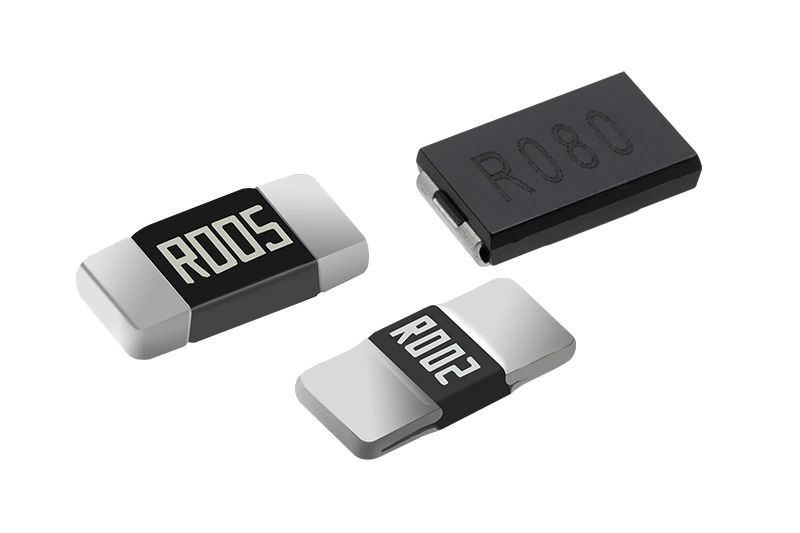

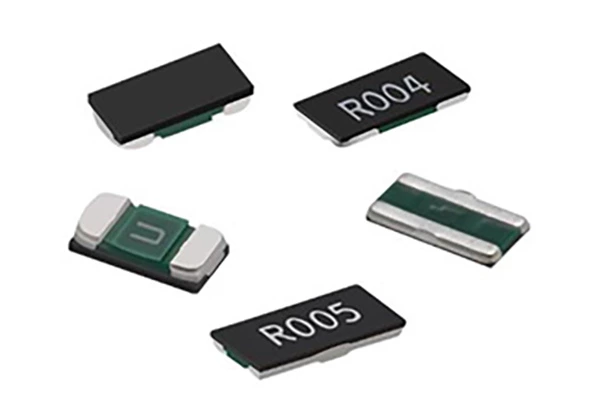

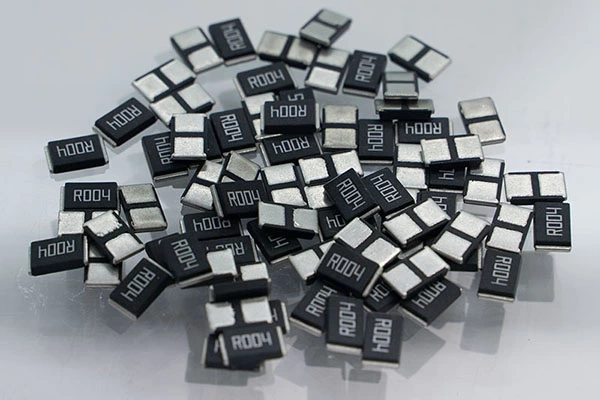

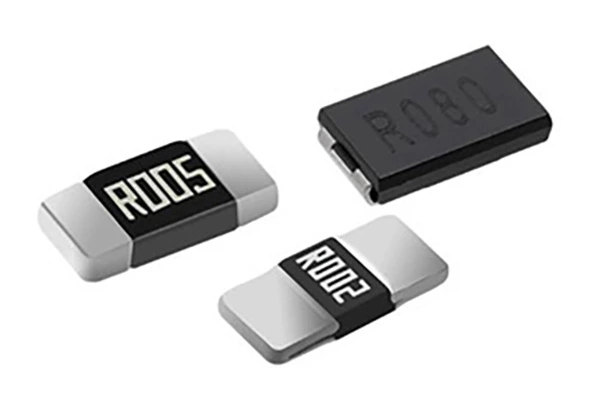

Buy Current Sense Resistor | Precision Sensing Resistors for Current Measurement

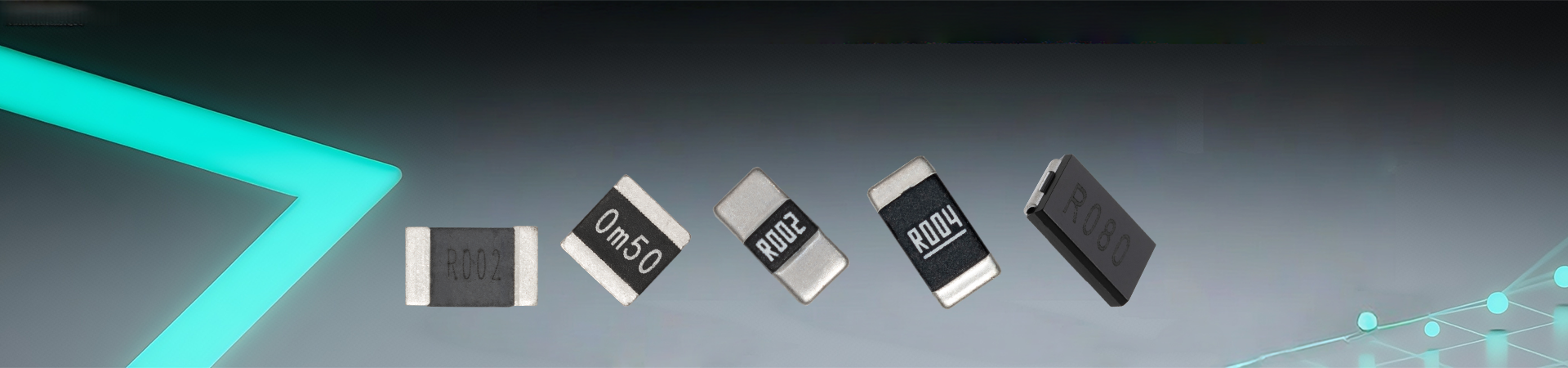

High-quality Current Sense Resistors (Shunt Resistors) for accurate current measurement. Ideal for power electronics, BMS, and industrial applications. Wide range, fast delivery!