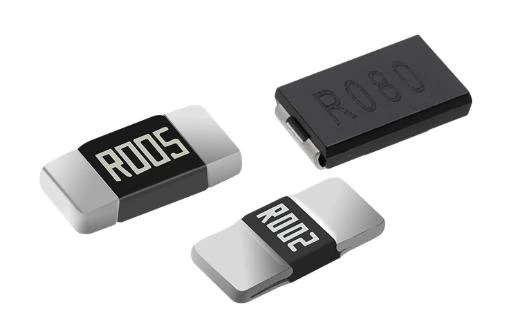

Metal Alloy Sensing Resistors: Your Complete Selection And Application Guide

Metal alloy shunt resistors are widely used for precise current monitoring and power management due to their extremely low resistance values, high precision, and excellent thermal stability.

What is a Metal Alloy Current Sensing Resistor?

Metal alloy shunt resistors are passive components that use ultra-low resistance metal alloy foils or wires to achieve precise current measurement by detecting the tiny voltage drop at both ends. Common materials include copper-nickel (CuNi), copper-chromium (CuCr), nickel-chromium (NiCr), etc., which can maintain the characteristics of small temperature coefficient, good heat dissipation and long service life under high current environment.

Core function: Convert current into measurable small voltage signals for precise collection by ADC, operational amplifier and other circuits.

main advantage

- Ultra-low resistance value (mΩ level)

- High precision (±0.1% to ±1%)

- Low temperature coefficient (±10 ppm/℃ to ±50 ppm/℃)

Why Metal Alloy Sensing Resistors Matter

Metal alloy sensing resistors are the heart of precise current measurement. A Metal Alloy Sensing Resistor converts electrical current into a tiny, measurable voltage drop, powering applications from electric vehicle BMS to industrial automation. Their inherent stability, low thermal drift, and high linearity ensure that your system can trust every millivolt of feedback.

Unveiling Materials and Structures

Common types of metal alloys

| Alloy Type | Characteristics | Typical Applications |

|---|---|---|

| CuNi | Low resistance, moderate cost, good stability | General current sensing |

| CuCr | High power handling, temperature resistance | Motor drives, industrial high-current measurement |

| NiCr | Very low temperature coefficient, higher temperature tolerance | Precision measurement in harsh environments |

Encapsulation and structural form

- Metal foil type: Alloy foil is adhered to ceramic or epoxy substrates, suitable for high-precision and low-temperature drift applications.

- Metal film type: A metal film is deposited on an insulating substrate by sputtering process, which can better control thickness and resistance value;

- Lead type: Sealed after winding with alloy wire, it has a high power density and is suitable for high-current detection.

- Bolt type: Designed with bolt holes, it can be directly hard-connected to the busbar or terminal block, and has extremely strong heat dissipation and current carrying capacity.

Advantages of Metal Alloy Sensing Resistors

- High Stability: Metal alloy sensing resistors resist thermal and aging drift, delivering consistent performance over time.

- Wide Bandwidth: Low inductance designs capture fast current transients, ideal for PWM‑driven motor control.

- Robustness: High power ratings and durable construction allow Metal Alloy Sensing Resistors to withstand harsh industrial environments.

- Cost‑Effectiveness: Compared to specialized current sensors, Metal Alloy Sensing Resistors offer precision at a lower price point.

Application fields of metal alloy sensing resistors

Electric Vehicle BMS

Use a 0.1 mΩ Metal Alloy Sensing Resistor with four‑wire Kelvin connections for battery state‑of‑charge accuracy and low heat generation.

Smart Grid Monitoring

Deploy high‑power Metal Alloy Sensing Resistors (10 W–50 W) in feeder lines to track load fluctuations and support dynamic demand response.

Industrial Automation

Integrate ±1 percent Metal Alloy Sensing Resistors in servo drives and PLC current loops to ensure precise torque control and protect against overcurrent.

Power Inverters & UPS

Incorporate Metal Alloy Sensing Resistors in DC bus circuits for rapid fault detection and energy‑efficient power conversion.

Troubleshooting Tips

- Overheating: Verify your Metal Alloy Sensing Resistor’s power rating and improve PCB thermal paths.

- Drift Over Temperature: Select a lower‑TCR alloy and implement firmware‑based temperature compensation.

- Noise Spikes: Use decoupling capacitors and maintain separation between power and sense planes.

FAQ

Q1: Why is a low TCR current sensing resistor chosen?

A1: A low TCR can reduce the impact of environmental temperature changes on measurement accuracy and ensure long-term stability.

Q2: How can the self-heating error of the shunt resistor be reduced?

A2: Increase the rated power margin, optimize the heat dissipation design, or parallel multiple small resistance values to share the power consumption.

Q3: How to choose between bolt-type and surface-mount type current sensing resistors?

A3: Bolt-type is preferred for high current or high power consumption scenarios; surface-mount film type can be chosen for space-constrained, low-power measurement applications.

Conclusion

Whether you need sub‑milliohm accuracy or high‑power robustness, Metal Alloy Sensing Resistors deliver unmatched precision, stability, and cost efficiency. By carefully selecting resistance value, tolerance, power rating, and following best‑practice layout and thermal management guidelines, you’ll equip your system with the most reliable current sensing solution available. Invest in Metal Alloy Sensing Resistors today for safer, more efficient, and higher‑performance designs.