Shunt Resistor vs Hall Effect Sensor

Accurate current measurement is critical to the performance and safety of modern power control systems, including electric vehicles, battery packs, solar inverters, and industrial power supplies.

Among the most widely used current sensing methods are shunt resistors and Hall effect sensors. While both solutions are effective, they differ significantly in accuracy, response time, isolation, and cost. This article compares shunt resistors vs Hall effect sensors to help engineers choose the right approach for their application.

How Each Technology Works

Shunt Resistor

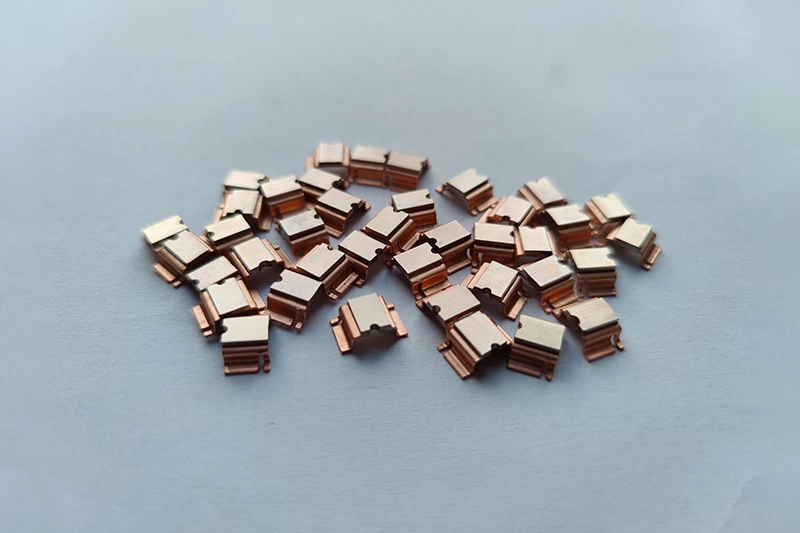

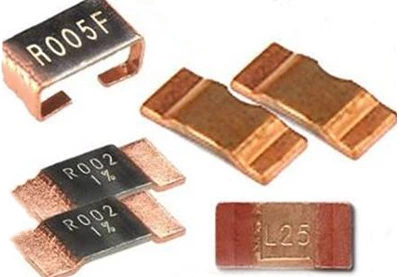

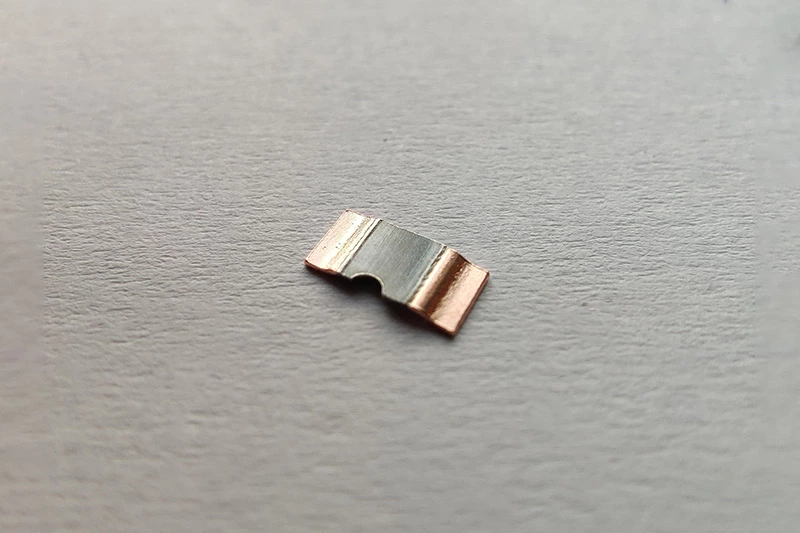

A shunt resistor measures current indirectly by converting it into a small voltage drop according to Ohm’s Law (V = I × R). The voltage is then amplified and interpreted by a control circuit or ADC (Analog-to-Digital Converter).

Key characteristics:

- Suitable for DC and low-frequency AC current measurement

- Direct, linear, and real-time response

- Typically made from metal alloy materials such as Manganin or NiCr for high stability

Hall Effect Sensor

A Hall effect sensor measures current by detecting the magnetic field generated around a conductor. A semiconductor element converts magnetic field strength into an electrical signal.

Key characteristics:

- Measures both AC and DC currents

- Provides galvanic isolation between the current path and sensing electronics

- Requires external power and signal conditioning

Comparison: Shunt Resistors vs Hall Effect Sensors

| Feature | Shunt Resistor | Hall Effect Sensor |

|---|---|---|

| Measurement Principle | Voltage drop (Ohm’s Law) | Magnetic field detection |

| Accuracy | High (±0.1% to ±0.25%) | Moderate (±1% to ±3%) |

| Response Time | Fast (microseconds) | Slower (milliseconds) |

| Temperature Stability | Excellent (Low TCR <50 ppm/°C) | Sensitive to temperature drift |

| Power Loss | Low (depends on resistance value) | Minimal |

| Size | Compact, simple design | Bulkier with magnetic core |

| Cost | Low to moderate | Higher |

| Isolation | No isolation (direct measurement) | Built-in galvanic isolation |

| EMI Sensitivity | Immune to magnetic interference | Can be affected by nearby magnetic fields |

| Maintenance | Simple and long-lasting | Requires calibration and drift correction |

Quick takeaway:

Shunt resistors excel in precision, speed, and long-term stability, while Hall effect sensors are preferred when electrical isolation is mandatory.

When to Use a Shunt Resistor

Shunt resistors are ideal for applications that demand high accuracy, stability, and cost efficiency.

Typical use cases include:

- Battery Management Systems (BMS) for EVs and energy storage

- DC/DC converters and power supplies

- Solar inverters and renewable energy systems

- Industrial monitoring and motor control

Advantages:

- Extremely precise and linear output

- Excellent temperature stability

- Compact and easy to integrate on PCBs

- Affordable for large-scale production

Metal alloy shunt resistors are especially effective where precision and long-term reliability are essential.

When to Use a Hall Effect Sensor

Hall sensors are better suited for applications that require electrical isolation or non-contact measurement, such as:

- High-voltage power lines

- Motor drive systems where physical connection is not possible

- Complex systems needing both AC and DC current sensing

Advantages:

- Provides safe galvanic isolation

- Works with high-voltage or high-current circuits

- Measures both AC and DC signals

Limitations:

- Lower accuracy and slower response

- More expensive and sensitive to magnetic interference

Why Metal Alloy Shunt Resistors Stand Out

Modern metal alloy shunt resistors are engineered to overcome the traditional drawbacks of temperature drift and long-term instability. They feature:

- Low TCR (<50 ppm/°C) for thermal stability

- Excellent long-term resistance stability

- High surge and overload capability

- Minimal thermal EMF for clean signal output

These advantages make them the preferred solution in EVs, BMS, energy storage, and industrial systems worldwide.

Final Thoughts

Both shunt resistors and Hall effect sensors play important roles in current sensing. However, for applications requiring high accuracy, fast response, and cost-effective implementation, metal alloy shunt resistors remain a highly reliable solution.

Choosing the right sensing method ultimately depends on system requirements, voltage level, and performance priorities.