Role of Chip Fuses in Electric Vehicle Power Circuits

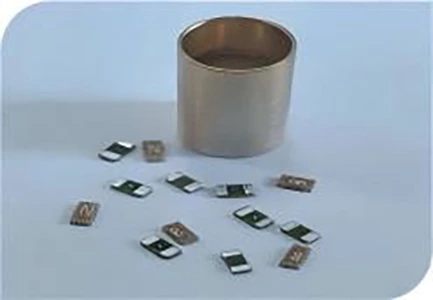

Electric vehicles (EVs) rely on complex power circuits that manage high voltages and currents. In such demanding systems, safety and reliability are essential. Chip fuses, also known as surface-mount fuses, play a vital role in protecting EV power electronics against overcurrent and short-circuit failures. These tiny yet powerful components ensure stable operation and safeguard costly electronic modules.

Why Overcurrent Protection Matters in EV Systems

EV power circuits handle various functions—from battery management and motor control to charging systems. Sudden overcurrent events caused by component faults, short circuits, or voltage spikes can lead to:

- Thermal damage to circuit boards

- Degradation of sensitive ICs

- Risk of fire or battery failure

A well-designed protection system must respond instantly to such faults. This is where chip fuses come in.

How Chip Fuses Work in EV Power Circuits

Chip fuses act as the first line of defense against excessive current. When the current exceeds a defined limit, the fuse element melts, interrupting the circuit and preventing further damage.

In EV applications, chip fuses are typically integrated into:

- Battery Management Systems (BMS) – for cell-level and pack-level protection

- DC/DC converters and inverters – to prevent overcurrent in power conversion circuits

- On-board chargers (OBC) – to safeguard AC/DC interfaces

- Vehicle Control Units (VCU) – for low-voltage logic and signal circuit protection

Their fast response and compact size make them ideal for high-density EV electronics.

Key Advantages of Chip Fuses in Electric Vehicles

- Compact and Lightweight – Perfect for space-limited EV modules.

- Surface-Mount Design (SMD) – Enables automated PCB assembly and consistent performance.

- High Breaking Capacity – Ensures circuit interruption even under high voltage and high current conditions.

- Stable Temperature Performance – Reliable in extreme automotive environments (–40°C to +125°C).

- Cost-Effective Protection – Provides a simple, passive safeguard without complex circuitry.

Selecting the Right Chip Fuse for EV Applications

When designing EV systems, engineers must consider key fuse parameters:

- Rated current and voltage – to match the expected load conditions.

- Breaking capacity – sufficient to interrupt potential fault current.

- Time-current characteristics – fast-acting or slow-blow, depending on circuit type.

- Environmental reliability – vibration, humidity, and thermal endurance under automotive standards (AEC-Q200).

Partnering with a professional fuse manufacturer ensures the right balance of protection, size, and durability.

Future Trends in Chip Fuse Technology

With the growing adoption of electric vehicles, chip fuses are evolving to support:

- Higher voltage ratings (up to 1,000V DC) for EV battery systems.

- Ultra-low resistance designs to minimize power loss.

- Smart fuse monitoring integrated with diagnostic circuits for predictive maintenance.

Such innovations will make chip fuses even more critical in next-generation EV safety architectures.

Conclusion

Chip fuses may be small, but their role in electric vehicle power circuits is indispensable. By providing precise, reliable overcurrent protection, they help maintain vehicle safety, prevent costly failures, and ensure the long-term reliability of EV power systems.