‑interrupting brick fuses, and by following proper selection guidelines and panel layout practices, you can provide reliable overcurrent protection for power distribution, motor drives, inverters, and energy storage systems. Choosing the right brick fuse enhances system safety, reliability, and ease of maintenance.