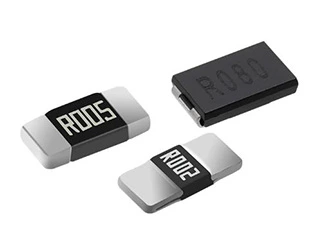

Prosemi CSR ALMJ12 Current Sensing Resistors For Automotive Applications

Characteristics of Prosemi Almj12 Current Sensing Resistor

Below, from the four aspects of “proprietary processing technology achieving ultra-low resistance,” “ultra-low inductance,” “low thermoelectric EMF,” and “metal material,” briefly explain the advantages and implementation mechanisms of current-sensing resistors:

Proprietary Processing Technology Achieving Ultra-Low Resistance

- Uses precision stamping, etching, or laser-cutting processes to form an extremely thin and uniform resistive film layer on the substrate;

- Through multiple tightly controlled steps that manage film thickness and geometry, the resistance value can be tuned accurately down to micro-ohm or even lower levels;

- Highly automated production with in-line testing ensures batch-to-batch consistency and ultra-tight tolerances (±0.1% or better).

Ultra-Low Inductance

- Implements a flattened, symmetrical element layout to minimize loop area in the conductor path;

- Adopts SMD packages or flat bolt-on structures that lie close to the PCB’s ground plane copper for heat dissipation while shortening the current path;

- Uses multi-layer complementary routing and equivalent-impedance optimization to suppress parasitic inductance, meeting fast-dynamic measurement requirements.

Low Thermoelectric EMF

- Chooses alloys with very low Seebeck coefficients (e.g., CuNi, Manganin);

- Uses identical or closely matched metals for both the resistor element and its terminals to minimize junction thermoelectric voltages;

- Strictly controls soldering/crimping temperatures and durations to avoid localized overheating that would introduce EMF offsets.

Metal Material

- Selects high-thermal-conductivity, high-strength metal alloys as the base, balancing mechanical robustness and thermal management;

- Provides a metal housing or terminals that can directly couple thermally to heatsinks, chassis, or large PCB copper pours for efficient heat removal;

- Offers excellent shock, vibration, and corrosion resistance, suitable for harsh industrial or automotive environments.

Prosemi CSR Almj12 Current Sensing Resistor Parameter

| Parameter | Standard |

|---|---|

| Power Rating | 0.5W & 1W |

| Resistance Value | 1W/1mΩ ~ 100mΩ;0.5W/101mΩ~200mΩ |

| Operating Temperature Range | -55 to +170°C |

| Component Temperature Coefficient (TCR) | ±50ppm/°C & 380ppm/°C |

| Maximum Working Voltage (V) | (P×R)¹/² |

| Rating Current (A) | (P/R)¹/² |

P = Power Rating; R = Resistance Value

Prosemi CSR Almj12 Current Sensing Resistor Character

| Item | Test Condition / Methods | Limited | Standard |

|---|---|---|---|

| Resistance | Measuring resistance value at room temperature 25℃±5℃ | Refer to Spec | IEC60115-1 4.5 |

| Temperature Coefficient of Resistance | TCR = (R-R0)/R0(T2-T1)×10⁶ R0: resistance at room temperature R: resistance at 125℃ T1: room temperature T2: 125℃ |

Refer to Spec | MIL-STD-202 Method 304 |

| Short Time Overload | 5× rated power for 5 seconds | ≤±0.5% | MIL-STD-202 Method 210 |

| Resistance to Soldering Heat | 260℃±5℃ for 10±1 sec | ≤±0.5% | MIL-STD-202 Method 210 |

| Temperature Cycling | -55℃ (30min) / +125℃ (30min), 1000 cycles | ≤±0.5% | MIL-STD-202 Method 107G |

| Low Temperature Storage | -55℃ for 1000 hours, no power | ≤±0.5% | MIL-STD-26E |

| High Temperature Storage | 125℃ for 1000 hours, no power | ≤±1% | IEC60115-1 4.25 |

| Bias Humidity | +85℃, 85% RH, 10% bias, 1.5h ON / 0.5h OFF, 1000 hours | ≤±0.5% | MIL-STD-202 Method 103 |

| Joint Strength of Solder | Soldered on bending test plate, load applied in center, measure resistance variance | ≤±0.5% | JIS-C5201 |

| Solderability | 245±5℃ solder, dipping 3±1 sec | Solder coverage ≥95% | IEC60115-1 4.17 |

| Load Life | 1000 h at 70℃, 1.5h ON / 0.5h OFF | ≤±1% | JIS-C5201 |

| Operational Life | 125℃±3℃, 1000 hours at rated power | ≤±0.5% | MIL-STD-202 Method 108 |

For more detailed specifications, operating temperature range, etc., you can visit our website homepage. Our company offers a wide range of electronic components and free sample trials. If you wish to apply for PROSEMI current detection resistors, overcurrent protection devices, or overvoltage protection devices for your project, please fill out the form below. We will promptly send the samples to you according to the delivery schedule. Welcome to order PROSEMI samples!