Cost-Effective Shunt Resistors Comparison: Performance vs Cost

Why Choosing the Right Shunt Resistor Matters

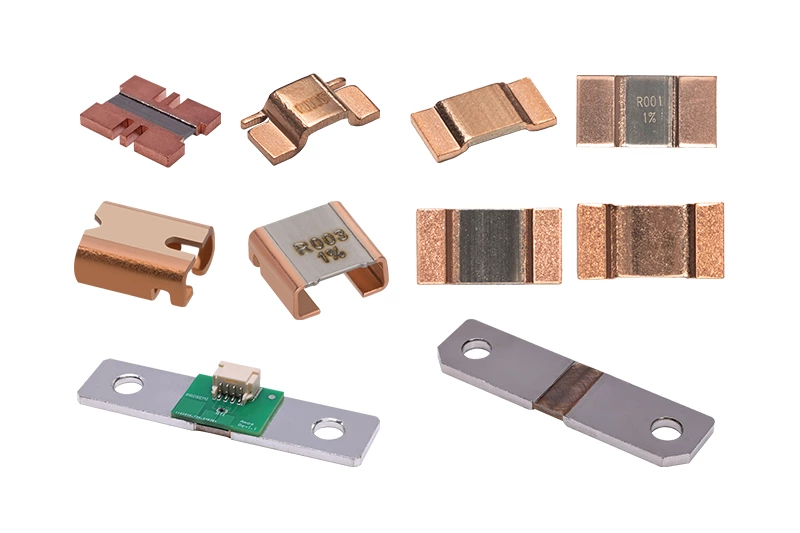

Shunt resistors are critical components in current sensing applications, ensuring accurate measurements and reliable system operation. The market offers a wide variety of options—from high-precision metal foil resistors to conventional thick-film types—each differing in cost, accuracy, and thermal stability.

However, not all projects require the highest-end specifications. For most engineers and procurement professionals, the real challenge is finding the optimal balance between cost and performance.

Our cost-effective shunt resistors are designed to meet this need. Through optimized materials, precise manufacturing, and strict quality control, they deliver stable electrical performance at a reasonable cost, making them ideal for battery management systems, power modules, motor controllers, and industrial electronics.

What Makes a Shunt Resistor Cost-Effective?

A truly cost-effective shunt resistor balances accuracy, reliability, and price. Key considerations include:

Electrical Performance vs Price

Tolerance: ±1%, ±0.5%, or ±0.1% for high-accuracy applications

such as PSRP12/PSRP25/APSRP25etc.

For more information, please.

Temperature Coefficient (TCR): 50–200 ppm/°C(such as PSRP27/PSRP27/APSRP39 etc.)

Stability: Resistance drift over time should remain minimal

Power Rating and Thermal Stability

Proper power rating ensures safe operation without oversizing

Avoiding overdesign helps reduce unnecessary costs

Consistency and Supply Reliability

Batch-to-batch uniformity ensures predictable system performance

Reliable supply chain is essential for production-scale projects

Comparison of Shunt Resistor Types

Metal Alloy vs. Thick Film Shunt Resistors

| Feature | Metal Alloy Shunt Resistors | Thick Film Shunt Resistors |

|---|---|---|

| Resistance Stability | Excellent, minimal drift over time | Moderate, more variation |

| Tolerance | ±1%, ±0.5%, optional ±0.1% | Typically ±1% to ±5% |

| Temperature Coefficient (TCR) | 50–200 ppm/°C | 200–500 ppm/°C |

| Thermal Performance | Stable under high thermal stress | Sensitive to temperature rise |

| Power Handling | Medium to high | Low to medium |

| Long-Term Reliability | High, suitable for continuous operation | Moderate |

| Cost Level | Moderate and well-balanced | Low |

| Typical Applications | BMS, power modules, industrial control | Consumer electronics, low-power devices |

Why This Matters:

While thick film resistors may offer lower upfront cost, their higher TCR and thermal sensitivity often limit long-term stability.

Metal alloy shunt resistors, by contrast, deliver more predictable performance, especially in environments with fluctuating temperatures or continuous current loads.

Low-Ohmic vs. High-Precision Shunt Resistors

| Feature | Low-Ohmic Shunt Resistors | High-Precision Shunt Resistors |

|---|---|---|

| Resistance Range | 0.5–10 mΩ | 0.01–1 Ω |

| Tolerance | ±1% | ±0.1% or better |

| TCR | 50–200 ppm/°C | 15–50 ppm/°C |

| Cost | Low to medium | High |

| Typical Use Cases | Power systems, BMS, converters | Precision instrumentation |

Engineering Perspective

High-precision shunt resistors offer excellent accuracy and ultra-low TCR, making them well-suited for applications that demand extremely tight measurement tolerances, such as precision instrumentation or calibration-grade systems. From a performance standpoint, they deliver outstanding stability and measurement consistency.

However, this level of precision often comes with a significantly higher cost, which may exceed the practical requirements of many industrial and power-related applications. In scenarios where ultra-low drift is not mission-critical, the added expense may not translate into proportional system-level benefits.

In contrast, cost-effective low-ohmic shunt resistors are engineered to provide a balanced combination of accuracy, thermal stability, and reliability, meeting real-world performance needs without unnecessary overengineering. This makes them an ideal choice for applications that prioritize stability, scalability, and cost efficiency while still maintaining dependable current sensing performance.

Application-Focused Advantages

Our metal alloy shunt resistors are especially suitable for a variety of applications. These applications demand controlled tolerance, stable TCR, and long-term reliability, especially under thermal cycling and continuous operation. Below are recommended models for each scenario:

| Application | Recommended Economic Models | Automotive Grade |

|---|---|---|

| Battery Management Systems (BMS) | PSRP12, APSRP12, PSRP25, APSRP25 | APSRP12, APSRP25 |

| Power Supplies and DC-DC Converters | PSRP27, APSRP27, PSRP25, APSRP25 | APSRP27, APSRP25 |

| Industrial Automation and Motor Control | PSRP39, APSRP39, PSRP27, APSRP27 | APSRP39, APSRP27 |

| Energy Storage and Charging Systems | PSRP40, APSRP40, PSRP39, APSRP39 | APSRP40, APSRP39 |

For other models, please visit the website or.

Notes:

- Models with an “A” suffix are automotive-grade, suitable for higher reliability and automotive certifications.

- All listed models are economical, low TCR, and reliable.

- For applications requiring extreme precision, consider high-precision series such as PHS or PSS.

If you need it, please fill out the form. We offer free trial packs.

Why choose prosemi's shunt resistor?

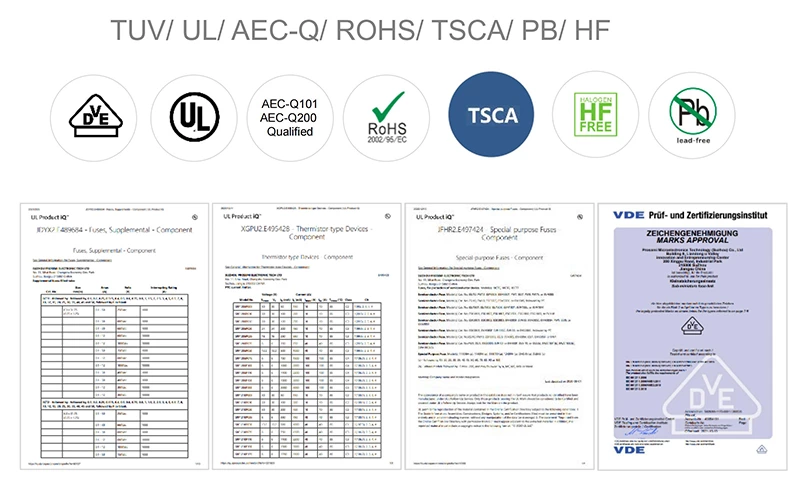

Quality and Certification

At PROSEMI TECHNOLOGY, we take pride in delivering not just products, but promises of unmatched quality and reliability.

- ISO 9001 and ISO 14001 - Our commitment to quality management and environmental management systems assures efficiency and sustainability in every process.

- IATF16949 Automotive System - We meet the stringent requirements of the automotive industry, emphasizing defect prevention and the reduction of variation and waste in the supply chain.

- AEC-Q200 Certification - This certification stands as a testament to our products' reliability and performance in automotive electronics.

Environmental protection

At our company, we believe that environmental responsibility is not just an obligation but a key factor in our long-term success. This certification is not just a badge we wear, but a philosophy we live by. We continually strive to implement environmentally sustainable practices which are reflected in every product we create and every process we undertake.

- HF ( Halogen Free ) - our resistors meet the stringent requirements of the HF (Halogen Free) standards, marking our allegiance to environmental safety and compliance.

- RoHS certification - Our compliance with RoHS means our products are free from lead, cadmium, mercury, and other substances that pose environmental and health risks.

- REACH certification - Our REACH compliance ensures that our products are safe, protecting both the environment and end-users from exposure to harmful substances.

Environmental Responsibility Is As Paramount As Quality

Reliable technology

Choose PROSEMI TECHNOLOGY as your trusted partner. Trust us to provide you with high-precision components that not only meet your exact standards but are also produced in an environmentally responsible way. Let's work together to achieve excellence in every product delivered, ensuring a sustainable and quality-driven future.

- PROSEMI is the only domestically-owned Chinese brand manufacturer that specializes in the design, development, and production of full-size (ranging from 0402 to 1206, 2512, and 5930) micro-resistance SMD precision alloy current-sense resistors across three different technology platforms.

- PROSEMI is the only domestic manufacturer capable of providing ultra-thin metal strip processing with a thickness of less than 0.3mm (as thin as 0.1mm) and has already started mass production and supply.

- PROSEMI is the exclusive domestic manufacturer offering electron beam continuous welding production line equipment for ultra-thin thicknesses above 3mm and below 1mm.

PROSEMI TECHNOLOGY - Committed to quality, committed to the planet.

Conclusion

In today’s fast-evolving electronics and power management landscape, selecting the right shunt resistor is crucial for both performance and cost-efficiency. Metal alloy shunt resistors provide an ideal balance of stable resistance, low TCR, and long-term reliability, making them suitable for applications ranging from battery management systems and power supplies to industrial automation and energy storage.

By leveraging advanced manufacturing processes, full-size SMD coverage, and automotive-grade options, our solutions ensure consistent quality, scalability, and value across diverse industries. Whether your priority is precision, durability, or cost-effectiveness, our metal alloy shunt resistors deliver dependable current sensing solutions that meet real-world requirements.

Choose wisely—engineered for performance, optimized for value.

to obtain your one-stop solution! Email address:nancy.chen@prosemitech.com