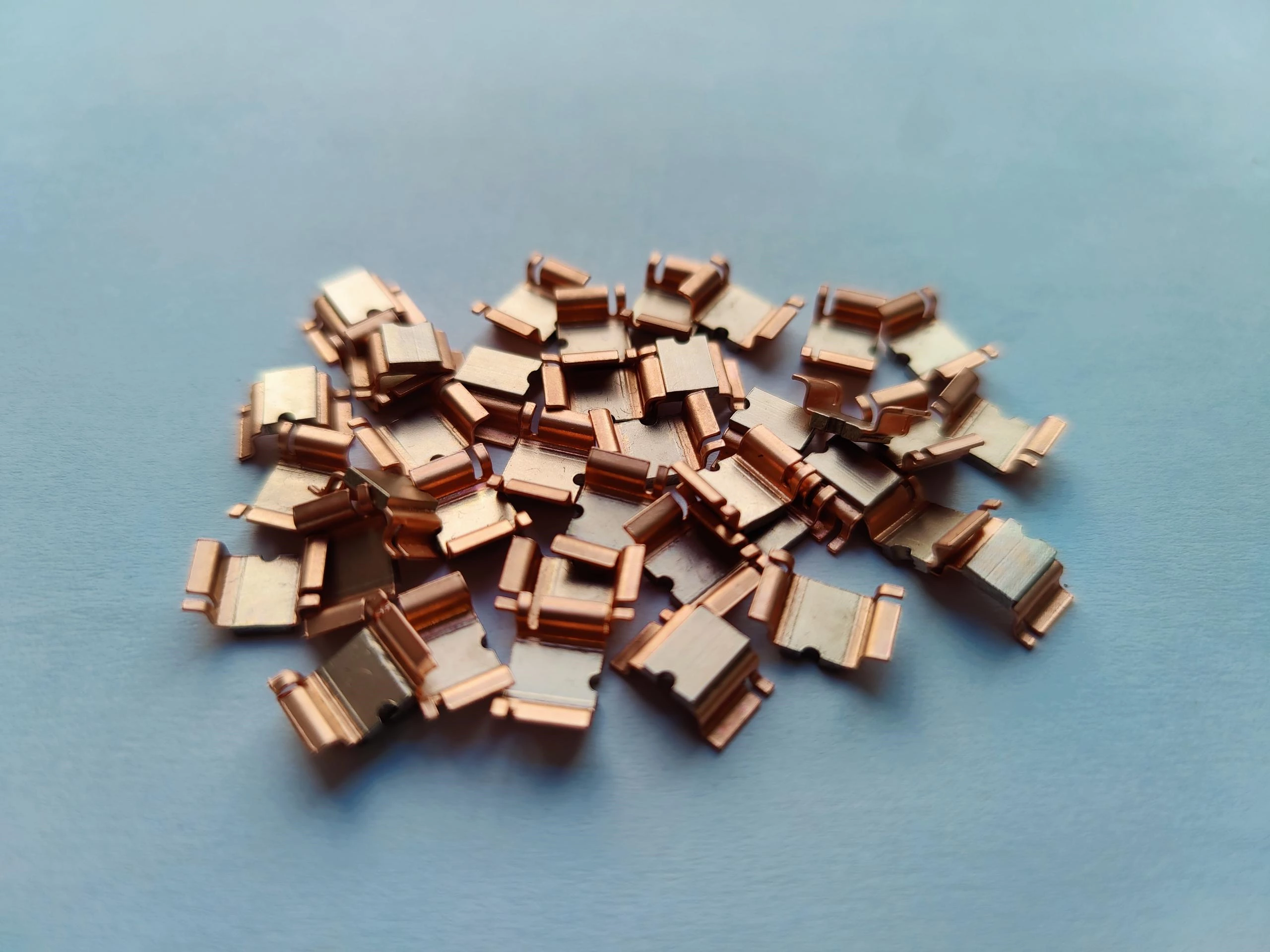

Why Metal Alloy Shunt Resistors Are The Best Choice For Precision Current Sensing

In high-precision electronic systems, accurate current measurement is the foundation of performance, safety, and efficiency. From electric vehicles (EVs) to industrial power management and battery monitoring systems (BMS), designers rely on precise current sensing to ensure stable operation.

Among the many options available, metal alloy shunt resistors stand out as the most reliable and accurate solution. Here’s why they are the preferred choice for precision current sensing.

What Is a Shunt Resistor?

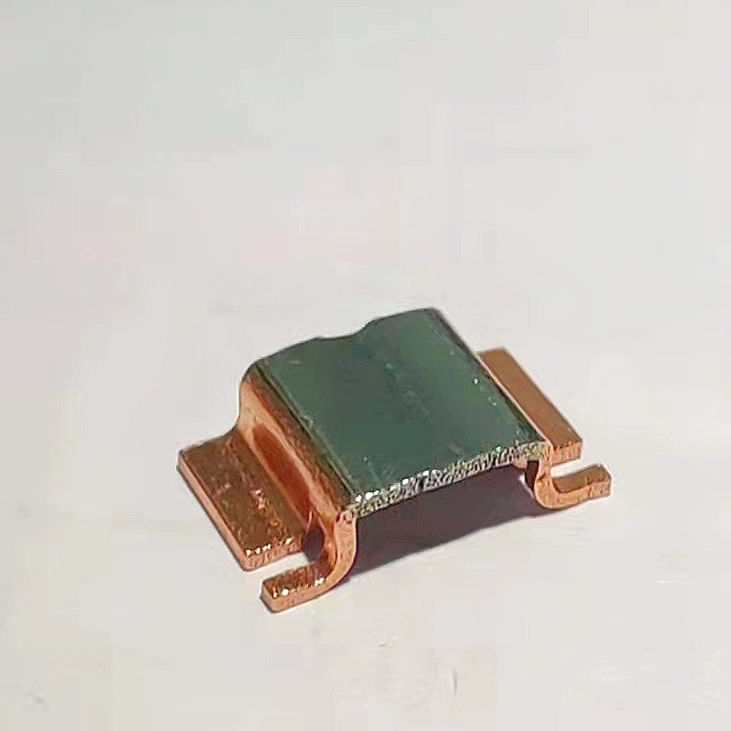

A shunt resistor is a low-resistance component used to measure current by converting it into a proportional voltage drop (according to Ohm’s Law: V = I × R).

This voltage is then detected and analyzed by control circuits or measurement devices.

Unlike sensors that rely on magnetic or Hall-effect principles, shunt resistors provide direct, linear, and highly accurate current measurements, even under demanding conditions.

Why Metal Alloy Materials Matter

The core advantage of a precision shunt resistor lies in the material.

Metal alloy resistors—typically made of Manganin (CuMnNi) or NiCr alloys—offer superior performance compared to conventional resistive materials like copper or steel.

Key benefits of metal alloy materials:

- Low Temperature Coefficient of Resistance (TCR): Resistance remains stable across wide temperature ranges, ensuring measurement accuracy.

- Excellent Long-Term Stability: The resistance value does not drift over time, maintaining consistent readings.

- Low Thermal EMF: Minimal thermoelectric voltage between terminals, avoiding offset errors.

- High Corrosion Resistance: Ideal for automotive, outdoor, or industrial environments.

These properties make metal alloy shunts ideal for precision and high-current applications.

Superior Temperature Stability

One of the biggest challenges in current sensing is temperature drift.

As current flows, resistors heat up, causing changes in resistance—and measurement errors.

Metal alloy shunt resistors are specifically engineered with low TCR (typically <50 ppm/°C), meaning their resistance changes very little with temperature. This ensures consistent performance in systems that operate across wide thermal ranges, such as:

- Electric vehicle powertrains

- Solar inverters and battery packs

- Industrial automation systems

Stable temperature behavior = consistent, accurate current measurement.

High Power Handling and Durability

Metal alloy shunt resistors are designed to handle large currents without excessive self-heating.

Their specialized construction—using robust alloy elements and copper terminations—provides:

- Excellent heat dissipation

- Low power loss (I²R)

- High mechanical strength for harsh conditions

This durability ensures long service life, even in heavy-duty or continuous current flow environments.

Low Thermal EMF for Measurement Accuracy

When two different metals are joined, a small voltage (thermal EMF) can develop at the junction, which can distort precision measurements. Metal alloy shunt resistors minimize this effect through carefully matched materials and optimized design.

The result? Clean, stable voltage signals—essential for millivolt-level sensing circuits in precision applications.

Ideal for Modern Power and Energy Systems

Today’s power systems require real-time, high-accuracy current monitoring for safety and efficiency. Metal alloy shunt resistors are the preferred choice for:

- EV Battery Management Systems (BMS)

- Energy Storage Systems (ESS)

- Industrial Power Supplies

- Solar and Renewable Energy Monitoring

- Smart Meters & Power Control Units

Their combination of precision, stability, and durability perfectly meets the needs of these demanding environments.

Comparison: Metal Alloy vs Conventional Shunt Resistors

| Feature | Metal Alloy Shunt Resistor | Conventional Resistor |

|---|---|---|

| TCR (Temperature Coefficient) | <50 ppm/°C | >200 ppm/°C |

| Long-Term Stability | Excellent | Moderate |

| Thermal EMF | Very Low | Higher |

| Power Handling | High | Medium |

| Accuracy | ±0.1% – ±0.25% | ±1% or more |

| Environmental Resistance | Strong | Limited |

Verdict: Metal alloy shunts clearly outperform conventional types in every precision category.

Final Thoughts

In precision current sensing, accuracy and stability are non-negotiable.

Metal alloy shunt resistors deliver both—offering low TCR, excellent heat resistance, and long-term reliability.

Whether you’re designing for electric vehicles, industrial automation, or renewable energy systems, choosing a metal alloy precision shunt resistor ensures dependable performance and peace of mind.